I am starting this topic in response to some discussion that took place in another topic:

http://www.snipershide.com/shooting...-300-norma-magnum.6869034/page-2#post-7288108

The question came up about the "proper" twist rate in a .300 NM, followed by discussion about why one twist rate was or was not working?

My response to that line of questioning is below:

I am going to go out on a limb here, as I am by no means an expert on this subject, but hopefully it will get the conversation started, and maybe some more qualified experts will jump in.

There is talk here about barrel twist rates, and its impact on various parameters. Running through those:

Physical Impact on Bullet = Decreased BC - I have been arguing for years that the physical damage done to bullets could be a factor for consideration. If you look at how "hypothetical" BC numbers don't always work in External Ballistic Calcs, the bullet being damaged as it travels down the barrel could result in an altered/decreased BC.

Physical Impact on Bullet = Decreased Stability - Like the decreased BC, I have also been arguing that the physical damage done to a bullet can impact its physical makeup which can impact stability. If there is enough force/torque to distort/move the jacket in relation to the core, it would obviously impact stability.

I believe the 2 reasons above are why some shooters may be seeing less than optimal performance when they go to a faster twist rate. Basically the increased "twisting forces" does more damage to the bullet which has a negative impact.

Talking to Bryan Litz, he stated this should NOT be an issue with a "properly designed bullet" in a "reasonable twist rate" fired at an "appropriate speed". The key then becomes defining:

"Properly Designed Bullet" - this comes down to the jacket being strong enough, and the jacket and core maintaining their stability. It is a well known fact that a thin jacket bullet can be "blown up" by firing them out of a fast twist rate barrel at very high velocities.

"Reasonable Twist Rate" - I have no idea on this one? I am not sure if going from something like a 10 twist to an 8 twist in some situations could be enough of a change to produce negative consequences? The impact of this variable would obviously be heavily tied into the influence of the other 2 variables.

"Appropriate Speed" - I would normally say this could come into play if it is above 3,000 fps, but I am once again not really sure of the answer?

Increased Twist Rate = Increased Pressure - this is actually one that I DO NOT believe is an issue. If you look at Quickload there is no parameter entry for barrel twist rate. From my understanding that is because barrel twist rate has no impact on Internal Ballistics. Barrel Twist Rate also has almost NO impact on Muzzle Velocity, which would also support the argument that increasing the twist rate does not impact the Internal Ballistics.

IMHO, if people are seeing negative results by going with a faster twist rate in a .300 NM, it is because they are firing a bullet that is being damaged by the faster twist rate to the point that it is impacting performance. Obviously a thin jacket bullet, or a bullet with a poor jacket to core bond, could be susceptible to this.

I wish someone could fire some bullets with varying twist rates and speeds in a water tank so the physical damage to them could be analyzed and compared. I suspect if they did, there would be something there?

*EDIT - besides bullet construction, I also suspect that the Bullet Bearing Surface also comes into play here. The greater the Bearing Surface, the more interaction with the rifling, and the greater the potential for the issues listed above to come into play. In the pursuit of building better Long Range Bullets, the Bearing Surface sizes have gone up significantly.

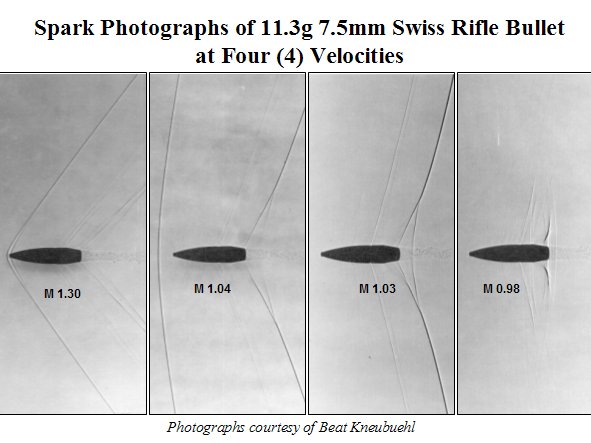

The pictures below, show the bullet damage that I am referring to.

