I recently purchased a Teslong Borescope and regretfully there is not a library of images on google to compare my barrels to. Please provide any and all feedback on what I am seeing in the below images. I am intentionally leaving out round counts on the barrels to not bias anyone's answers. Thanks in advance for the help and education!

Gunsmithing Borescope Images - Help me identify...

- Thread starter dukerugger25

- Start date

- Tags

- borescope carbon ring teslong

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

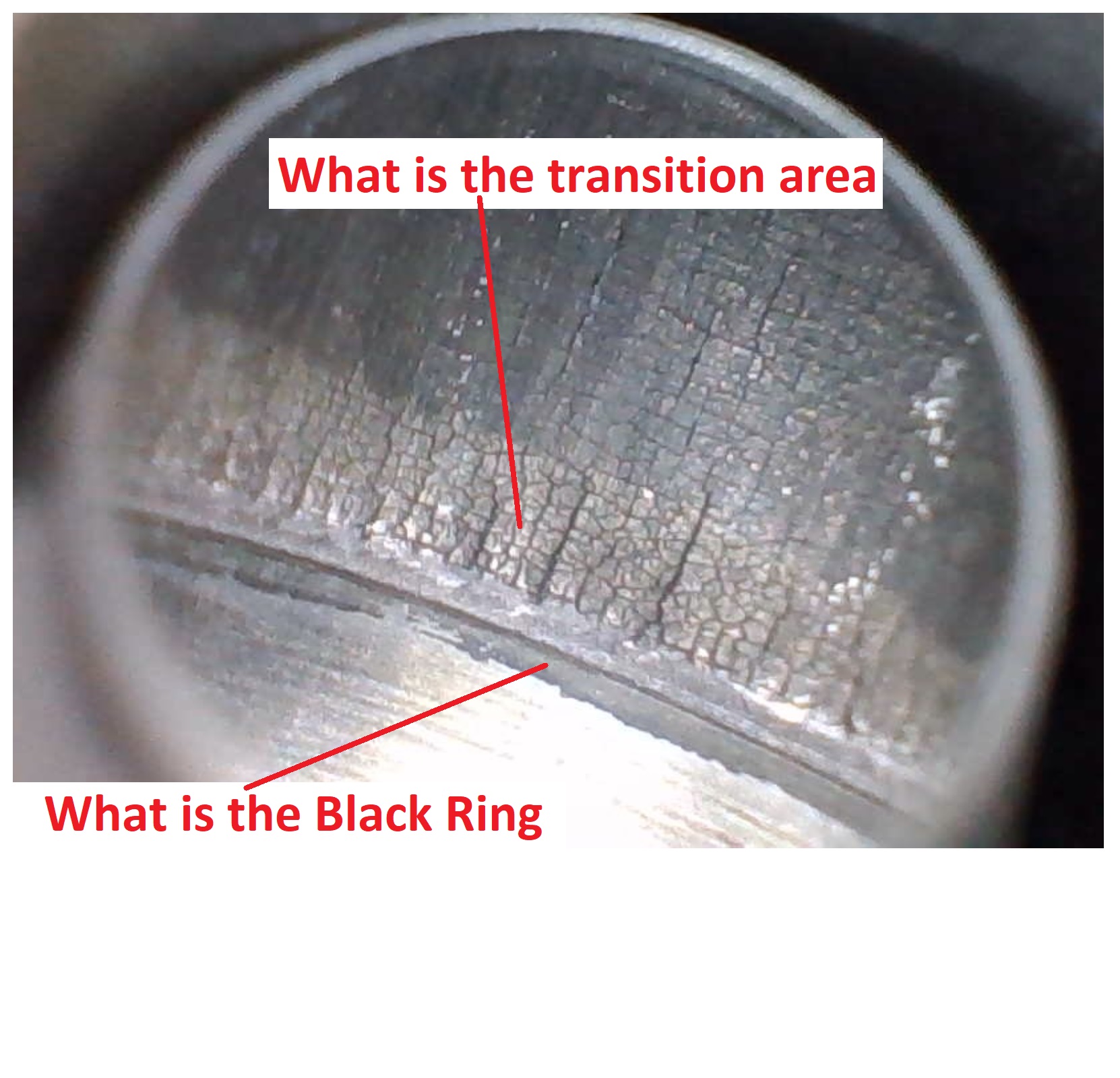

First picture is the transition from the neck of the chamber to the freebore of the chamber. The black carbon is just where your brass ends and where carbon first deposits forward of the cartridge.

