Wasn't disagreeing with you.Only a retard would want to breath in vaporized Teflon but you do you. Hope you have great healthcare.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bolt carrier for precision AR-15

- Thread starter Lone star Shooter

- Start date

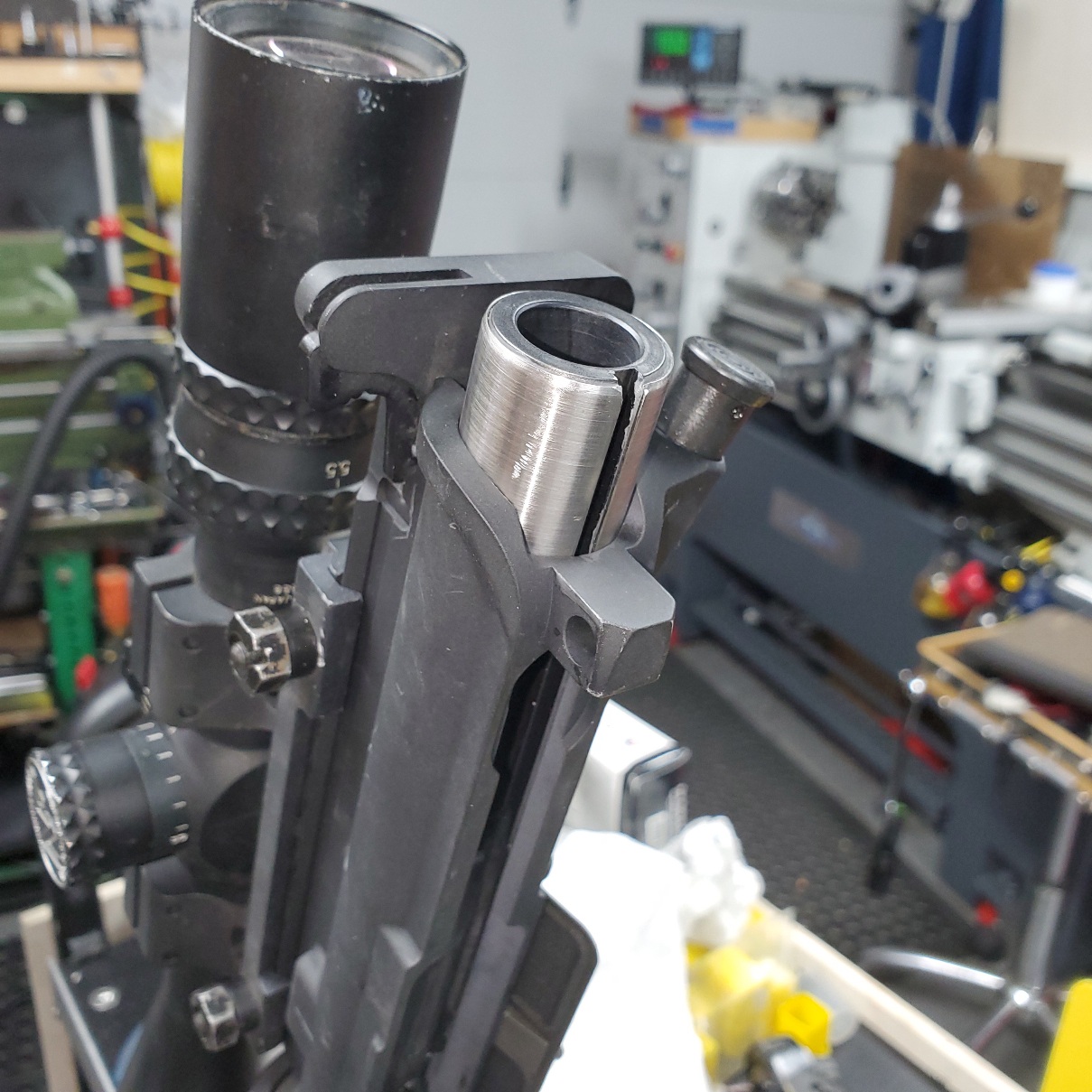

Figured I'd share some photos as well.

I have not seen too many talk about Geissele's "nano coating" yet, but the entire carrier has it, as opposed to the DLC offered only on the bolt for JP.

The machine work is definitely nicer on the JP FMOS, but its also double the price.

As it stands, this rifle now has a frankencombo (JP Bolt and Geissele Carrier).

