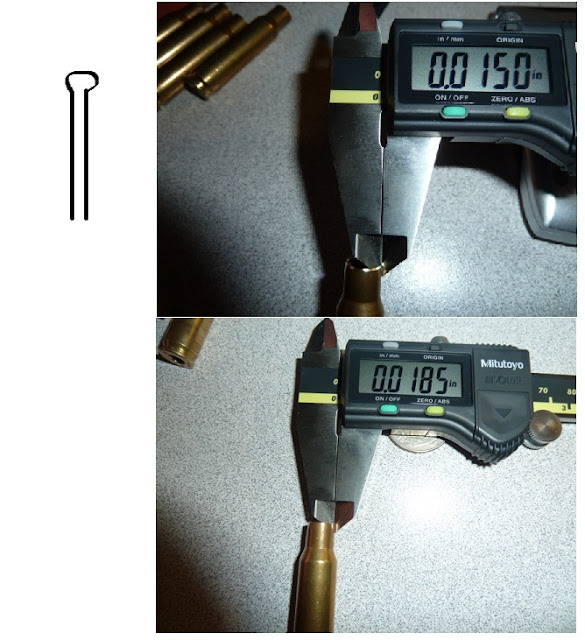

The dents are something like these:

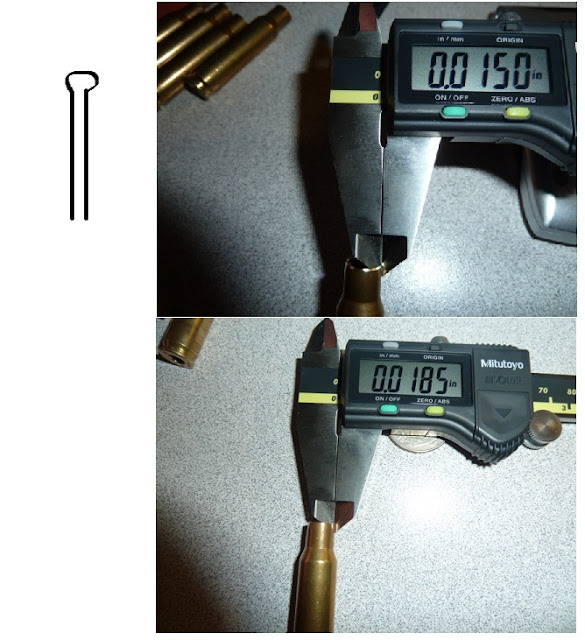

The rim of the neck is "bumped" and it's 0.003" thicker than the actual neck.

I was using the .335 bushing, because .308 + 0.015*2 - 0.003 = 0.335. It's my first time to resize a brass so I don't know what kind of force I should apply. With around 25 lbs of force applied on the handle, It's really hard to get the final 1/2 inch in. I'm not sure I should really brutal-forcing the press but I did. The first one was ok with doubling the force. but the second brass was stuck in the brass with 1/2 inch still out. It took me literally 10 minutes to get it out. It's a bad experience I don't really want to repeat.

What's the best way to resize such brass?

1. thin the rim of the neck? How to thin it when it's not round?

2. make it a bit rounder using plier? then thin the rim?

3. get a 337 brushing? 339/341 bushing? and let the press do the work?

Thanks a lot.

The rim of the neck is "bumped" and it's 0.003" thicker than the actual neck.

I was using the .335 bushing, because .308 + 0.015*2 - 0.003 = 0.335. It's my first time to resize a brass so I don't know what kind of force I should apply. With around 25 lbs of force applied on the handle, It's really hard to get the final 1/2 inch in. I'm not sure I should really brutal-forcing the press but I did. The first one was ok with doubling the force. but the second brass was stuck in the brass with 1/2 inch still out. It took me literally 10 minutes to get it out. It's a bad experience I don't really want to repeat.

What's the best way to resize such brass?

1. thin the rim of the neck? How to thin it when it's not round?

2. make it a bit rounder using plier? then thin the rim?

3. get a 337 brushing? 339/341 bushing? and let the press do the work?

Thanks a lot.