So, the Million Dollar Questions:

- Could a change in twist rate, change the amount of damage occurring to a bullet?

- Is the damage occurring to the bullet having a significant impact on its performance?

- Does that potential negative impact only occur at certain flight speeds, or at all flight speeds?

- And any other questions that someone else wants to throw into the mix?

Please let the discussion begin. Thanks!

http://www.snipershide.com/shooting...-300-norma-magnum.6869034/page-2#post-7288108

The question came up about the "proper" twist rate in a .300 NM, followed by discussion about why one twist rate was or was not working?

My response to that line of questioning is below:

I am going to go out on a limb here, as I am by no means an expert on this subject, but hopefully it will get the conversation started, and maybe some more qualified experts will jump in.

There is talk here about barrel twist rates, and its impact on various parameters. Running through those:

Physical Impact on Bullet = Decreased BC - I have been arguing for years that the physical damage done to bullets could be a factor for consideration. If you look at how "hypothetical" BC numbers don't always work in External Ballistic Calcs, the bullet being damaged as it travels down the barrel could result in an altered/decreased BC.

Physical Impact on Bullet = Decreased Stability - Like the decreased BC, I have also been arguing that the physical damage done to a bullet can impact its physical makeup which can impact stability. If there is enough force/torque to distort/move the jacket in relation to the core, it would obviously impact stability.

I believe the 2 reasons above are why some shooters may be seeing less than optimal performance when they go to a faster twist rate. Basically the increased "twisting forces" does more damage to the bullet which has a negative impact.

Talking to Bryan Litz, he stated this should NOT be an issue with a "properly designed bullet" in a "reasonable twist rate" fired at an "appropriate speed". The key then becomes defining:

"Properly Designed Bullet" - this comes down to the jacket being strong enough, and the jacket and core maintaining their stability. It is a well known fact that a thin jacket bullet can be "blown up" by firing them out of a fast twist rate barrel at very high velocities.

"Reasonable Twist Rate" - I have no idea on this one? I am not sure if going from something like a 10 twist to an 8 twist in some situations could be enough of a change to produce negative consequences? The impact of this variable would obviously be heavily tied into the influence of the other 2 variables.

"Appropriate Speed" - I would normally say this could come into play if it is above 3,000 fps, but I am once again not really sure of the answer?

Increased Twist Rate = Increased Pressure - this is actually one that I DO NOT believe is an issue. If you look at Quickload there is no parameter entry for barrel twist rate. From my understanding that is because barrel twist rate has no impact on Internal Ballistics. Barrel Twist Rate also has almost NO impact on Muzzle Velocity, which would also support the argument that increasing the twist rate does not impact the Internal Ballistics.

IMHO, if people are seeing negative results by going with a faster twist rate in a .300 NM, it is because they are firing a bullet that is being damaged by the faster twist rate to the point that it is impacting performance. Obviously a thin jacket bullet, or a bullet with a poor jacket to core bond, could be susceptible to this.

I wish someone could fire some bullets with varying twist rates and speeds in a water tank so the physical damage to them could be analyzed and compared. I suspect if they did, there would be something there?

*EDIT - besides bullet construction, I also suspect that the Bullet Bearing Surface also comes into play here. The greater the Bearing Surface, the more interaction with the rifling, and the greater the potential for the issues listed above to come into play. In the pursuit of building better Long Range Bullets, the Bearing Surface sizes have gone up significantly.

The pictures below, show the bullet damage that I am referring to.

So, the Million Dollar Questions:

- Could a change in twist rate, change the amount of damage occurring to a bullet?

- Is the damage occurring to the bullet having a significant impact on its performance?

- Does that potential negative impact only occur at certain flight speeds, or at all flight speeds?

- And any other questions that someone else wants to throw into the mix?

Please let the discussion begin. Thanks!

Last edited: