I have a Bighorn TL3 that I’ve had for about 3 years now and I’ve always had some sort of extraction issue with it. I was sent a new extractor with spring and then a new bolt head neither of which seem to work. I’ve had two different gunsmiths one being patriot valley and the other a local gunsmith make me several barrels for it but I still have the same issue with having stuck cases. Has anyone else had this problem? My loads are pretty mild for 6 BR and 6 Creedmoor but I’m still having this issue.

- Thread starter racer95

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuck how? Like exactly how does it present?

The extractor will come over the case head leaving the fired piece of brass in the chamber of the rifle. If I remove the mag, apply torque outwards towards the chamber as I cycle to bolt again it seems to pull the case out every time. But this is an issue during matches as I don’t have time to do that.

Check for sharp edges/burrs under the extractor. I have TL-2’s (never had extraction issues), but had to clean up the extractors. Bighorns are real nice and from my perspective, this is a very minor issue. But then again, I’ve never had FTE issues....The extractor will come over the case head leaving the fired piece of brass in the chamber of the rifle. If I remove the mag, apply torque outwards towards the chamber as I cycle to bolt again it seems to pull the case out every time. But this is an issue during matches as I don’t have time to do that.

Huh? Apply torque outwards... towards the chamber?The extractor will come over the case head leaving the fired piece of brass in the chamber of the rifle. If I remove the mag, apply torque outwards towards the chamber as I cycle to bolt again it seems to pull the case out every time. But this is an issue during matches as I don’t have time to do that.

Huh? Apply torque outwards... towards the chamber?

If I put my thumb on the bolt shroud, push it towards the chamber and pull back on the handle as if I’m trying to spin the bolt out of the action in the direction of the ejection port and then cycle the bolt again it will then usual extract the spent brass.

What brass are you using? Have you checked the headspace on the barrels you've been using?

For the 6 BR I’m using Lapua brass and for the 6 Creedmoor barrel I use Peterson brass. I’ve check head space with both Foster headspace gauges and PTG gauges they both seem to check out fine.What brass are you using? Have you checked the headspace on the barrels you've been using?

I had a lot of issues with my TL3 extractors.

I got the run around from customer service for a while.

I had heard that they had a revision to their 223 extractor, but I never got the official word from them.

So I ordered a new extractor from them and then sold all my bighorns. It was a much better company when AJ was running things.

I got the run around from customer service for a while.

I had heard that they had a revision to their 223 extractor, but I never got the official word from them.

So I ordered a new extractor from them and then sold all my bighorns. It was a much better company when AJ was running things.

I’d really like this action to work out but after a new extractor and new bolt head were installed in two separate cases I’m not so sure it will.I had a lot of issues with my TL3 extractors.

I got the run around from customer service for a while.

I had heard that they had a revision to their 223 extractor, but I never got the official word from them.

So I ordered a new extractor from them and then sold all my bighorns. It was a much better company when AJ was running things.

Are these match chambers? And how many firings out of the brass from each cartridge/caliber?

I have similar issues as well. But seems to be an issue with a tight match chamber and work hardened brass in the case head area. The area where you cannot anneal.

The batch of brass has been fired 5X or 6X. Developed clickers on the 3rd or 4th firing. It's now going to be used in a SAAMI spec chamber instead. (6.5CM).

Norma and Lapua brass seems to handle this better.

Just my speculation.

I have similar issues as well. But seems to be an issue with a tight match chamber and work hardened brass in the case head area. The area where you cannot anneal.

The batch of brass has been fired 5X or 6X. Developed clickers on the 3rd or 4th firing. It's now going to be used in a SAAMI spec chamber instead. (6.5CM).

Norma and Lapua brass seems to handle this better.

Just my speculation.

They

My match brass has 2 to 3 fire cycles on them and my practice brass has 4 to 6 firings, both batches have the same issue. They are match chambers but it could be work hardening of the brass like you said. I wouldn’t think it would be that sensitive but I could be wrong, I most certainly have been before.Are these match chambers? And how many firings out of the brass from each cartridge/caliber?

I have similar issues as well. But seems to be an issue with a tight match chamber and work hardened brass in the case head area. The area where you cannot anneal.

The batch of brass has been fired 5X or 6X. Developed clickers on the 3rd or 4th firing. It's now going to be used in a SAAMI spec chamber instead. (6.5CM).

Norma and Lapua brass seems to handle this better.

Just my speculation.

i had this issue with alpha brass/whidden dies in 7SAW

without using a small base die i have the same problem

soft brass and a poorly made die allowing the base of the case (where case head separations occur) to expand too much

without using a small base die i have the same problem

soft brass and a poorly made die allowing the base of the case (where case head separations occur) to expand too much

What dies did you buy to correct this issue? I never thought about that being the problem.i had this issue with alpha brass/whidden dies in 7SAW

without using a small base die i have the same problem

soft brass and a poorly made die allowing the base of the case (where case head separations occur) to expand too much

I have no idea what any of that means.If I put my thumb on the bolt shroud, push it towards the chamber and pull back on the handle as if I’m trying to spin the bolt out of the action in the direction of the ejection port and then cycle the bolt again it will then usual extract the spent brass.

It’s hard to explain unfortunately without being able to see it.I have no idea what any of that means.

View attachment 7626918

i know exactly what you mean. and yeah without seeing it, its hard to pictureIt’s hard to explain unfortunately without being able to see it.

WTO sent me redding dies

My first thought is that your dies are not sizing the brass correctly for your chamber. You may want to consider a custom made die from someone like Whidden. Be sure to tell whoever you work with what the issue is you are trying to solve. I went through 3 sizing dies before I found one that I liked for my 6.5 Creedmoor.

A couple questions that may sound weird, I'm just brainstorming.

What torque value are you putting on the barrel?

Has your brass been fired through multiple chambers?

If you don't know your torque value, that my be the issue use 75-80 foot pounds.

If your brass has been through multiple barrels, run it all through a small base die to get it as close to new as possible. You can use a .308 small base for the BR stuff.

Just some ideas.

What torque value are you putting on the barrel?

Has your brass been fired through multiple chambers?

If you don't know your torque value, that my be the issue use 75-80 foot pounds.

If your brass has been through multiple barrels, run it all through a small base die to get it as close to new as possible. You can use a .308 small base for the BR stuff.

Just some ideas.

I believe my barrel is torqued to 80 foot pounds and all of my brass has been fired from one rifle I bought it all new with each barrel when they were new.A couple questions that may sound weird, I'm just brainstorming.

What torque value are you putting on the barrel?

Has your brass been fired through multiple chambers?

If you don't know your torque value, that my be the issue use 75-80 foot pounds.

If your brass has been through multiple barrels, run it all through a small base die to get it as close to new as possible. You can use a .308 small base for the BR stuff.

Just some ideas.

So it extracts correctly with the magazine removed?

Try single loading/firing a few minus the magazine and see what happens.

It could be fat brass, but the only thing you've said that doesn't cause it is removing the magazine.......

Is your magazine pressing up on the bottom of the bolt and causing it to tip upwards an excessive amount after firing?

This would explain how pushing on the back of the bolt allows the extractor to grab the rim and remove it.

It would also explain how removing the magazine prevents it from happening.

If indeed it is the cause, then remove your bottom metal and shim it with washers enough to stop the issue or have new pillars installed if you actually have pillars in your stock.

Try single loading/firing a few minus the magazine and see what happens.

It could be fat brass, but the only thing you've said that doesn't cause it is removing the magazine.......

Is your magazine pressing up on the bottom of the bolt and causing it to tip upwards an excessive amount after firing?

This would explain how pushing on the back of the bolt allows the extractor to grab the rim and remove it.

It would also explain how removing the magazine prevents it from happening.

If indeed it is the cause, then remove your bottom metal and shim it with washers enough to stop the issue or have new pillars installed if you actually have pillars in your stock.

Ok, cool.I believe my barrel is torqued to 80 foot pounds and all of my brass has been fired from one rifle I bought it all new with each barrel when they were new.

Use your dial calipers to measure the inside diameter of your bolt face and compare it to average diameter of your case rim diameters. There should be significant clearance. If the bolt face's diameter is slightly undersized it could account for you having the push forward on the back of the bolt.

Zermatt being out of tolerance is not common but everyone has a lemon slip through once in awhile.

Use your dial calipers to measure the inside diameter of your bolt face and compare it to average diameter of your case rim diameters. There should be significant clearance. If the bolt face's diameter is slightly undersized it could account for you having the push forward on the back of the bolt.

I was able to check both the bolt face and rim size there is about 0.001 difference in size if I’m measuring correctly. The bolt head being the bigger one.Zermatt being out of tolerance is not common but everyone has a lemon slip through once in awhile.

I'm not sure if that is an issue for you but that seems tight. (no reference to judge that by)Use your dial calipers to measure the inside diameter of your bolt face and compare it to average diameter of your case rim diameters. There should be significant clearance. If the bolt face's diameter is slightly undersized it could account for you having the push forward on the back of the bolt.

I was able to check both the bolt face and rim size there is about 0.001 difference in size if I’m measuring correctly. The bolt head being the bigger one.

Correction there is about 0.018 difference the bolt head being that larger one.Also, push your extractor outwards until it lines up with your bolt face.

Make sure the contour matches your bolt.

A PPC/Grendel/Valkyrie extractor will look correct until it's lined up.

Also something note worthy is today I did a little load testing to fine tune my load for an upcoming match. It was warmer than normal but I didn’t have any issues with extraction all though I notice my loads were on the hotter side by looking at the primers even though I’m at the minimum for pressure accord to Hodgdons.

Remember, it's CRF, not a push feed, so the diameter of the bolt face doesn't have to be as large as say a Rem or a Savage.

The case rim slips under the edge to some degree to allow controlled feed.

For ejection, it doesn't need much clearance.

The case rim slips under the edge to some degree to allow controlled feed.

For ejection, it doesn't need much clearance.

That sounds better.Correction there is about 0.018 difference the bolt head being that larger one.

Also something note worthy is today I did a little load testing to fine tune my load for an upcoming match. It was warmer than normal but I didn’t have any issues with extraction all though I notice my loads were on the hotter side by looking at the primers even though I’m at the minimum for pressure accord to Hodgdons.

If your cases aren't sized properly to your chamber, meaning too much shoulder setback, it will flatten your primers because it gets a running start rearward and slams the case head against the bolt face.

Do you also get the shiny line from the ejector slot with pretty much any load?

Two of my buddies have Origins and they always have that shiny line no matter what they are shooting.

Two of my buddies have Origins and they always have that shiny line no matter what they are shooting.

I’ll recheck my shoulder bump tomorrow, I usually run 0.0015 to 0.002 setback.If your cases aren't sized properly to your chamber, meaning too much shoulder setback, it will flatten your primers because it gets a running start rearward and slams the case head against the bolt face.

Yes I always have gotten one regardless of any load I’ve tried.Do you also get the shiny line from the ejector slot with pretty much any load?

Two of my buddies have Origins and they always have that shiny line no matter what they are shooting.

When you performed the head space check did you take the extractor out of the bolt?

why would you do that?When you performed the head space check did you take the extractor out of the bolt?

slip the gauge in the extractor

if he put the gauge in front of the extractor (assuming barrel nut prefit) he'd have REAL fucked up brass. if it was shouldered it would never work

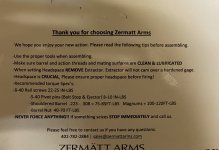

It says to take the extractor out before performing head space. There was a card in the box with my TL3.why would you do that?

slip the gauge in the extractor

if he put the gauge in front of the extractor (assuming barrel nut prefit) he'd have REAL fucked up brass. if it was shouldered it would never work

I was not doing it and had multiple extraction issues. Started taking it out and it stopped.

It if you slip it under then it doesn’t matter because it doesn’t have to slide under.It says to take the extractor out before performing head space. There was a card in the box with my TL3.

I was not doing it and had multiple extraction issues. Started taking it out and it stopped.

Bolt face to shoulder datum is what matters, if it fails outside of that it seems like an extractor tolerance issue.

read that direction again. but slowly.Got it.

OP, good luck locating the problem.

moron

Last edited:

Got it.

OP, good luck locating the problem.

My apologies your 5,422 posts make you an expert.read that direction gain. but slowly.

moron

yeah. i dont headspace barrels with the gauge in front of the extractor of a CRF action and then wonder why i have extraction issues and the necks of my brass look like a fireformed dasherMy apologies your 5,422 post make you an expert.

but i didnt need 5421 posts to know that. cause i can read and comprehend simple instructions

It doesn’t cam over. Therefore slipping it under eliminates the conflict.My apologies your 5,422 post make you an expert.

I also don’t put the head space gauge in front of the extractor…. That’s idiotic.

Read the directions, again slowly, moron… it’s simple.

The word REMOVE is capitalized and bolded. I wonder why? Eh, whatever, it’s just a suggestion anyways.

Read the directions, again slowly, moron… it’s simple.

The word REMOVE is capitalized and bolded. I wonder why? Eh, whatever, it’s just a suggestion anyways.

bold and capitalized cause of people like youI also don’t put the head space gauge in front of the extractor…. That’s idiotic.

Read the directions, again slowly, moron… it’s simple.

The word REMOVE is capitalized and bolded. I wonder why? Eh, whatever, it’s just a suggestion anyways.

bold and capitalized cause of people like you

I highly suggest you do some self reflection…

Slide your go gauge under the extractor. See how it still has wiggle room fore and aft? That’s all that needs to be done to headspace a barrel.I also don’t put the head space gauge in front of the extractor…. That’s idiotic.

Read the directions, again slowly, moron… it’s simple.

The word REMOVE is capitalized and bolded. I wonder why? Eh, whatever, it’s just a suggestion anyways.

Removing just makes it idiot proof. For idiots that don’t realize.