The transition area where the carbon is a different color is just where the carbon is super heated by the powder burning out the end of the neck of the brass. Imagine a rocket engine and that is the nozzle. That is part of the barrel/chamber that receives the most heat. It is also where you can be jamming bullets into the carbon if you have enough built up in the freebore area to cause the freebore to be smaller in diameter than the bullet.

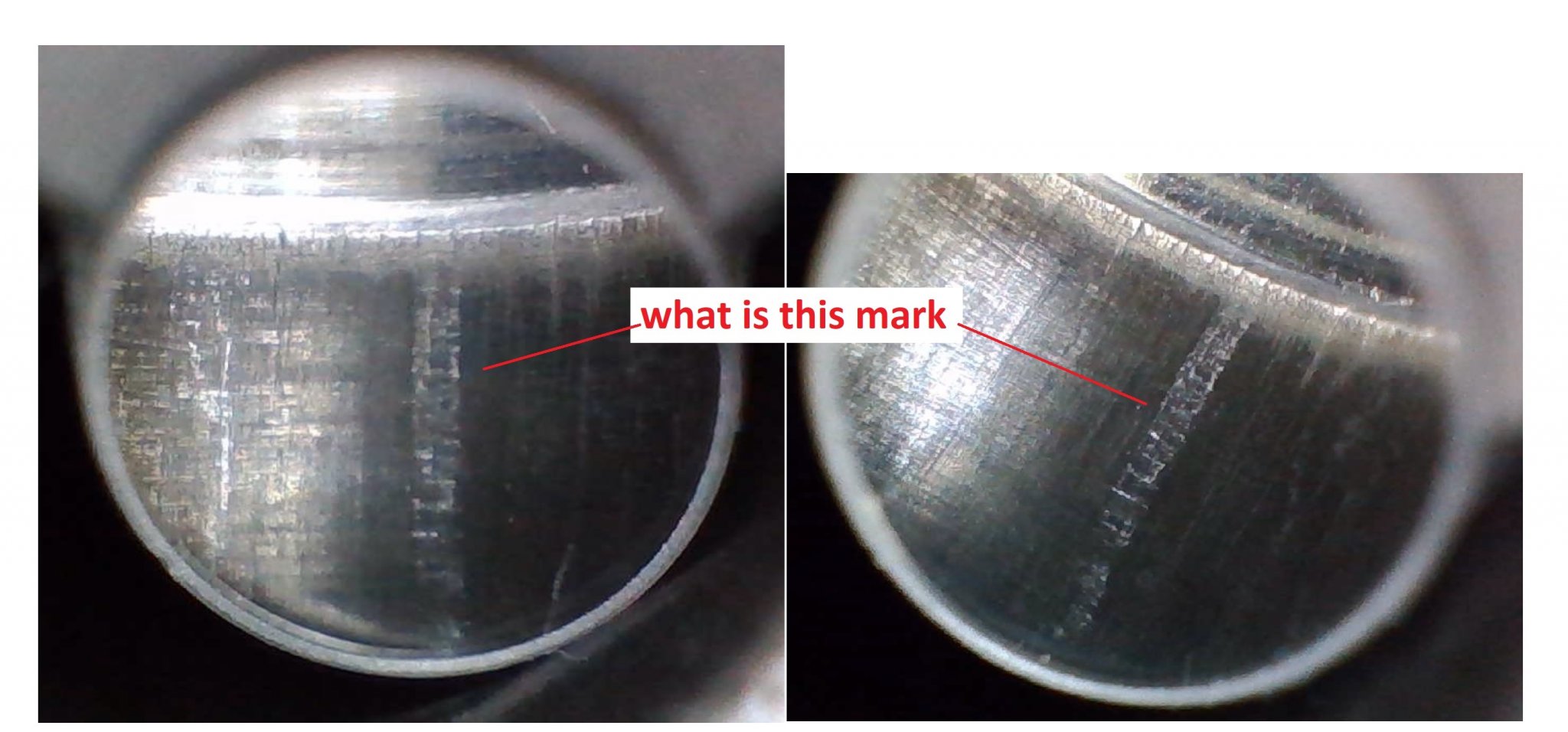

No idea what that Mark is in the second picture. Looks superficial like a rub mark caused by the end of the bore scope as you inserted it into the chamber. That mark would cause me no concern.

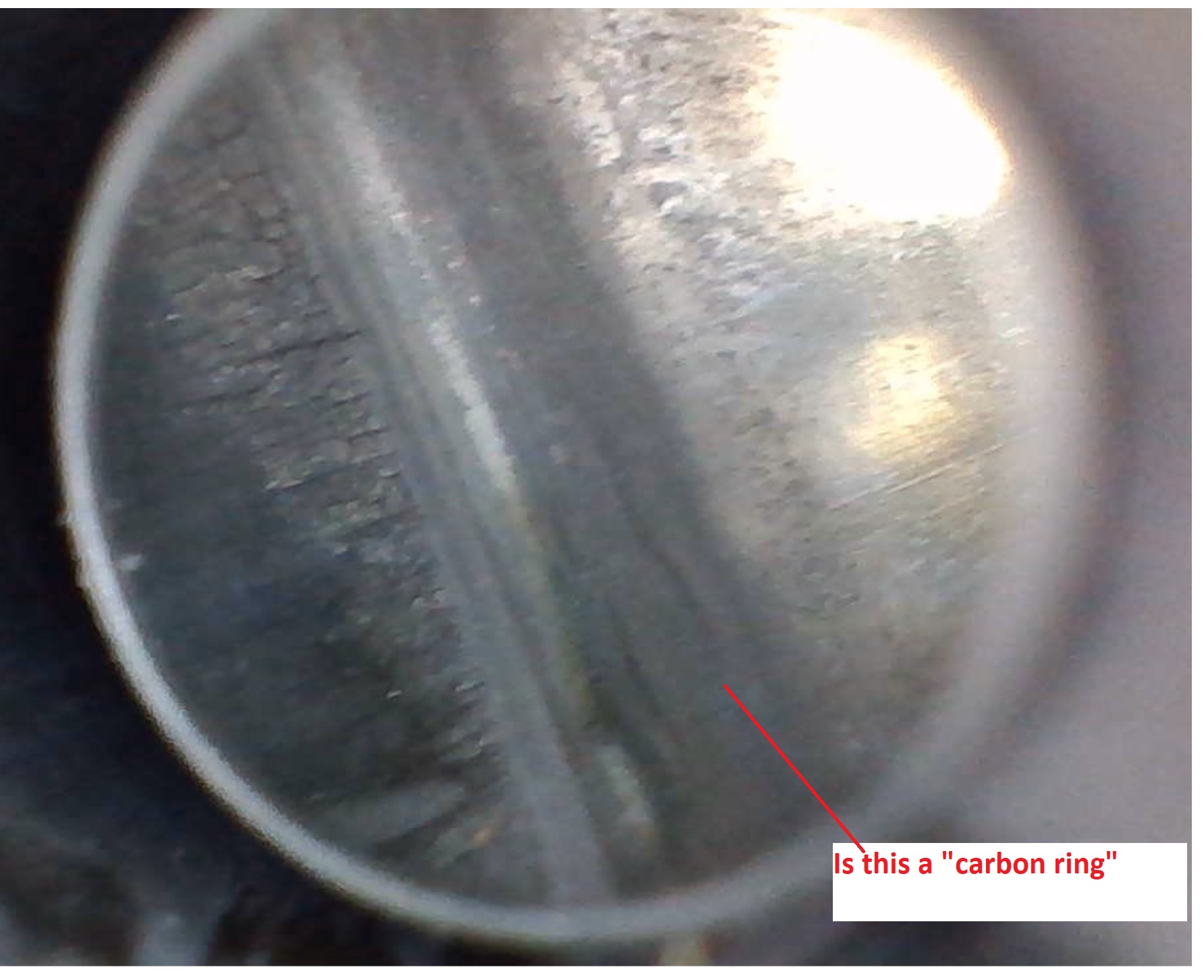

Last picture is not a carbon ring. That is a part of the chamber that is pretty much inconsequential. The brass is trimmed short of that area and carbon there should not interfere with chambering.

If this was a 6.5 Creedmoor I'd guess the round count to be 1500 rounds. Am I in the ballpark?

The transition area where the carbon is a different color is just where the carbon is super heated by the powder burning out the end of the neck of the brass. Imagine a rocket engine and that is the nozzle. That is part of the barrel/chamber that receives the most heat. It is also where you can be jamming bullets into the carbon if you have enough built up in the freebore area to cause the freebore to be smaller in diameter than the bullet.

No idea what that Mark is in the second picture. Looks superficial like a rub mark caused by the end of the bore scope as you inserted it into the chamber. That mark would cause me no concern.

Last picture is not a carbon ring. That is a part of the chamber that is pretty much inconsequential. The brass is trimmed short of that area and carbon there should not interfere with chambering.

If this was a 6.5 Creedmoor I'd guess the round count to be 1500 rounds. Am I in the ballpark?

Bigger question is it shooting??? If so wtf cares shoot it

First picture is the transition from the neck of the chamber to the freebore of the chamber. The black carbon is just where your brass ends and where carbon first deposits forward of the cartridge.

The transition area where the carbon is a different color is just where the carbon is super heated by the powder burning out the end of the neck of the brass. Imagine a rocket engine and that is the nozzle. That is part of the barrel/chamber that receives the most heat. It is also where you can be jamming bullets into the carbon if you have enough built up in the freebore area to cause the freebore to be smaller in diameter than the bullet.

No idea what that Mark is in the second picture. Looks superficial like a rub mark caused by the end of the bore scope as you inserted it into the chamber. That mark would cause me no concern.

Last picture is not a carbon ring. That is a part of the chamber that is pretty much inconsequential. The brass is trimmed short of that area and carbon there should not interfere with chambering.

If this was a 6.5 Creedmoor I'd guess the round count to be 1500 rounds. Am I in the ballpark?

Thank you for the all the info and detail! It is a 300prc with only 120 rounds (100 factory) down the barrel. Doesn't look pretty, which is my concern

Bigger question is it shooting??? If so wtf cares shoot it

It is not shooting, that's the problem. Factory 225 ammo started showing pressure signs and stuck in chamber after 115 rounds. Trying to diagnose what could be going on

It is not shooting, that's the problem. Factory 225 ammo started showing pressure signs and stuck in chamber after 115 rounds. Trying to diagnose what could be going on

I ran into this with my 6.5 saum at a little over 300 rounds. I had a carbon ring similar to yours that caused over pressure conditions and an increase in velocity. I tried several cleaners and soaking it but ended up using iosso bore paste to get it clean.

Thanks @Bradu. Was going to try wipe out but I also have jb bore paste. Never needed it so early in a barrels life though, so hesitant to pull it out yet.

I never had that issue before. I didn't want to use the paste either but I gave up with the other options.

Something isn't right, the throat of your barrel looks like it's nearing end of life of the barrel, there shouldn't be that much fire cracking in 120 rounds. Did you buy the rifle used and the seller said that 120 was the round count??

To be fair, the pictures portion of the barrel is the first portion to show fire cracking, but it is a clearance area in the chamber that fire cracking doesn't matter in. I bet the rifling lead looks pretty good still.

Brand New rifle. I scoped it before ever shooting it, and it was definitely a new barrel.

Anyone else with a 300prc seeing similar results?

May be sending it back to the smith....

Anyone else with a 300prc seeing similar results?

May be sending it back to the smith....

