I have never encountered this - My bolt would not close on two of the rounds from a factory box. All other 18 rounds were fine.

Rifle is Sako 85 Finnlight

Ammo is Winchester Silvertip 300 WSM 150 gr.

I have shot nothing but this ammo, about 300 rounds in the last five years.

What can cause this? I’m

I registered on snipershide just now so that I could respond to this topic... (long time listener, first time caller yadi yadi)

I hope it's ok to comment on an old thread.

Today, I was going through all of my old(er) inventory and thought I'd dig a little deeper into an issue I had with some cartridges in a box of Winchester Ballistic Silvertip 150 gr ammo for 300 WSM I'd marked "DO NOT USE! 4 cartridges will not chamber in either of my 300 WSM rifles"

I wondered if anybody else had the same experience as I had with this ammo. Google hit on this very SH thread.

I've put perhaps a half dozen boxes of this factory ammo thru my 2 300 WSM's (both stock, off-the-shelf rifles). I had attempted to reach out to Winchester Ammunition on 3 separate occasions over the years to see what their response would be about such failures with this ammo. Never heard back.

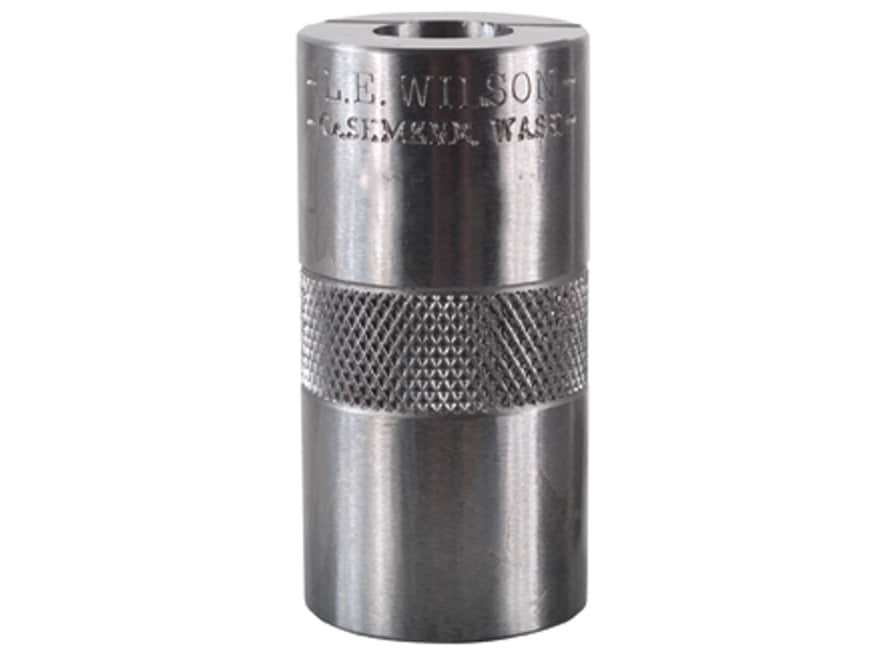

Anyway, today after I verified that the 4 cartridges wouldn't chamber in either of my 300 WSM rifles, that the bolt wouldn't close, I measured them with my Hornady headspace comparator using the E420 insert. WOW! The shoulders of these 4 cartridges measure between 3 and 6 thousandths bigger than what the rifles can take (based on fireformed case measurements); between 7 and 10 thousandths bigger than the good factory ammo cartridges. So, yes, they cannot be chambered, the shoulder is not setback far enough to fit the chamber's headspace.

I cannot remember if I was "in the field" (hunting) or at the range when I discovered these bad cartridges. Regardless, these incorrectly sized cases got past Winchester's QA and into my magazine. Not a happy thing.

I now (usually) reload for most of my hunting rifles.

My $.02