*UPDATE*

F/S Thread:

www.snipershide.com

www.snipershide.com

Hi all,

I am in the process of building a new hunting rifle, and will be using Titanium hardware through out as I am neurotic and rusting hardware drives me insane. I also abuse my stuff quite a bit...great combo.

Anyway, I ordered up a bunch of hardware in Titanium from Ti64 in Texas and RaceTi in England for my rifle, stock, and optic. Wanted to share the optic stuff since I am done with it.

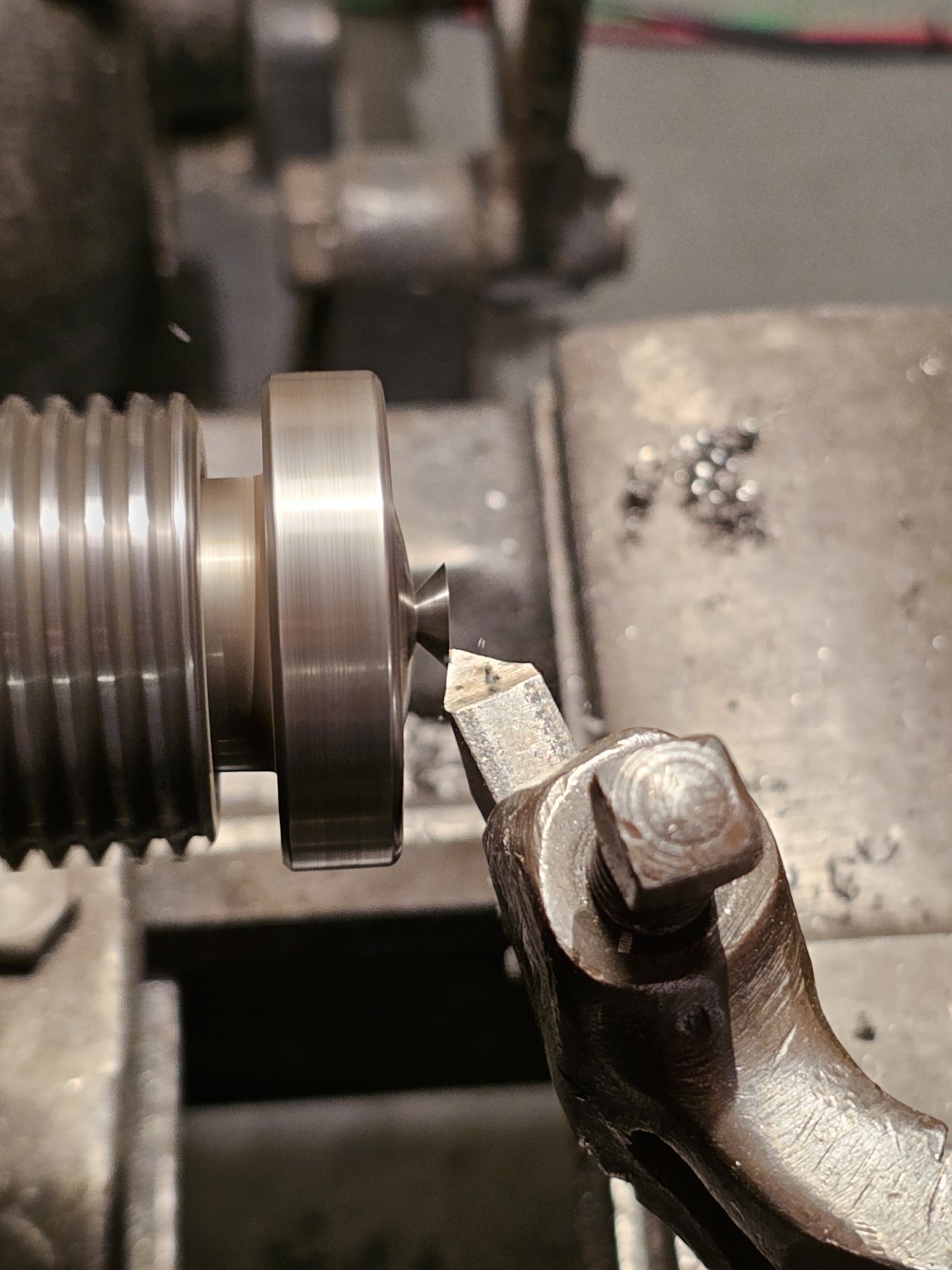

The Spuhr rings use a non standard screw, so I needed to turn all the heads down on a lathe:

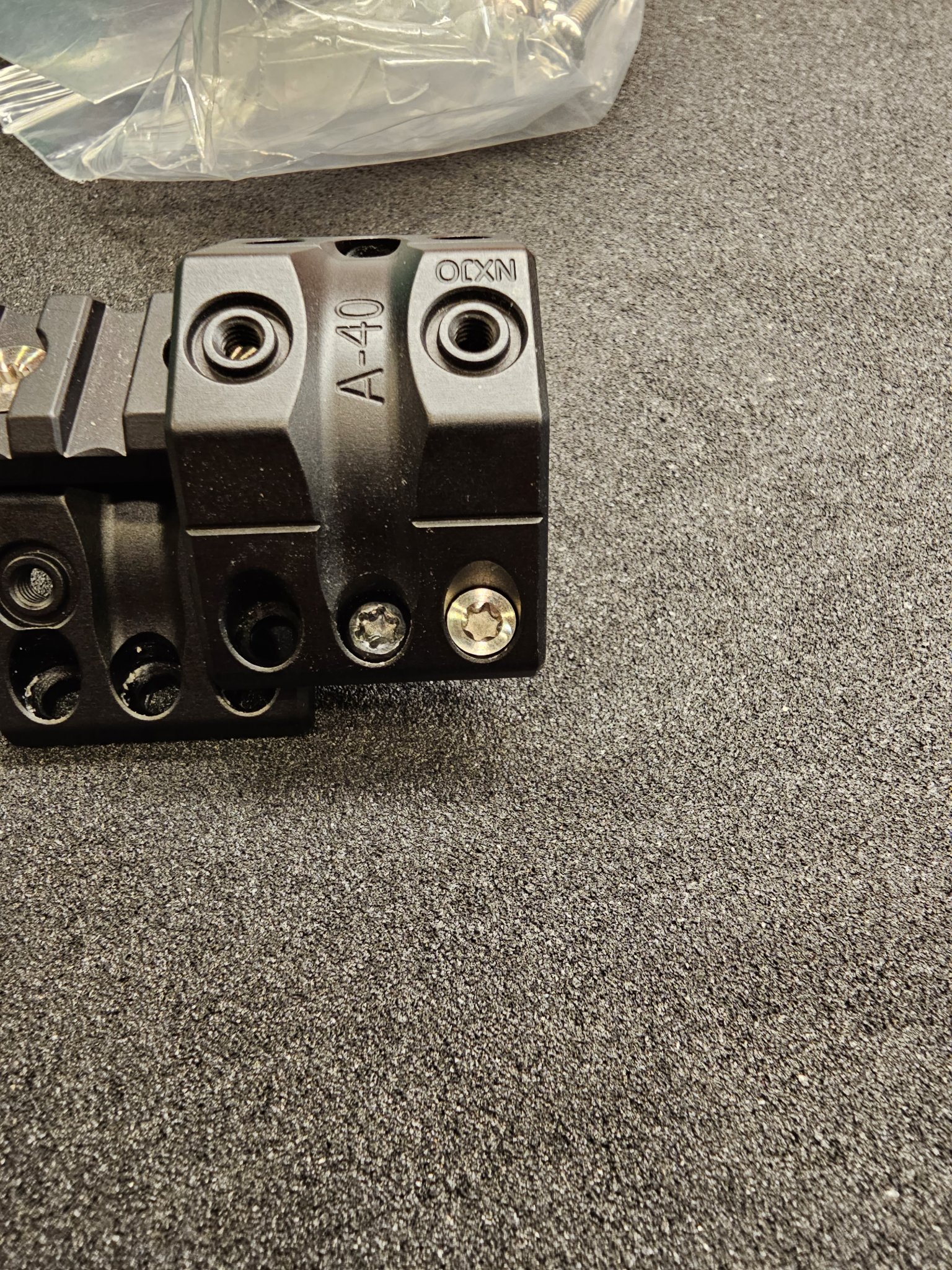

An added benefit of this, which many Spuhr owners will appreciate, is the deeper bit depth in the screw head:

The attachments work with standard M4 x 10 countersunk screws:

The cross bolts I decided to go from a bolt and washer to a flanged bolt from RaceTi:

Here are the final pics:

F/S Thread:

Optics - Custom Titanium Hardware for Spuhr Mounts

I recently put together some custom titanium hardware for my Spuhr mount, and after an overwhelmingly positive response from members of the community in that thread I've decided to offer a few sets for sale. Here is the thread for more information...

Hi all,

I am in the process of building a new hunting rifle, and will be using Titanium hardware through out as I am neurotic and rusting hardware drives me insane. I also abuse my stuff quite a bit...great combo.

Anyway, I ordered up a bunch of hardware in Titanium from Ti64 in Texas and RaceTi in England for my rifle, stock, and optic. Wanted to share the optic stuff since I am done with it.

The Spuhr rings use a non standard screw, so I needed to turn all the heads down on a lathe:

An added benefit of this, which many Spuhr owners will appreciate, is the deeper bit depth in the screw head:

The attachments work with standard M4 x 10 countersunk screws:

The cross bolts I decided to go from a bolt and washer to a flanged bolt from RaceTi:

Here are the final pics:

Last edited: