I was under the impression that 135 degree angled split point drill bits were better for metal such as steel, but some people say 118 degree split point drill bits are better for cupped or knurled set screws and some say 135 are better. if anyone can give me some solid information on this it would be greatly appreciated

Correct split point drill bit angle for cupped or knurled set screws that are 10/32 x 3/16? 118 degree angle vs 135 degree angle? Or something else?

- Thread starter URGILOVERR

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Might want to post this in the Armory subforum....prob get a better response. Just a thoughtI was under the impression that 135 degree angled split point drill bits were better for metal such as steel, but some people say 118 degree split point drill bits are better for cupped or knurled set screws and some say 135 are better. if anyone can give me some solid information on this it would be greatly appreciated

Machinist by trade and I never use anything but 135 degree split point bits. They resist walking far better and 95% of the time I do not need to centerdrill first. Stainless steel,copper aluminum 4140 4150 all I deal with if drilling get 135 degree bits.

OK why the reference to set screws?

OK why the reference to set screws?

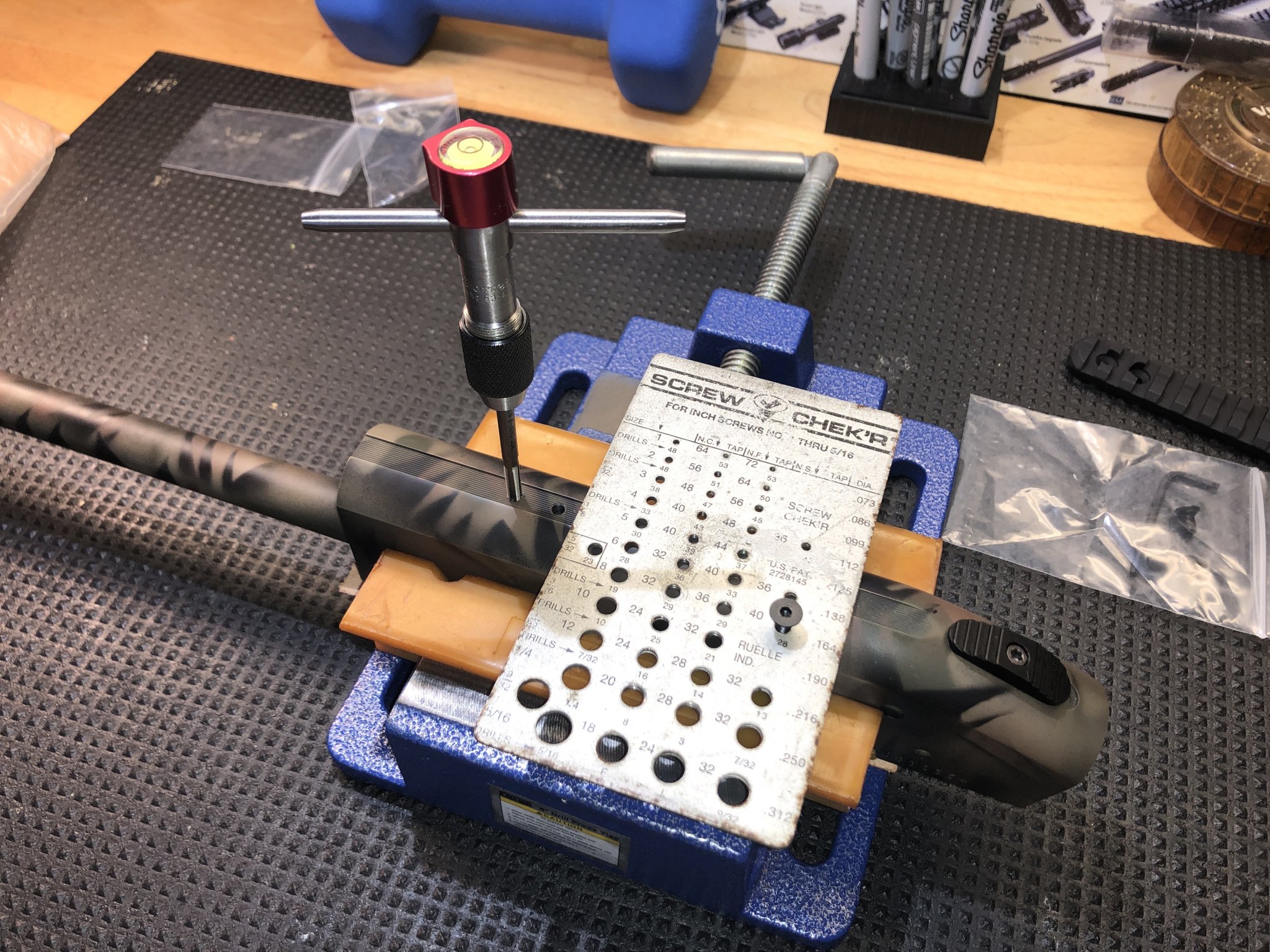

Some general advice.The drill bit tip angle has nothing to do with the fastener that the drill is going to tap the 10-32 hole. Use a #21 drill bit. What matters, is using center point starter drill bit (~5% larger than the #21) so the #21 doesn't walk off the center of the desired drill site. A rigid setup so the part being drilled doesn't move when the drill bit engages the work piece. Use a new drill bit ( a few bucks), lubricant, gentle pressure with pecks until the hole diameter is established. Tapping the hole square is the next task. You can free hand tap it (I like to use the magnetic centering bubble) or if you have a drill press, then use the tap guide immediately after your hole is drilled, so the tap is perfectly centered. IF it is a thru-hole then use a taper or plut style tap, IF it is a blind hole, it needs to be deeper than the fastener and will need to use a bottom tap.

Machinist by trade and I never use anything but 135 degree split point bits. They resist walking far better and 95% of the time I do not need to centerdrill first. Stainless steel,copper aluminum 4140 4150 all I deal with if drilling get 135 degree bits.

OK why the reference to set screws?Thank you man, I just wanted to reference the size of the set screws didn’t know if it was needed I have a 5/32 drill bit that just fits into the hole for the set screws no need to go any bigger correct?

Thank you very much for the info

A

Machinist by trade and I never use anything but 135 degree split point bits. They resist walking far better and 95% of the time I do not need to centerdrill first. Stainless steel,copper aluminum 4140 4150 all I deal with if drilling get 135 degree bits.

OK why the reference to set screws?

Thank you very much for the info, I was just putting in the size of the set screws becuse I didn’t know if it was needed or not, I have a 5/32 drill bit that just fits into the hole for the set screws in the gas block, no need to go bigger correct?

Thank you very much for the info, I was just putting in the size of the set screws becuse I didn’t know if it was needed or not, I have a 5/32 drill bit that just fits into the hole for the set screws in the gas block, no need to go bigger correct?

You are wanting to use the gas block holes as a drill jig to start dimple holes in your barrel? Use a center punch instead so you don't bugger up your threads with a drill bit. Then drill from there with the block removed.

@Stikeeagle1 shows using a nice rigid kneemill for drilling and true to verticle hole alignment tapping. Good setup for this kind of work saves trouble.

You are wanting to use the gas block holes as a drill jig to start dimple holes in your barrel? Use a center punch instead so you don't bugger up your threads with a drill bit. Then drill from there with the block removed.

@Stikeeagle1 shows using a nice rigid kneemill for drilling and true to verticle hole alignment tapping. Good setup for this kind of work saves trouble.

No I’m not, I’m using the SLR jig I just used the 5/32 drill bit to see the fit when inserted into the gas block holes to see if it was the correct size, I did no drilling or twisting just used it like a pin gauge. The drill press is covered as well thank you for the response I appreciate it.Thank you very much for the info, I was just putting in the size of the set screws becuse I didn’t know if it was needed or not, I have a 5/32 drill bit that just fits into the hole for the set screws in the gas block, no need to go bigger correct?

You are wanting to use the gas block holes as a drill jig to start dimple holes in your barrel? Use a center punch instead so you don't bugger up your threads with a drill bit. Then drill from there with the block removed.

@Stikeeagle1 shows using a nice rigid kneemill for drilling and true to verticle hole alignment tapping. Good setup for this kind of work saves trouble.

Similar threads

- Replies

- 3

- Views

- 302

- Replies

- 39

- Views

- 10K

- Replies

- 25

- Views

- 6K