Valuable load development approaches such as the Audette ladder test and Dan's OCW are based on finding the powder charge range which yields a minimal effect on the vertical point of impact (POI) as the charge is varied; these are the so called "nodes". While the merit of these methods is clear, a major question is why does this work? How can you add more powder, which results in higher pressure and velocity, yet the POI will actually fall? Everyone appreciates the fact that barrels vibrate at various frequencies but Chris Long developed a bit of a different view in theorizing the propagation of a shock (pressure) wave back and forth from receiver to muzzle. Probably the most useful aspect of his work are several simple equations which enable one to calculate the nodes directly based only on the barrel length, as opposed to needing the sophisticated software required to determine the complex vibration patterns. The nodes are expressed as optimum barrel time (OBT), which is the time the bullet spends in the barrel before exiting the muzzle, in order to avoid the shock (pressure) wave disturbance. So how can this be applied and used? The good news is barrel time is one of the parameters calculated by Quick Load (QL).

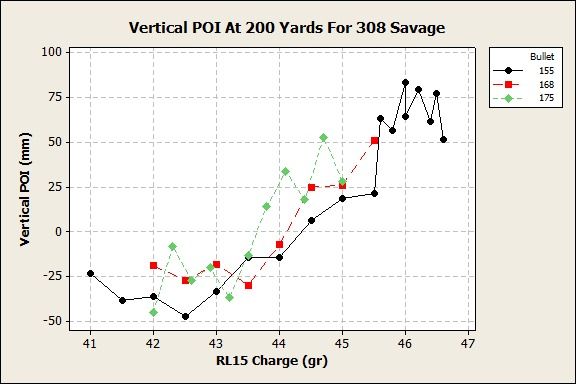

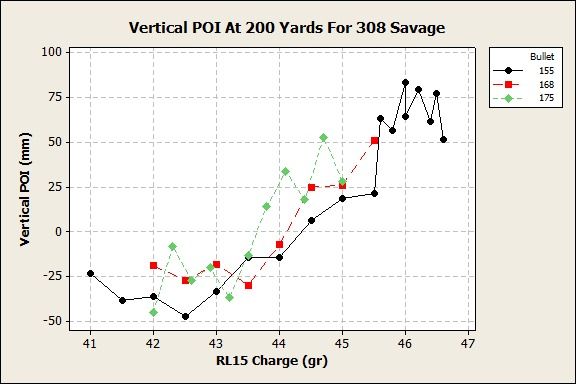

To test this theory I carried out ladder tests for a Savage 308 with a 26" barrel 1:10 twist. Brass included WC and LC which have different capacities, which is an input field in QL. Sierra Match King 168 and 175, plus the 155 Palma bullets were evaluated; the differences in seating depth are also incorporated in QL as these change case capacity. For simplicity only the results for RL 15 powder will be shown here. The vertical POI was measured at 200 yards and the reported results were centered for each bullet type.

First it is interesting to note that the POI node at the low charge of 42.5gr RL15 is similar for the wide range of bullet weights, although the associated pressures and velocities are very different according to QL. Due to the lighter bullet weight, it was possible to extend the charges to find a node for the 155 Palma around 46.5gr.

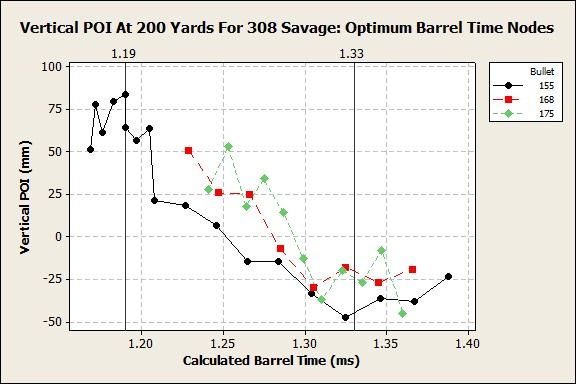

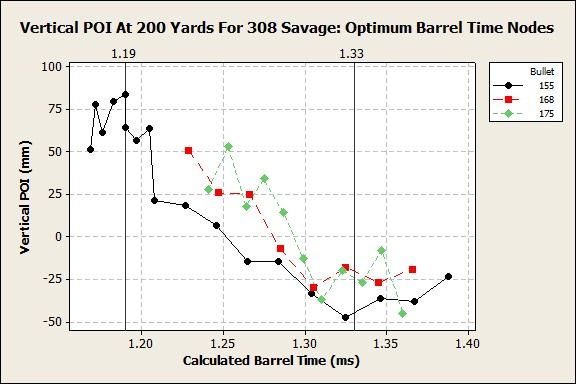

The barrel times for all these cases were determined using Quick Load to see how the results compared to the calculated OBT nodes, which are at 1.19 and 1.33 milli-seconds (ms) for the 26" barrel.

It is evident that the POI nodes match very well at the OBT nodes! I have found similar results for other calibers, bullets, powders as well. So I am convinced the OBT theory is quite valid, and beyond providing a short-cut to minimize time and cost it is also useful to help diagnose other issues. For example, while the seating depth is accounted for in terms of the effect on pressure/velocity/barrel time all of the other complex mechanical aspects of seating into or jumping to the lands is not. So if your are way off on the jump, the OBT calculation should have you in the ballpark when it comes to powder charge so you are not chasing that as well.

Since this was very conclusive evaluation it was time to change something so I cut the barrel back to 20" and found a case of IMR4064. Using Quick Load and the new OBT nodes it was quick and easy to home in on a good POI node with minimal time and effort.

To test this theory I carried out ladder tests for a Savage 308 with a 26" barrel 1:10 twist. Brass included WC and LC which have different capacities, which is an input field in QL. Sierra Match King 168 and 175, plus the 155 Palma bullets were evaluated; the differences in seating depth are also incorporated in QL as these change case capacity. For simplicity only the results for RL 15 powder will be shown here. The vertical POI was measured at 200 yards and the reported results were centered for each bullet type.

First it is interesting to note that the POI node at the low charge of 42.5gr RL15 is similar for the wide range of bullet weights, although the associated pressures and velocities are very different according to QL. Due to the lighter bullet weight, it was possible to extend the charges to find a node for the 155 Palma around 46.5gr.

The barrel times for all these cases were determined using Quick Load to see how the results compared to the calculated OBT nodes, which are at 1.19 and 1.33 milli-seconds (ms) for the 26" barrel.

It is evident that the POI nodes match very well at the OBT nodes! I have found similar results for other calibers, bullets, powders as well. So I am convinced the OBT theory is quite valid, and beyond providing a short-cut to minimize time and cost it is also useful to help diagnose other issues. For example, while the seating depth is accounted for in terms of the effect on pressure/velocity/barrel time all of the other complex mechanical aspects of seating into or jumping to the lands is not. So if your are way off on the jump, the OBT calculation should have you in the ballpark when it comes to powder charge so you are not chasing that as well.

Since this was very conclusive evaluation it was time to change something so I cut the barrel back to 20" and found a case of IMR4064. Using Quick Load and the new OBT nodes it was quick and easy to home in on a good POI node with minimal time and effort.