I have not seen too many talk about Geissele's "nano coating" yet, but the entire carrier has it, as opposed to the DLC offered only on the bolt for JP.

The machine work is definitely nicer on the JP FMOS, but its also double the price.

As it stands, this rifle now has a frankencombo (JP Bolt and Geissele Carrier).

I was set up with dealer terms for almost two decades with Young Mfg. When the new ownership took over, they would neither answer my emails or phone calls. After multiple attempts to contact them, I gave up and rolled over to JP as my #1 go-to choice. By that time, JP was DLC coating their bolts, saving me that often frustrating step dealing with Ionbond, so the switch was a double-win for me. JP customer service has been absolutely top shelf for me, and I'm just small potatoes for an outfit that big.

I've purchased several of the current Young Mfg. M16 bolt carrier groups through my big distributor, RSR, and they've proven to be a very good value.

I haven't tried the Y/M bolts with "HM Defense Bolt Technology". It does look very interesting. But, I'm using top shelf bolts already, bolts of a quality that very seldom if ever fail (one known failure in the last ten years - an LMT with 5000 rounds on it about six years ago). So, I am quite happy to continue using what works so well for me, JP DLC coated bolts.

Besides, 50% or so of the customs I do are in a caliber that requires something besides a standard 5.56 bolt. JP has me well covered there, too, with 6.8 SPC and 6.5 Grendel bolts already DLC coated.

I've purchased several of the current Young Mfg. M16 bolt carrier groups through my big distributor, RSR, and they've proven to be a very good value.

I haven't tried the Y/M bolts with "HM Defense Bolt Technology". It does look very interesting. But, I'm using top shelf bolts already, bolts of a quality that very seldom if ever fail (one known failure in the last ten years - an LMT with 5000 rounds on it about six years ago). So, I am quite happy to continue using what works so well for me, JP DLC coated bolts.

Besides, 50% or so of the customs I do are in a caliber that requires something besides a standard 5.56 bolt. JP has me well covered there, too, with 6.8 SPC and 6.5 Grendel bolts already DLC coated.

Evidentially you're either extremely ignorant or run your gas guns 2K Deg. F.Thats great, so as it burns/vaporized you breath in a known carcinogen. YAY for Cancer!

For the uniformed among us : Given that PTFE degrades above 350 ºC (662 ºF) which is well beyond any oil based lubes smoking vaporization point . I wonder how long and # of rounds down bore ,for a BCG to reach 662 Deg. F.

Last edited:

Not sure where you're getting that the small frame JP carrier & bolt are double the price of the Geiselle, but JP's website lists is as #375 vs Geiselle at $325.I have not seen too many talk about Geissele's "nano coating" yet, but the entire carrier has it, as opposed to the DLC offered only on the bolt for JP.

The machine work is definitely nicer on the JP FMOS, but its also double the price.

JP FMOS Small Frame BCG

And while all Geiselle's stuff is always good, their "nano" coating is CrN which is a PVD applied coating.

CrN is not as hard as DLC nor does it have as low of a COF as the DLC, so I'll take the DLC every day, all day...................& I deal with both on a commercial basis in the auto industry.

But the Geiselle does use an improved version of C-158 for the bolt; but even though there is a lot of variability of 9310 in the marketplace, I have confidence in JP's QA to control what they are using.

And again, on the bolt, DLC is preferred over CrN.................& the JP bolts are the best I've ever used with regard to being easy to clean & I've never heard of one breaking, much less have one break myself.

As to the carriers, I have DLC carriers & they are very, very slick & smooth in the upper; even the polished, uncoated SS steel LMOS carrier that JP makes is very very slick & hard to tell the difference between it & DLC. And, though uncoated, if well lubed, I surely don't expect it to wear out in any reasonable time frame.

MM

More or less where I've ended up with Young Mfg. as well, though I never had dealer status. Too bad they've changed business practices.I was set up with dealer terms for almost two decades with Young Mfg. When the new ownership took over, they would neither answer my emails or phone calls. After multiple attempts to contact them, I gave up and rolled over to JP as my #1 go-to choice. By that time, JP was DLC coating their bolts, saving me that often frustrating step dealing with Ionbond, so the switch was a double-win for me. JP customer service has been absolutely top shelf for me, and I'm just small potatoes for an outfit that big.

I've purchased several of the current Young Mfg. M16 bolt carrier groups through my big distributor, RSR, and they've proven to be a very good value.

