I was wondering if anyone has any insite about chucking up a factory Remington barrel. My barrel measures .820 at the muzzle and basically has a 2 degree angle from the breech. I am planning on using a blank collet and contouring it to fit the barrel. Anyone have a better way of indicating it in better centers without sacrificing concentricy?

Gunsmithing Chucking up factory Remmy barrel in lathe

- Thread starter ClayDirt

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Re: Chucking up factory Remmy barrel in lathe

what are you trying to accomplish, are you threading the muzzle for a brake if you are there are easer ways to do it. even though you don't get much more accurate than a collet for production work the majority of the barrels arn't truly round of you center the bore of the rifle and take a pass with the cutter just a few thousandths the cut won't be all the way around. but if you are using a collet with the barrel still attached to the receiver you are going to want to support the receiver out the end of the headstock. the other thing to think about is that if the taper isn't constant or cut just a little off the barrel will sit in a different spot in the collet. just my 2 cents.

Justin Bowerman

JB Enterprise

07 ffl in Central CA.

what are you trying to accomplish, are you threading the muzzle for a brake if you are there are easer ways to do it. even though you don't get much more accurate than a collet for production work the majority of the barrels arn't truly round of you center the bore of the rifle and take a pass with the cutter just a few thousandths the cut won't be all the way around. but if you are using a collet with the barrel still attached to the receiver you are going to want to support the receiver out the end of the headstock. the other thing to think about is that if the taper isn't constant or cut just a little off the barrel will sit in a different spot in the collet. just my 2 cents.

Justin Bowerman

JB Enterprise

07 ffl in Central CA.

Re: Chucking up factory Remmy barrel in lathe

What do you plan to do to the barrel??? That will make a huge difference in how you hold it on the lathe.

If you want to contour than make a threaded adapter that will screw on to the breech threads and allow you to hold the barrel in the chuck. Put it in a 4 jaw and center with your normal method. The muzzle can be held in the live center.

If you are trying to work the chamber then chuck the muzzle end up in the 4 jaw and hold the threaded breech end in your steady rest.

Hope that helps some....more info will help us help you more.

Frank

What do you plan to do to the barrel??? That will make a huge difference in how you hold it on the lathe.

If you want to contour than make a threaded adapter that will screw on to the breech threads and allow you to hold the barrel in the chuck. Put it in a 4 jaw and center with your normal method. The muzzle can be held in the live center.

If you are trying to work the chamber then chuck the muzzle end up in the 4 jaw and hold the threaded breech end in your steady rest.

Hope that helps some....more info will help us help you more.

Frank

Re: Chucking up factory Remmy barrel in lathe

Whoops...I guess I should have reloaded the page before posting...

If you're crowning the muzzle than the threaded bushing for the breech will work well and holding the muzzle end with the steady rest will allow you to work on the crown. You can also buy piloted tools from reamer manufacturers like Dave Manson Reamers which allow you to recut the crown without removing the barrel from the receiver.

Hope that helps

Frank

Whoops...I guess I should have reloaded the page before posting...

If you're crowning the muzzle than the threaded bushing for the breech will work well and holding the muzzle end with the steady rest will allow you to work on the crown. You can also buy piloted tools from reamer manufacturers like Dave Manson Reamers which allow you to recut the crown without removing the barrel from the receiver.

Hope that helps

Frank

Re: Chucking up factory Remmy barrel in lathe

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: biffj</div><div class="ubbcode-body">Whoops...I guess I should have reloaded the page before posting...

If you're crowning the muzzle than the threaded bushing for the breech will work well and holding the muzzle end with the steady rest will allow you to work on the crown. You can also buy piloted tools from reamer manufacturers like Dave Manson Reamers which allow you to recut the crown without removing the barrel from the receiver.

Hope that helps

Frank </div></div> If you hold the muzzle end in a steady rest how do you dial in the bore? the muzzle needs to be in a four jaw chuck.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: biffj</div><div class="ubbcode-body">Whoops...I guess I should have reloaded the page before posting...

If you're crowning the muzzle than the threaded bushing for the breech will work well and holding the muzzle end with the steady rest will allow you to work on the crown. You can also buy piloted tools from reamer manufacturers like Dave Manson Reamers which allow you to recut the crown without removing the barrel from the receiver.

Hope that helps

Frank </div></div> If you hold the muzzle end in a steady rest how do you dial in the bore? the muzzle needs to be in a four jaw chuck.

Re: Chucking up factory Remmy barrel in lathe

Will the barrel fit thru the headstock, If so spider on the chamber side, spider or 4 jaw chuck on the muzzle end. Indicate both ends to run tru and go ahead and cut the crown. If it wont go thru the headstock you may have to use a steady rest.

Will the barrel fit thru the headstock, If so spider on the chamber side, spider or 4 jaw chuck on the muzzle end. Indicate both ends to run tru and go ahead and cut the crown. If it wont go thru the headstock you may have to use a steady rest.

Re: Chucking up factory Remmy barrel in lathe

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: ClayDirt</div><div class="ubbcode-body">I was wondering if anyone has any insite about chucking up a factory Remington barrel. My barrel measures .820 at the muzzle and basically has a 2 degree angle from the breech. I am planning on using a blank collet and contouring it to fit the barrel. Anyone have a better way of indicating it in better centers without sacrificing concentricy? </div></div>

since the bore is very rarely going to be concentric to the od of the barrel, i wouldn't do any precision barrel work with a collet and no way to dial in the bore.

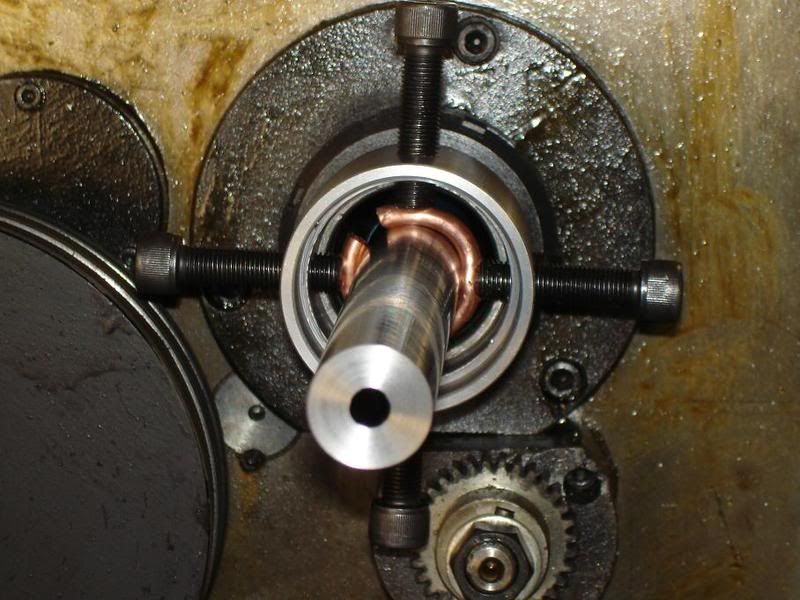

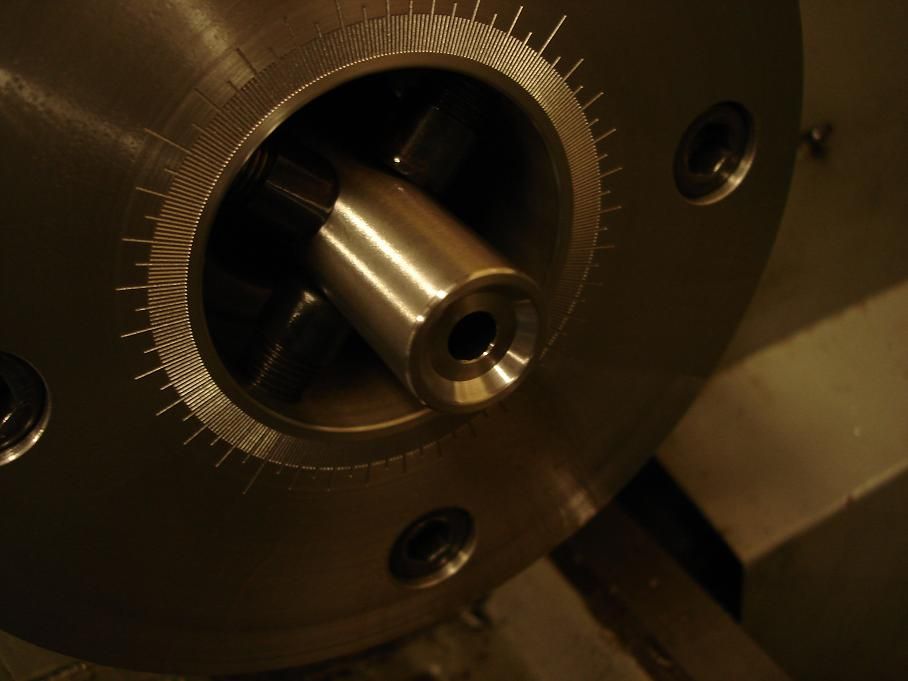

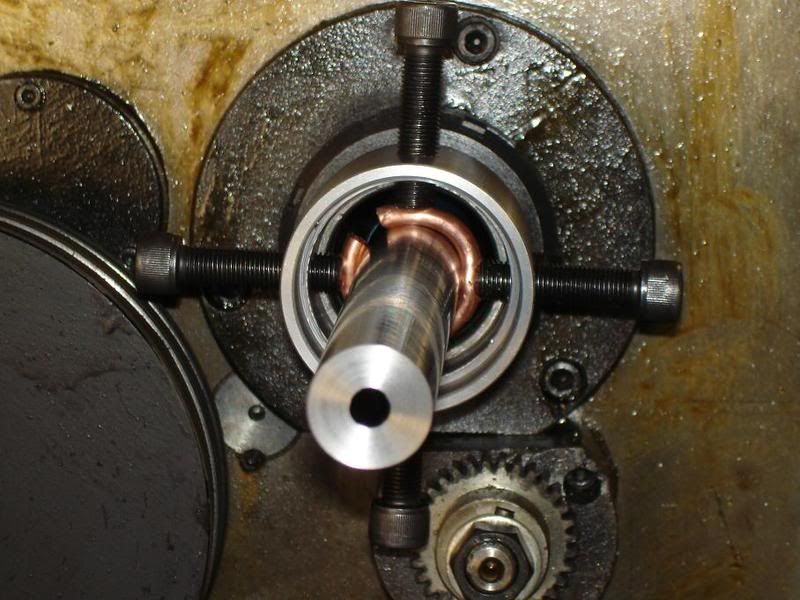

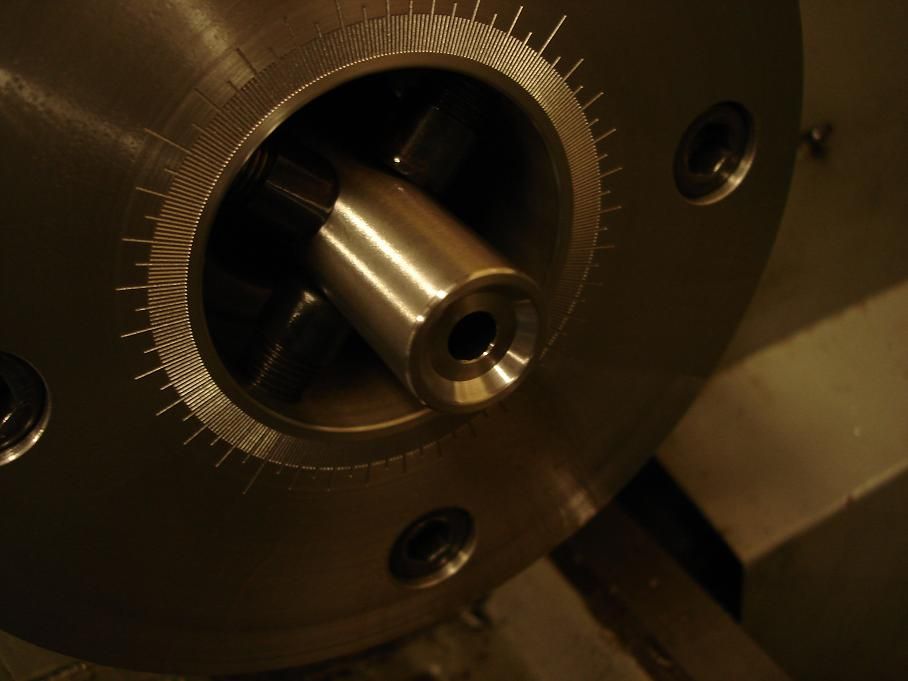

factory barrel or a barrel from one of the quality barrel manufactures, i chuck them all up the same way. i use a home shop made 4 jaw spider chuck and rear spider chuck and hold the barrel through the spindle bore. i then gimble the barrel between the spiders until an indicator reads less than 2 tenths of runout in two places off of a tapered ptg range rod and fitted bushing in the bore.

http://www.youtube.com/watch?v=FcTvr7LeMEk

don't get me wrong, a collet would be a great way to hold the barrel if you had a way to gimble it to ensure the bore is parralel and concentric to the spindle at the end you are working on.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: ClayDirt</div><div class="ubbcode-body">I was wondering if anyone has any insite about chucking up a factory Remington barrel. My barrel measures .820 at the muzzle and basically has a 2 degree angle from the breech. I am planning on using a blank collet and contouring it to fit the barrel. Anyone have a better way of indicating it in better centers without sacrificing concentricy? </div></div>

since the bore is very rarely going to be concentric to the od of the barrel, i wouldn't do any precision barrel work with a collet and no way to dial in the bore.

factory barrel or a barrel from one of the quality barrel manufactures, i chuck them all up the same way. i use a home shop made 4 jaw spider chuck and rear spider chuck and hold the barrel through the spindle bore. i then gimble the barrel between the spiders until an indicator reads less than 2 tenths of runout in two places off of a tapered ptg range rod and fitted bushing in the bore.

http://www.youtube.com/watch?v=FcTvr7LeMEk

don't get me wrong, a collet would be a great way to hold the barrel if you had a way to gimble it to ensure the bore is parralel and concentric to the spindle at the end you are working on.

Re: Chucking up factory Remmy barrel in lathe

what kind of barrel is that?

what kind of barrel is that?

Re: Chucking up factory Remmy barrel in lathe

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: NoLimitz</div><div class="ubbcode-body">what kind of barrel is that? </div></div>

i couldn't tell you from the pictures.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: NoLimitz</div><div class="ubbcode-body">what kind of barrel is that? </div></div>

i couldn't tell you from the pictures.

Re: Chucking up factory Remmy barrel in lathe

you know anything about a good 300WM barrel as far as kriger, rock, etc and a QD suppressor surefire/aac

you know anything about a good 300WM barrel as far as kriger, rock, etc and a QD suppressor surefire/aac

Re: Chucking up factory Remmy barrel in lathe

hey i have to fly but i have a stock 700P in 300WM and i want to shoot to 1500yds. a new barrel and a suppressor is planned. any info on this cal would help. email if possible [email protected]

hey i have to fly but i have a stock 700P in 300WM and i want to shoot to 1500yds. a new barrel and a suppressor is planned. any info on this cal would help. email if possible [email protected]

Re: Chucking up factory Remmy barrel in lathe

Remington barrels can be snaky. You want to shoot it to 1500 yds, walk from the gun and place your own target...shoot...that experience alone will convince you need a spotting scope more than a rifle. and probably a bigger target.

Remington barrels can be snaky. You want to shoot it to 1500 yds, walk from the gun and place your own target...shoot...that experience alone will convince you need a spotting scope more than a rifle. and probably a bigger target.

Re: Chucking up factory Remmy barrel in lathe

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: toolmaker64</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: biffj</div><div class="ubbcode-body">Whoops...I guess I should have reloaded the page before posting...

If you're crowning the muzzle than the threaded bushing for the breech will work well and holding the muzzle end with the steady rest will allow you to work on the crown. You can also buy piloted tools from reamer manufacturers like Dave Manson Reamers which allow you to recut the crown without removing the barrel from the receiver.

Hope that helps

Frank </div></div> If you hold the muzzle end in a steady rest how do you dial in the bore? the muzzle needs to be in a four jaw chuck. </div></div>

Holding the muzzle in the steady rest allows you to adjust the position of the muzzle to keep it true. The steady rest has 3 independent adjustments and will allow the muzzle to be crowned true. By dialing in the breech end in the 4 jaw you insure the barrel is centered too. Its pretty simple, requires no oddball tools be made and works as well as any of the other methods.

Hope that answers the question.

Frank

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: toolmaker64</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: biffj</div><div class="ubbcode-body">Whoops...I guess I should have reloaded the page before posting...

If you're crowning the muzzle than the threaded bushing for the breech will work well and holding the muzzle end with the steady rest will allow you to work on the crown. You can also buy piloted tools from reamer manufacturers like Dave Manson Reamers which allow you to recut the crown without removing the barrel from the receiver.

Hope that helps

Frank </div></div> If you hold the muzzle end in a steady rest how do you dial in the bore? the muzzle needs to be in a four jaw chuck. </div></div>

Holding the muzzle in the steady rest allows you to adjust the position of the muzzle to keep it true. The steady rest has 3 independent adjustments and will allow the muzzle to be crowned true. By dialing in the breech end in the 4 jaw you insure the barrel is centered too. Its pretty simple, requires no oddball tools be made and works as well as any of the other methods.

Hope that answers the question.

Frank

Re: Chucking up factory Remmy barrel in lathe

I have to admit i have never had to use a steady rest in my line of work. How does the SR allow the muzzle end of the barrel to ''run out'' if the I.D. and the O.D. are not concentric.? Is'nt the purpose of a SR to keep the work in a fixed posistion like when you are turning a shaft/barrel between centers.

I have to admit i have never had to use a steady rest in my line of work. How does the SR allow the muzzle end of the barrel to ''run out'' if the I.D. and the O.D. are not concentric.? Is'nt the purpose of a SR to keep the work in a fixed posistion like when you are turning a shaft/barrel between centers.

Re: Chucking up factory Remmy barrel in lathe

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: toolmaker64</div><div class="ubbcode-body">I have to admit i have never had to use a steady rest in my line of work. How does the SR allow the muzzle end of the barrel to ''run out'' if the I.D. and the O.D. are not concentric.? Is'nt the purpose of a SR to keep the work in a fixed posistion like when you are turning a shaft/barrel between centers.</div></div>

Well I gotta admit you've got a very good point there. I don't normally work on factory barrels....I normally cut the muzzle threads, profile and then use the steady rest to finish off the crown. I can see where the steady rest won't help if the bore isn't concentric. I'll also have to admit that the few factory barrels I've worked on usually have some runout so never mind on the steady rest.....

Frank

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: toolmaker64</div><div class="ubbcode-body">I have to admit i have never had to use a steady rest in my line of work. How does the SR allow the muzzle end of the barrel to ''run out'' if the I.D. and the O.D. are not concentric.? Is'nt the purpose of a SR to keep the work in a fixed posistion like when you are turning a shaft/barrel between centers.</div></div>

Well I gotta admit you've got a very good point there. I don't normally work on factory barrels....I normally cut the muzzle threads, profile and then use the steady rest to finish off the crown. I can see where the steady rest won't help if the bore isn't concentric. I'll also have to admit that the few factory barrels I've worked on usually have some runout so never mind on the steady rest.....

Frank

Re: Chucking up factory Remmy barrel in lathe

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: biffj</div><div class="ubbcode-body"> <div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: toolmaker64</div><div class="ubbcode-body">I have to admit i have never had to use a steady rest in my line of work. How does the SR allow the muzzle end of the barrel to ''run out'' if the I.D. and the O.D. are not concentric.? Is'nt the purpose of a SR to keep the work in a fixed posistion like when you are turning a shaft/barrel between centers.</div></div>

Well I gotta admit you've got a very good point there. I don't normally work on factory barrels....I normally cut the muzzle threads, profile and then use the steady rest to finish off the crown. I can see where the steady rest won't help if the bore isn't concentric. I'll also have to admit that the few factory barrels I've worked on usually have some runout so never mind on the steady rest.....

Frank </div></div>

There are techniques that will allow the use of a steady rest when the bore and od of a barrel are not concentric.I have used a sacrificial sleeve on the barrel turned between centers to be concentric with the bore and then run the steady fingers on the trued sleeve. Granted it is a longer way to go and sometimes tolerances will stack up but some machines allow for few options and we have to make do with what we have

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: biffj</div><div class="ubbcode-body"> <div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: toolmaker64</div><div class="ubbcode-body">I have to admit i have never had to use a steady rest in my line of work. How does the SR allow the muzzle end of the barrel to ''run out'' if the I.D. and the O.D. are not concentric.? Is'nt the purpose of a SR to keep the work in a fixed posistion like when you are turning a shaft/barrel between centers.</div></div>

Well I gotta admit you've got a very good point there. I don't normally work on factory barrels....I normally cut the muzzle threads, profile and then use the steady rest to finish off the crown. I can see where the steady rest won't help if the bore isn't concentric. I'll also have to admit that the few factory barrels I've worked on usually have some runout so never mind on the steady rest.....

Frank </div></div>

There are techniques that will allow the use of a steady rest when the bore and od of a barrel are not concentric.I have used a sacrificial sleeve on the barrel turned between centers to be concentric with the bore and then run the steady fingers on the trued sleeve. Granted it is a longer way to go and sometimes tolerances will stack up but some machines allow for few options and we have to make do with what we have

Similar threads

- Replies

- 17

- Views

- 1K

- Replies

- 2

- Views

- 427

- Replies

- 10

- Views

- 769