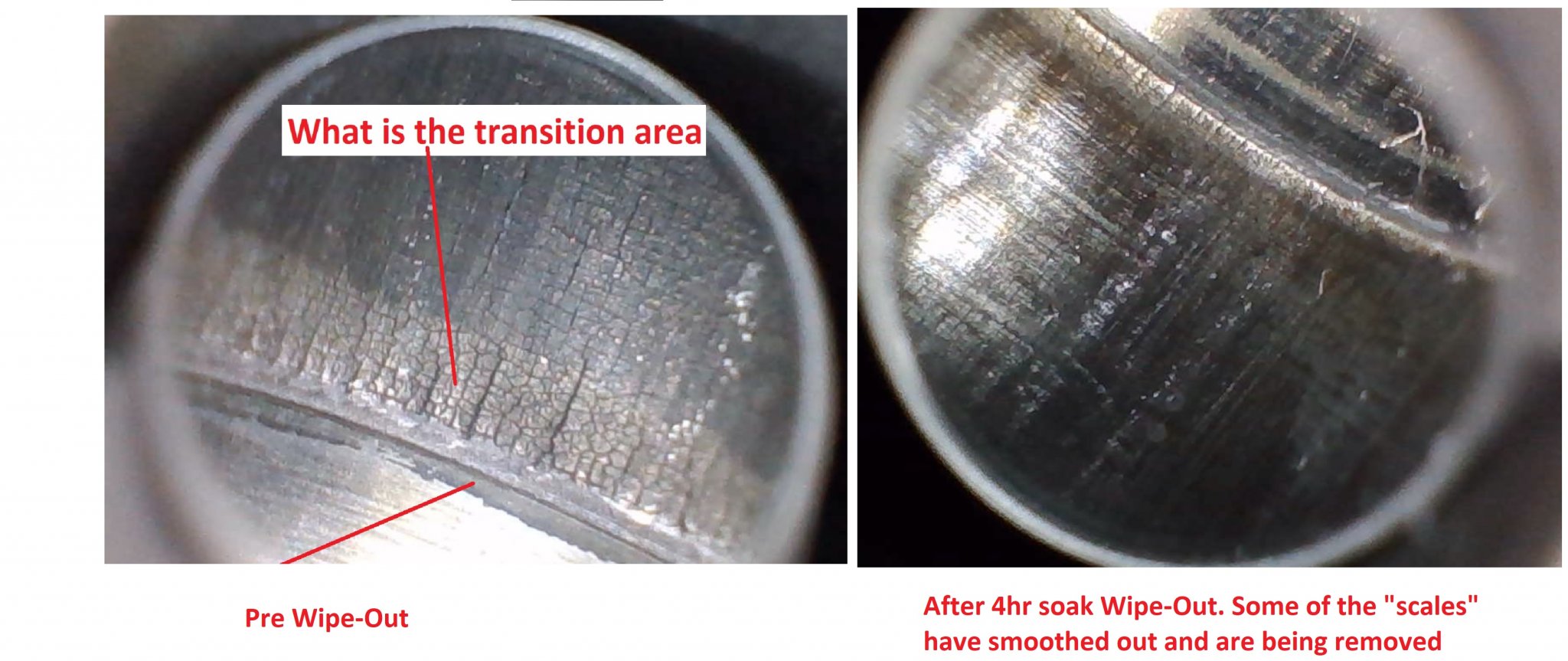

I would clean it with the paste before sending it to the gunsmith. My barrel was very similar looking and after some soaking and a bronze brush, there were small pieces of carbon that came out. Once I switched to the paste, a lot of that cleaned up and the bore looked considerably better. I think a lot of that will clean up and will make it look better.

What powder was this, h1000?

What powder was this, h1000?

Rl26 powder. Thanks for the recommendation to scrub it first. Will do next weekend when back in town.I would clean it with the paste before sending it to the gunsmith. My barrel was very similar looking and after some soaking and a bronze brush, there were small pieces of carbon that came out. Once I switched to the paste, a lot of that cleaned up and the bore looked considerably better. I think a lot of that will clean up and will make it look better.

What powder was this, h1000?