I haven't tried the Y/M bolts with "HM Defense Bolt Technology". It does look very interesting. But, I'm using top shelf bolts already, bolts of a quality that very seldom if ever fail (one known failure in the last ten years - an LMT with 5000 rounds on it about six years ago). So, I am quite happy to continue using what works so well for me, JP DLC coated bolts.

I've used a couple of their version of the HMB bolt design, but they've not been run anywhere near enough to say if they last longer than a standard design. Those are also available direct from HMB Defense as well.

I used quite a few of Y/M's lightweight carriers, but it appears that they've discontinued them now as well.

JP's stuff is all top notch & they charge for it too, but it works & works very well. If I could put their carriers & bolts into everything, I would.

All the RCA stuff is also way better than good as well & have never had an issue with anything from them. I don't think that anyone does nitriding better than RCA.

MM

The Ultimate BCG coating would be BAM aka AlMgB14. Diamond hardness with 1/2 the friction coefficient of Teflon .

These BAM materials are showing exceptionally

promising wear resistance, superior to that of commercially available hard materials, including

polycrystalline diamond!

https://www1.eere.energy.gov/manufacturing/industries_technologies/imf/pdfs/bammaterialsjan05.pdf

What’s almost as hard as diamond, slicker than Teflon and “green” enough to reduce the United States’ industrial energy consumption by trillions of BTUs a year? The answer is BAM – a ceramic alloy created by combining a mix of boron, aluminum and magnesium with titanium diboride. The world’s third hardest material, next to diamond and cubic boron nitride, BAM is as slippery as it is strong. With a 0.02 coefficient of friction, it is substantially slicker than Teflon (0.05) and lubricated steel (0.16).

These BAM materials are showing exceptionally

promising wear resistance, superior to that of commercially available hard materials, including

polycrystalline diamond!

https://www1.eere.energy.gov/manufacturing/industries_technologies/imf/pdfs/bammaterialsjan05.pdf

What’s almost as hard as diamond, slicker than Teflon and “green” enough to reduce the United States’ industrial energy consumption by trillions of BTUs a year? The answer is BAM – a ceramic alloy created by combining a mix of boron, aluminum and magnesium with titanium diboride. The world’s third hardest material, next to diamond and cubic boron nitride, BAM is as slippery as it is strong. With a 0.02 coefficient of friction, it is substantially slicker than Teflon (0.05) and lubricated steel (0.16).

Time to build a 400 LegendI'm the dork who paid full price for an LMT 6.8 BCG mistakenly thinking it would work with a 6ARC

View attachment 8395178

Do you wildcat any? There are some cool receiver sets you can use that take Six8 PMAGs, from New Frontier Armory.I'm the dork who paid full price for an LMT 6.8 BCG mistakenly thinking it would work with a 6ARC

View attachment 8395178

Mag well is a bit larger in length and width.

You missed a pretty critical detail in both my post and the photos.Not sure where you're getting that the small frame JP carrier & bolt are double the price of the Geiselle, but JP's website lists is as #375 vs Geiselle at $325.

JP FMOS Small Frame BCG

And while all Geiselle's stuff is always good, their "nano" coating is CrN which is a PVD applied coating.

CrN is not as hard as DLC nor does it have as low of a COF as the DLC, so I'll take the DLC every day, all day...................& I deal with both on a commercial basis in the auto industry.

But the Geiselle does use an improved version of C-158 for the bolt; but even though there is a lot of variability of 9310 in the marketplace, I have confidence in JP's QA to control what they are using.

And again, on the bolt, DLC is preferred over CrN.................& the JP bolts are the best I've ever used with regard to being easy to clean & I've never heard of one breaking, much less have one break myself.

As to the carriers, I have DLC carriers & they are very, very slick & smooth in the upper; even the polished, uncoated SS steel LMOS carrier that JP makes is very very slick & hard to tell the difference between it & DLC. And, though uncoated, if well lubed, I surely don't expect it to wear out in any reasonable time frame.

MM

I was comparing the cost of bolt carriers, not the entire complete BCG with bolt.

A JP Full Mass bolt carrier is in fact double the price of the Geissele Enhanced bolt carrier.

Also, multiple others in this thread have pointed out that JP’s actual carrier is NOT dlc, so that would be a moot point.

I just try to keep it simple, so I just drop in JP FMOS BCGs, just like I only use Bartlein barrels.

Yes, I misunderstood that you were only referring to the carriers..........but the JP is not quite double the cost for the Geiselle, but close enough.You missed a pretty critical detail in both my post and the photos.

I was comparing the cost of bolt carriers, not the entire complete BCG with bolt.

A JP Full Mass bolt carrier is in fact double the price of the Geissele Enhanced bolt carrier.

Also, multiple others in this thread have pointed out that JP’s actual carrier is NOT dlc, so that would be a moot point.

And yes, I know full well that none of the carriers from JP are DLC. Nonetheless, they are still, very, very slick.

For a carrier of the Geiselle's quality, & PVD coated, the price is not bad & the difference between a PVD & a DLC carrier matters less that it does on the bolt where DLC's toughness is still an edge over CrN via PVD.

And a lot still depends on the quality of the sources doing the coatings. But I have no doubt that Geiselle is using a high quality source.

MM

I cannot complain about it, for the price. With the brownells discount, it was $100+tax&shipping.Yes, I misunderstood that you were only referring to the carriers..........but the JP is not quite double the cost for the Geiselle, but close enough.

And yes, I know full well that none of the carriers from JP are DLC. Nonetheless, they are still, very, very slick.

For a carrier of the Geiselle's quality, & PVD coated, the price is not bad & the difference between a PVD & a DLC carrier matters less that it does on the bolt where DLC's toughness is still an edge over CrN via PVD.

And a lot still depends on the quality of the sources doing the coatings. But I have no doubt that Geiselle is using a high quality source.

MM

Comparatively though, there is a big difference between this and the JP FMOS, in reliable operation, and thats where it mattered to me most.

The JP carrier, required their proprietary 1 piece gas key to run reliably.

The Geissele one will accept the bolt with either the JP 1 piece gas key, or the milspec 3 piece.

When I watched the SOTAR gauging video of the Geissele carrier, he specifically noted when gauging the internal diameter and the area for the gas rings as very tight (ideal for a match rifle) and ensuring a more sealed gas operation (with less gas leaking)..Im paraphrasing so I could be butchering that.

Similarly watching the JP gauging video, the JP carrier was looser in this tolerance. One of the items mentioned in that same video was that if you were having issues with the JP Bolt running reliably, ditch their 1 piece gas rings, for a milspec 3 piece set. I had that exact issue previously.

That's interesting about the bore ID for the gas rings.

I have a couple of the JP LMOS carriers but I changed the 1 PC rings with a standard 3 PC on the JP bolt...........never even attempted to use the 1 PC. Just didn't like the way the 1 PC felt.

No problems with the 2 I have. Both were bought as carriers only & one has a JP bolt in it, the other has a Y/M bolt as I recall.

Never measured the bore on any of the carriers.

But, yes, better gas ring sealing is never a bad thing.

I have a couple of the JP LMOS carriers but I changed the 1 PC rings with a standard 3 PC on the JP bolt...........never even attempted to use the 1 PC. Just didn't like the way the 1 PC felt.

No problems with the 2 I have. Both were bought as carriers only & one has a JP bolt in it, the other has a Y/M bolt as I recall.

Never measured the bore on any of the carriers.

But, yes, better gas ring sealing is never a bad thing.

Been using the box stick JP FMOS bcg for A while in 4 ARs ( yeah small sample size, started late and can’t buy more as I live in Wa) with no issues. These are accuracy oriented rifles . Maybe just lucky, but I like them.

I'd really like for someone to do a modern comparison of the "flared tail" style carriers, to see if they have any actual impact on accuracy.

I source the bolt carrier and bolt separately.

I buy the JP bolt kit that includes the firing and cam pins. These are DLC coated. I do replace their single gas ring and extractor spring and insert/donut with Springco replacements. I headspace this to the barrels as needed. Finally I'll place it in either one of my few remaining Young's National Match carriers or a Lantec Enhanced carrier. Both are of the "enhanced" variety for a more consistent lockup.

I take the same route for my .224v Valkyries as well.

Overall a quality hard chrome is my finish of choice. NiB is okay if done right and Lantec does it right. DLC is my second choice.

I buy the JP bolt kit that includes the firing and cam pins. These are DLC coated. I do replace their single gas ring and extractor spring and insert/donut with Springco replacements. I headspace this to the barrels as needed. Finally I'll place it in either one of my few remaining Young's National Match carriers or a Lantec Enhanced carrier. Both are of the "enhanced" variety for a more consistent lockup.

I take the same route for my .224v Valkyries as well.

Overall a quality hard chrome is my finish of choice. NiB is okay if done right and Lantec does it right. DLC is my second choice.

I would like to see that as well. I can't help but wonder if the average guy wouldn't notice inside of 200yds, but "might" see it past that.I'd really like for someone to do a modern comparison of the "flared tail" style carriers, to see if they have any actual impact on accuracy.

Where was that indoor warehouse that was super long ... ( eliminated wind drift ) when you need it... Lol

Still waiting on quotes back to build mine here. I guess contractors are just too busyI would like to see that as well. I can't help but wonder if the average guy wouldn't notice inside of 200yds, but "might" see it past that.

Where was that indoor warehouse that was super long ... ( eliminated wind drift ) when you need it... Lol

Someone above reminded me about Lantac..and it is a carrier that I do have. I guess I'll do my own testing next time I go shoot, throw the JP bolt into the lantac enhanced carrier, and see if the groups change at all.

My sample size of 1 is good enough for me, if Im testing for my own money's worth LOL.

I got my lantac enhanced years ago. Saw the price at a store appropriate for their standard model, but clearly the enhanced product..so I jumped on it, and forgot about it ever since.

Any chance we could get a list of oversized bolt carriers to prevent carrier tilt? Young National Match seems to be old news since they sold to a different holding company. I had been thinking of buying a JP - are they considered oversized?

Not sure but I have sort of standardized on the JP enhanced FMOS. My next precision AR upper ( 22” heavy Bartlein, JP CTR2 upper, enhanced FMOS BCG and 15”mk3 hand guard) is being built as you read this by Craddock.

I have been using my own enhanced BCG for years. Fitted sleeve, JB Welded, then slot cut. Due to oversized tail, the buffer tubes are bored and polished. The old brake cylinder hone in the tailstock does a good in polishing the bored out tube.

The one with pressed in brass plug is the same on all my service rifles. I've done a few for friends, all were happy with them. No functionality issues.

It must have been close to 10 years ago when I did the first one. It was on a new service rifle upper build, so I did not have A-B comparison. At 200 yards, if I remember, I shot five, 5 shot groups at 200 at different days, none went over 0.8 inch.

Fast forward to before the plandemic, I loaned my rifle to a friend along with my ammo to shoot on a 2-day mid range at Bayou Rifles in Houston area. With 4.5x power scope, 20 inch service rifle, prone, sling, he posted 1189-62X, launching 80 VLDs. The bolt gun with optics sling shooter who won the sling category, I believe was using a 6mm cartridge, shot 1191-59X, maybe 1192. Shooters are both HM.

One data point, but it illustrates the fully captured BCG did not hurt precision, maybe it helped. The shooter to his credit, shot the system very accurately.

The one with pressed in brass plug is the same on all my service rifles. I've done a few for friends, all were happy with them. No functionality issues.

It must have been close to 10 years ago when I did the first one. It was on a new service rifle upper build, so I did not have A-B comparison. At 200 yards, if I remember, I shot five, 5 shot groups at 200 at different days, none went over 0.8 inch.

Fast forward to before the plandemic, I loaned my rifle to a friend along with my ammo to shoot on a 2-day mid range at Bayou Rifles in Houston area. With 4.5x power scope, 20 inch service rifle, prone, sling, he posted 1189-62X, launching 80 VLDs. The bolt gun with optics sling shooter who won the sling category, I believe was using a 6mm cartridge, shot 1191-59X, maybe 1192. Shooters are both HM.

One data point, but it illustrates the fully captured BCG did not hurt precision, maybe it helped. The shooter to his credit, shot the system very accurately.

Last edited:

I take it you had to machine the sleeves?I have been using my own enhanced BCG for years. Fitted sleeve, JB Welded, then slot cut. Due to oversized tail, the buffer tubes are bored and polished. The old brake cylinder hone in the tailstock does a good in polishing the bored out tube.

The one with pressed in brass plug is the same on all my service rifles. I've done a few for friends, all were happy with them. No functionality issues.

It must have been close to 10 years ago when I did the first one. It was on a new service rifle upper build, so I did not have A-B comparison. At 200 yards, if I remember, I shot five, 5 shot groups at 200 at different days, none went over 0.8 inch.

