I’ve gone down the case prep center route in the past and I always return to doing things with separate tools. That doesn’t mean you can’t make good ammo or even enjoy the process - it’s really just a personal preference thing in the long run.

Case trimming is a big one as it can be one of the most annoying and tedious processes. Hand cranked trimmers are fine but they get old when you start doing more than 40 cases at a time. There are some great powered trimmers out there, but the one thing that always bothered me is setup and adjusting when swapping cartridges. Obviously not a problem when you’re doing just one, but I do a lot of short action and magnum cartridges and would often have to swap the tool components out regularly and with some that can be time consuming.

For example, I loved the Giraud trimmer, but every time I swapped cartridges I had to replace the insert and adjust it to be just right, and then do the same with the cutting head, which resulted in about 10 minutes of trial and error and some over trimmed cases. Some others are similar in that there’s this arbitrary adjustment you have to do like turn a bolt until it’s trimming the correct amount.

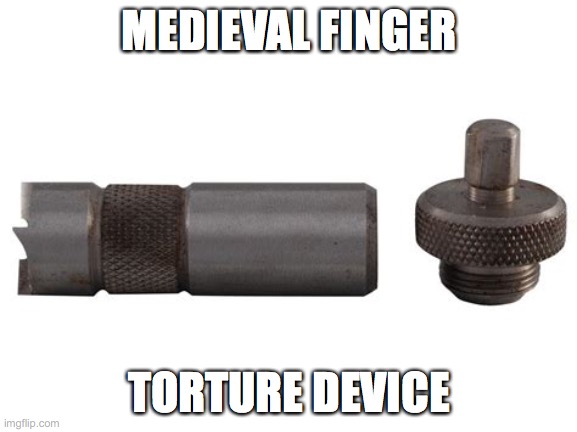

Over the years I settled on a simple system: Little Crow Gunworks WFT. Not the modular WFT2, but the one cartridge WFT. I set it to trim one cartridge, then leave it. I have a rack of 8 different WFTs and when I need one I just throw it in the hand drill and start trimming. Super fast to trim a whole bunch of brass for different cartridges.

There are others out there that do a step better and chamfer/debur while trimming.

Just my trimming evolution - YMMV