Hi there,

In need of some help.

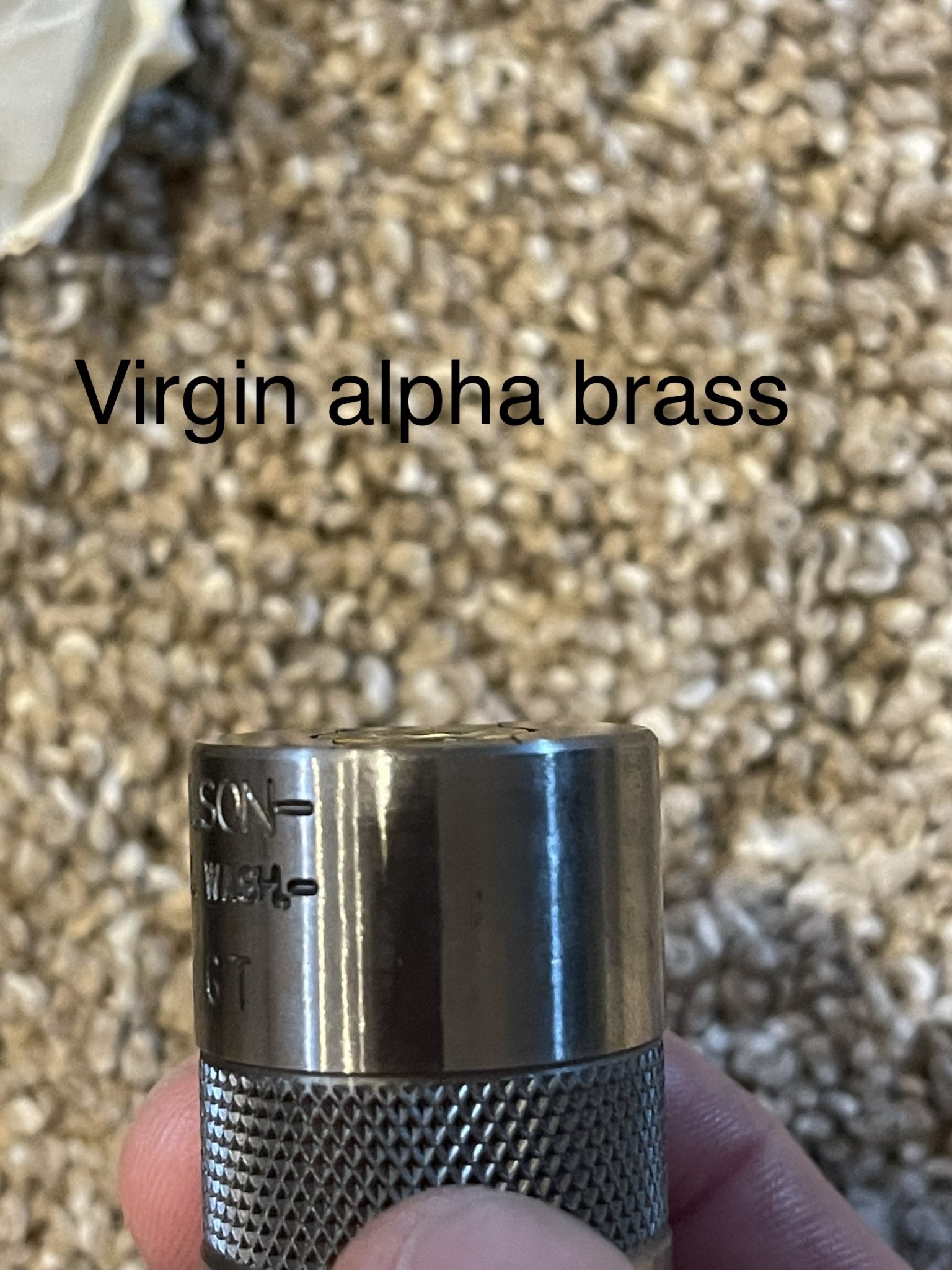

Put on a new proof prefit. Was hard, if not impossible to close bolt on my full length sized ammo. The prefit chamber would accept virgin brass (without bullet).

Also, cannot chamber once fired brass from the same chamber. Pics from case gage:

Notice the protrusion of head and retracted neck.

What’s going on here? What dimension is off?

Thanks

In need of some help.

Put on a new proof prefit. Was hard, if not impossible to close bolt on my full length sized ammo. The prefit chamber would accept virgin brass (without bullet).

Also, cannot chamber once fired brass from the same chamber. Pics from case gage:

Notice the protrusion of head and retracted neck.

What’s going on here? What dimension is off?

Thanks