Fast forward to before the plandemic, I loaned my rifle to a friend along with my ammo to shoot on a 2-day mid range at Bayou Rifles in Houston area. With 4.5x power scope, 20 inch service rifle, prone, sling, he posted 1189-62X, launching 80 VLDs. The bolt gun with optics sling shooter who won the sling category, I believe was using a 6mm cartridge, shot 1191-59X, maybe 1192. Shooters are both HM.

One data point, but it illustrates the fully captured BCG did not hurt precision, maybe it helped. The shooter to his credit, shot the system very accurately.

View attachment 8424035View attachment 8424036View attachment 8424037View attachment 8424038View attachment 8424047

Yes. Start with with 1 inch SS tube 1/8 or 1/16 wall. Turn down OD to fit, bore ID to accommodate however thick JB you wish to employ.I take it you had to machine the sleeves?

Remove finish and rough up the BCG tail section

On page one of this discussion I posted a list of quite a few of the similar ones most popularly offered:Any chance we could get a list of oversized bolt carriers to prevent carrier tilt? Young National Match seems to be old news since they sold to a different holding company. I had been thinking of buying a JP - are they considered oversized?

Post in thread 'Bolt carrier for precision AR-15'

https://www.snipershide.com/shooting/threads/bolt-carrier-for-precision-ar-15.7042880/post-11518991

What's the final OD? I need to remeasure the Azimuth ones, but I think there like 0.040" lager than standard.

Depends on your comfort zone, 0.001 on each side. Measure ID of upper tailside, turn down sleeve to fit.

The JP is NOT double the price of the Geissele. In fact the Geissele is $10 more. Not sure where you got that info, or bought yours considering your own them bothFigured I'd share some photos as well.

I have not seen too many talk about Geissele's "nano coating" yet, but the entire carrier has it, as opposed to the DLC offered only on the bolt for JP.

The machine work is definitely nicer on the JP FMOS, but its also double the price.

As it stands, this rifle now has a frankencombo (JP Bolt and Geissele Carrier).

The JP is $375

The Geissele is $385

He was referring to just the bolt carrier, which $145 versus $245. Your pricing is for the complete carrier groups.The JP is NOT double the price of the Geissele. In fact the Geissele is $10 more. Not sure where you got that info, or bought yours considering your own them both

The JP is $375

The Geissele is $385

I was reading through this and just as I was thinking (what I wrote in 2020) the next post is from me in 20 fucking 20 saying my same thought.Did you necro-thread this 4 year old discussion just to shill your barrel maker...?

For a barrel that you've admitted you havent even shot yet, at that.

Jeez I must be getting old. Already forgetting shit. Well, at least I’m consistent and still stand by my post

He’s the 2nd one in this thread to miss that point and jump to my “error” in price comparison.He was referring to just the bolt carrier, which $145 versus $245. Your pricing is for the complete carrier groups.

People are quicker to jump to correct someone else than they are to even see if they read correctly in the first place.

Last edited:

Young National Match if you can find them

I've settled on the Lantac E-BCG

I've settled on the Lantac E-BCG

“Icon defense BCG have me intrigued.

This carrier is not compatible with mil-spec bolts.*”

I’m still intrigued, even with a proprietary bolt.“

This carrier is not compatible with mil-spec bolts.*”

Edit: I typically run JP BCG and HP bolts, never been one to mix and match.

Young's website is back up & running. Not sure who is running the business now though.Young National Match if you can find them

MM

KE ArmsYoung's website is back up & running. Not sure who is running the business now though.

MM

I could not say whether a "larger" bolt carrier makes a difference in accuracy but I use the fatties in everything I build. Preferably a YM National Match but have 4 or 5 JP FMOS carriers and a Lantac or 2.

I am not 100% positive, but I also have a Les Baer 6.5 Grendel and his carrier is either a YM NM carrier or copied one exactly.

I wish I could get the YM NM carriers still.

I am not 100% positive, but I also have a Les Baer 6.5 Grendel and his carrier is either a YM NM carrier or copied one exactly.

I wish I could get the YM NM carriers still.

I’ve had 5 JP FMOS complete BCG’s for 5 22ARC builds that have been back ordered for going on 4 months, and have just shipped earlier this week. Not sure what the source of delay, whether it’s military demand for 6ARC, or overall demand for the common bolt face cartridges. Love me some JP gear, but still have to change gas rings to get proper gas function.

Similar threads

- Replies

- 81

- Views

- 3K

- Replies

- 91

- Views

- 4K

- Replies

- 1

- Views

- 282