I appreciate the ongoing interest in this hardware however the batch has been sold out and as of now I do not plan to make more due to the time and labor involved. If this changes for one reason or another in the future I will certainly provide an update to the community. Thank you to those who have participated and I hope you enjoy them!

*UPDATE, 5/24/23*

500 screws in my hand! I'll be firing up the lathe and getting these all done Saturday the 27th; expect invoices Sunday the 28th and I will be shipping these starting Monday the 29th!

*UPDATE, 5/22/23*

Screws have shipped to me! Should be cutting them this weekend.

*UPDATE, 4/17/23*

FYI to all interested; I am being told 4-6 week lead time on the ring screws that I turn down on the lathe. I will keep everyone posted on whether they will be arriving earlier or not.

*UPDATE, 4/13/23*

Hardware has been ordered! I will follow up with each of you when I am ready to ship.

Pricing and names for kits:

SP12R4C - 12x 10mm T20 Ring Screws, 4x 35mm or 20mm T25 Flanged Cross Bolts - $100 to your door

SP12R5C - 12x 10mm T20 Ring Screws, 5x 35mm or 20mm T25 Flanged Cross Bolts - $105 to your door

SP10R4C - 10x 10mm T20 Ring Screws, 4x 35mm or 20mm T25 Flanged Cross Bolts - $90 to your door

SP12R0C - 12x 10mm T20 Ring Screws Only - $85 to your door

SP10R0C - 10x 10mm T20 Ring Screws Only - $75 to your door

Add-ons:

SP1R0C - 1x 10mm T20 Ring / Accessory Screws - $7 to your door

SP0R1C - 1x 35mm or 20mm T25 Flanged Cross Bolt - $5 to your door

*All kits utilize USA Made, Grade 5 Ti-Al6-V4 Ring Screws and UK Made, Grade 5 Ti-Al6-V4 Flanged Cross Bolts each with rolled threads.