Education maybe?Bigger question is it shooting??? If so wtf cares shoot it

Brand New rifle. I scoped it before ever shooting it, and it was definitely a new barrel.

Anyone else with a 300prc seeing similar results?

May be sending it back to the smith....

What's the smith going to do?

Bore pasteWhat's the smith going to do?

Bore paste

Lol does bore paste restore fire cracking?

Honestly the pictures look fine for a cartridge that's burning +-80 grains of powder in a 30 cal hole. If it's shooting who cares?...barrels are an expendable part of the rifle. If you wanted show rifling you should have put it in the safe as a safe queen.

I have seen fire cracking start to happen in 40 rounds with hot calibers... Guess what they still hammered until they were shot out.

I don't see any odd machining marks that would indicate a bad chamber so if i was the smith I would tell you to shoot it.

Is it grouping though you still haven't said?

He did. He fully answered you?Lol does bore paste restore fire cracking?

Honestly the pictures look fine for a cartridge that's burning +-80 grains of powder in a 30 cal hole. If it's shooting who cares?...barrels are an expendable part of the rifle. If you wanted show rifling you should have put it in the safe as a safe queen.

I have seen fire cracking start to happen in 40 rounds with hot calibers... Guess what they still hammered until they were shot out.

I don't see any odd machining marks that would indicate a bad chamber so if i was the smith I would tell you to shoot it.

Is it grouping though you still haven't said?

Lol does bore paste restore fire cracking?

Honestly the pictures look fine for a cartridge that's burning +-80 grains of powder in a 30 cal hole. If it's shooting who cares?...barrels are an expendable part of the rifle. If you wanted show rifling you should have put it in the safe as a safe queen.

I have seen fire cracking start to happen in 40 rounds with hot calibers... Guess what they still hammered until they were shot out.

I don't see any odd machining marks that would indicate a bad chamber so if i was the smith I would tell you to shoot it.

Is it grouping though you still haven't said?

He stated he has started having issues with pressure in factory rounds and said something about stuck in the chamber, I'm assuming that he may have had the bullet stick in the throat when removing a loaded round. So it doesn't matter if it shoots or not if a carbon ring is causing problems.

He did. He fully answered you?

Missed his reply in my notifications.

Op when you say stuck in the chamber are you talking heavy bolt lift?

Last edited:

I'm sure if he chambers a round that there will be rub marks on the ogive of the bullet. I wish I had pictures of the before and after on my barrel because with the round count he is saying, the barrel isn't as bad as some of you think it is.

Thanks to all for the replies.

It was shooting 0.5-0.8" @ 200yds for the first 100 rounds. The last 20 were closer to 3-4" groups.

The spent case was sticking in the chamber, not the bullet. Also large ejector swipe and flat primers for the last 20 rounds.

It was shooting 0.5-0.8" @ 200yds for the first 100 rounds. The last 20 were closer to 3-4" groups.

The spent case was sticking in the chamber, not the bullet. Also large ejector swipe and flat primers for the last 20 rounds.

I stripped it today and cleaned with BT C4. Helped a bit, but not a ton. Had to order some fresh paste. when I use jb bore paste, what size brass brush should I use, regular 0.308 or oversized to a 0.338?

I soaked mine with c4 for 48 hours and it did very little to remove it. I would use the 308 brush and wrap a patch around the bristles. I used short strokes in the throat area. You will need to change the patch a few times. See how that works, you may have to step up to a bigger brush.

Sweet! Will post after jb'ing it

Actually sounds like an ammo related problem to me. Is it factory ammo?

Sweet! Will post after jb'ing it

Did you resolve the problem?

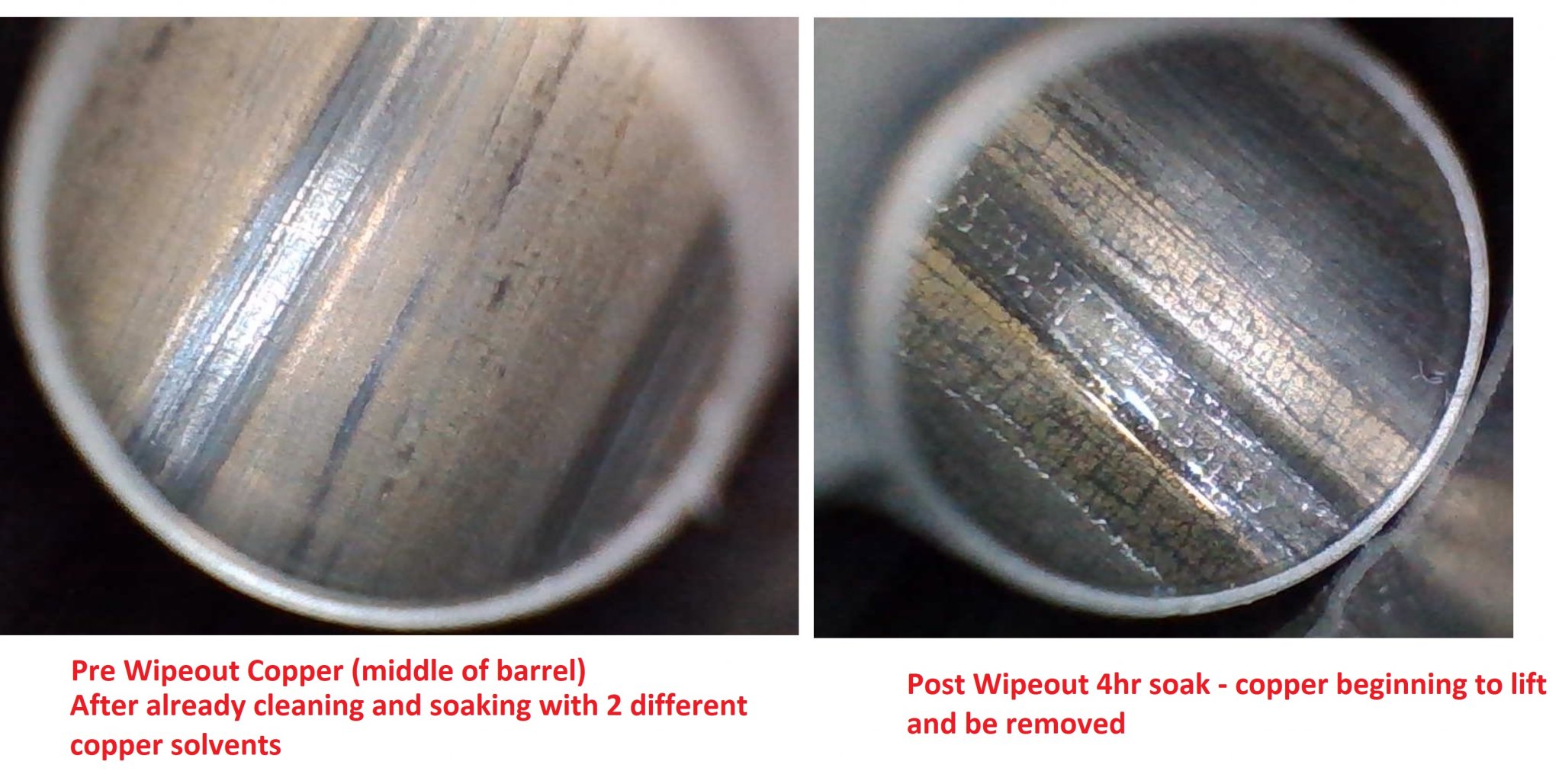

Had an opportunity to take before and after pictures using Wipe-Out for a 4 hour soak. Focus was on the "cracking/scaling" in the throat and stubborn copper in the lands. I tried 2 common copper and carbon solvents previously as described in the previous threads. In my opinion, wipeout definitely got things moving in the right direction. I will do a longer soak for the copper during the holidays and a kroil soak in the throat. It's looking a lot better than previously.

Similar threads

- Replies

- 5

- Views

- 410

- Replies

- 27

- Views

- 857

- Replies

- 2

- Views

- 973

- Replies

- 115

- Views

- 5K