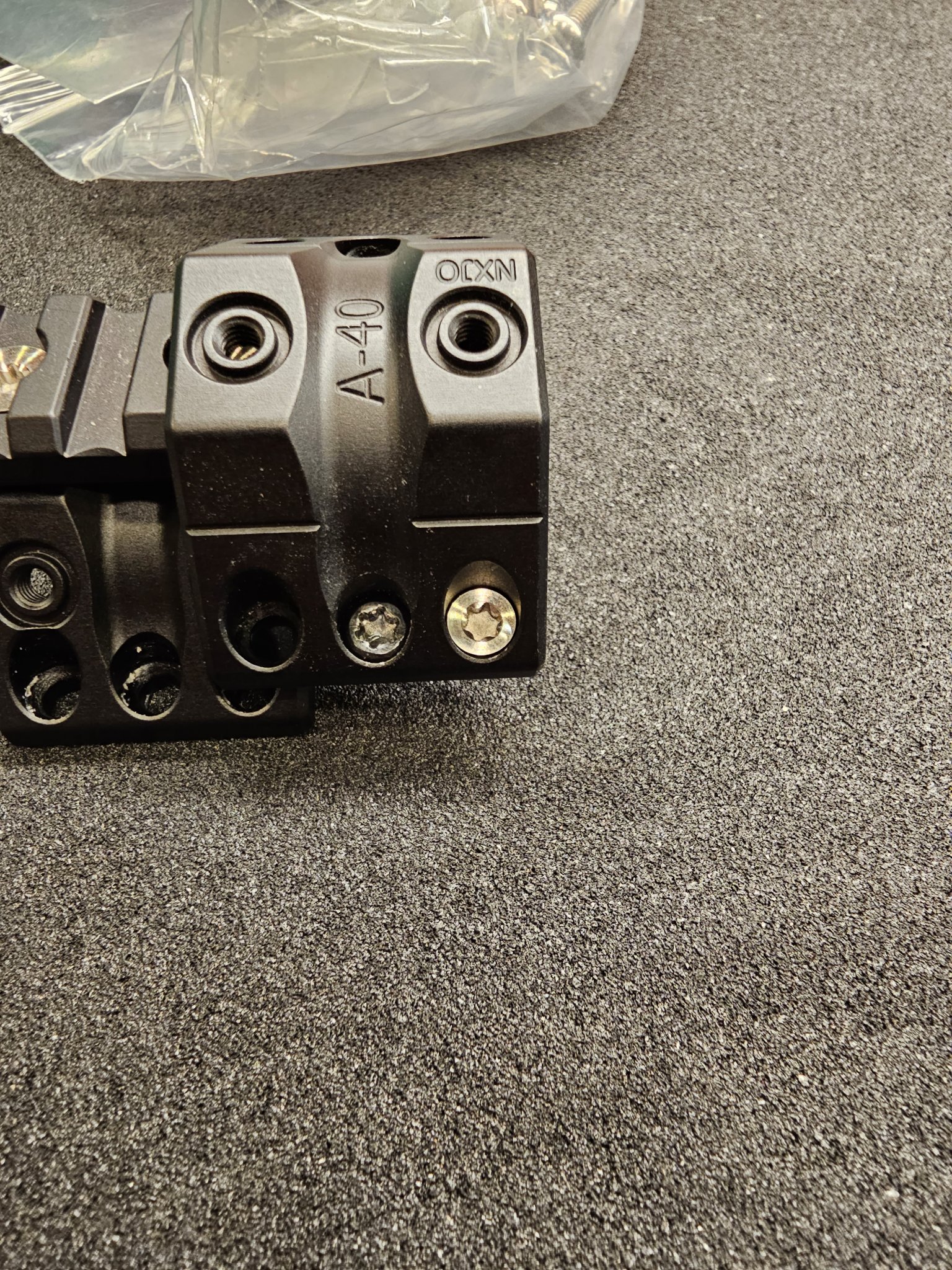

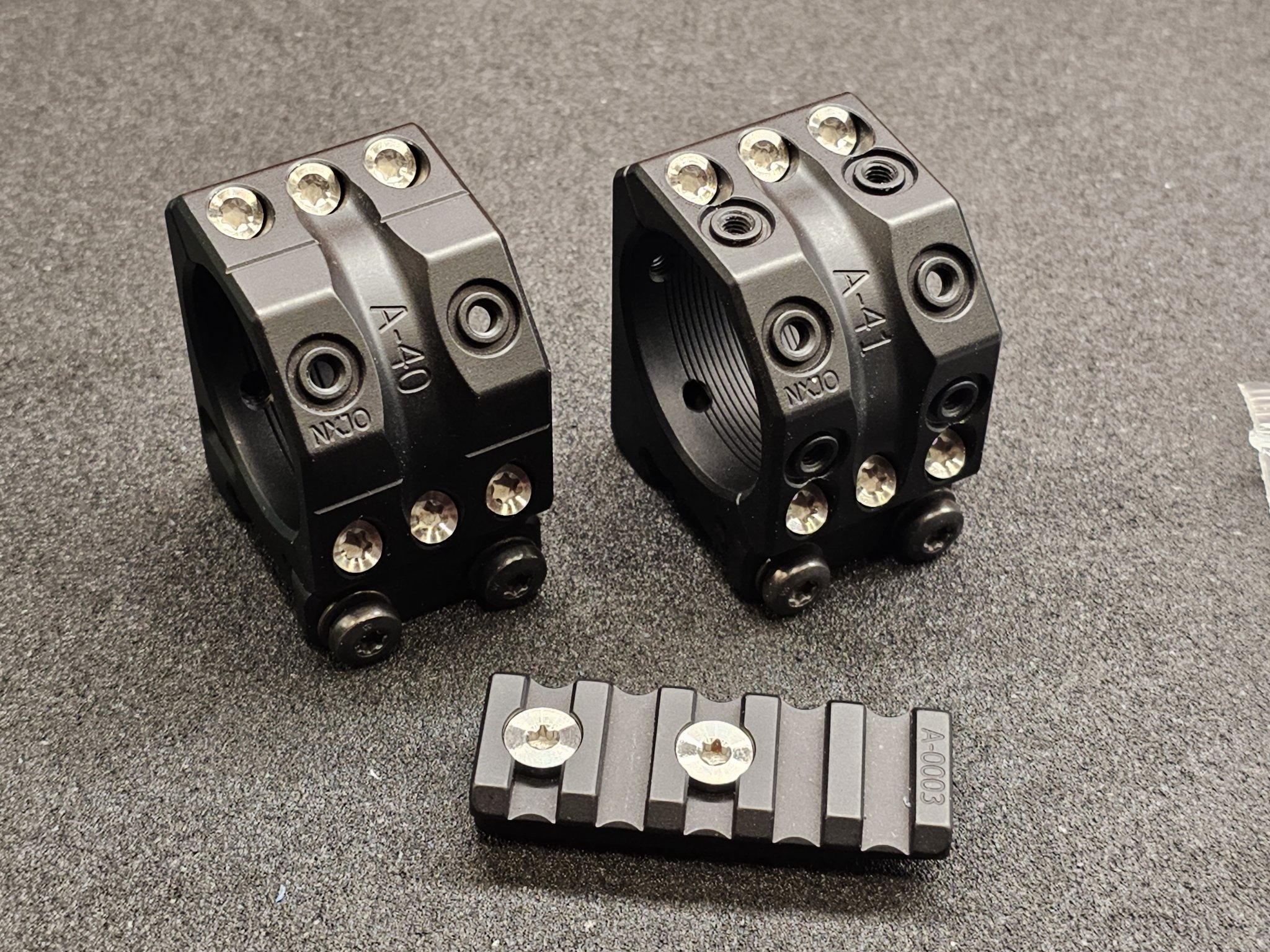

I recently put together some custom titanium hardware for my Spuhr mount, and after an overwhelmingly positive response from members of the community in that thread I've decided to offer a few sets for sale.

Here is the thread for more information:

www.snipershide.com

www.snipershide.com

The screws (US Made) and cross bolts (UK Made) are Grade 5 Ti-Al6-V4 (titanium) with rolled threads. Because the Spuhr mount does not use hardware in sizes for the rings that are readily available in titanium, I turn these down on our lathe. Additionally, I decided to incorporate a flanged bolt for the cross bolts instead of the standard bolt and washer.

Benefits of this hardware are:

- Complete corrosion resistance

- Lighter weight

- Much deeper bit depth in the screw head

- Calculated to use the same lubricated torque specs as your standard hardware. A thread locker, lubricant, or Anti-seize should be used same as your steel hardware which comes from the factory with a dry film lube applied.

- More consistent pre-load. Because titanium is of a higher yield strength and lower Youngs Modulus compared to the steel in question, it will absorb more displacement (can elongate more, think of the screw as a spring) without the pre load changing. Pre load will vary under stress in any fastener, but far less in titanium compared to steel. Here that means less change in preload or opportunity for loosening as a result of recoil or vibration.

I have a number of people interested but would like to do a run of at least 20 sets to start. If you are interested, please post the following:

- Spuhr Mount Model #

- Number of sets

- Required extra hardware for attachments, spares, etc.

Pricing will start at $100 Shipped to your door for a set of 12x ring screws and 4x cross bolts. I will of course modify down for QD sets, sets with less ring screws, etc. and up for spares, accessories, etc. I am also happy to work with someone on developing a hunting mount set, your hardware will be free.

Please reach out with any questions. Thank you for your time and interest.

- Andrew

*UPDATE, 5/24/23*

500 screws in my hand! I'll be firing up the lathe and getting these all done Saturday the 27th; expect invoices Sunday the 28th and I will be shipping these starting Monday the 29th!

*UPDATE, 5/22/23*

Screws have shipped to me! Should be cutting them this weekend.

*UPDATE, 4/17/23*

FYI to all interested; I am being told 4-6 week lead time on the ring screws that I turn down on the lathe. I will keep everyone posted on whether they will be arriving earlier or not.

*UPDATE, 4/13/23*

Hardware has been ordered! I will follow up with each of you when I am ready to ship.

Pricing and names for kits:

SP12R4C - 12x 10mm T20 Ring Screws, 4x 35mm or 20mm T25 Flanged Cross Bolts - $100 to your door

SP12R5C - 12x 10mm T20 Ring Screws, 5x 35mm or 20mm T25 Flanged Cross Bolts - $105 to your door

SP10R4C - 10x 10mm T20 Ring Screws, 4x 35mm or 20mm T25 Flanged Cross Bolts - $90 to your door

SP12R0C - 12x 10mm T20 Ring Screws Only - $85 to your door

SP10R0C - 10x 10mm T20 Ring Screws Only - $75 to your door

Add-ons:

SP1R0C - 1x 10mm T20 Ring / Accessory Screws - $7 to your door

SP0R1C - 1x 35mm or 20mm T25 Flanged Cross Bolt - $5 to your door

*All kits utilize USA Made, Grade 5 Ti-Al6-V4 Ring Screws and UK Made, Grade 5 Ti-Al6-V4 Flanged Cross Bolts each with rolled threads.

I recently put together some custom titanium hardware for my Spuhr mount, and after an overwhelmingly positive response from members of the community in that thread I've decided to offer a few sets for sale.

Here is the thread for more information:

Rifle Scopes - Custom Ti Hardware for Spuhr Mount

*UPDATE* F/S Thread: https://www.snipershide.com/shooting/threads/custom-titanium-hardware-for-spuhr-mounts.7170272/ Hi all, I am in the process of building a new hunting rifle, and will be using Titanium hardware through out as I am neurotic and rusting hardware drives me insane. I also...

The screws (US Made) and cross bolts (UK Made) are Grade 5 Ti-Al6-V4 (titanium) with rolled threads. Because the Spuhr mount does not use hardware in sizes for the rings that are readily available in titanium, I turn these down on our lathe. Additionally, I decided to incorporate a flanged bolt for the cross bolts instead of the standard bolt and washer.

Benefits of this hardware are:

- Complete corrosion resistance

- Lighter weight

- Much deeper bit depth in the screw head

- Calculated to use the same lubricated torque specs as your standard hardware. A thread locker, lubricant, or Anti-seize should be used same as your steel hardware which comes from the factory with a dry film lube applied.

- More consistent pre-load. Because titanium is of a higher yield strength and lower Youngs Modulus compared to the steel in question, it will absorb more displacement (can elongate more, think of the screw as a spring) without the pre load changing. Pre load will vary under stress in any fastener, but far less in titanium compared to steel. Here that means less change in preload or opportunity for loosening as a result of recoil or vibration.

I have a number of people interested but would like to do a run of at least 20 sets to start. If you are interested, please post the following:

- Spuhr Mount Model #

- Number of sets

- Required extra hardware for attachments, spares, etc.

Pricing will start at $100 Shipped to your door for a set of 12x ring screws and 4x cross bolts. I will of course modify down for QD sets, sets with less ring screws, etc. and up for spares, accessories, etc. I am also happy to work with someone on developing a hunting mount set, your hardware will be free.

Please reach out with any questions. Thank you for your time and interest.

- Andrew

Last edited: