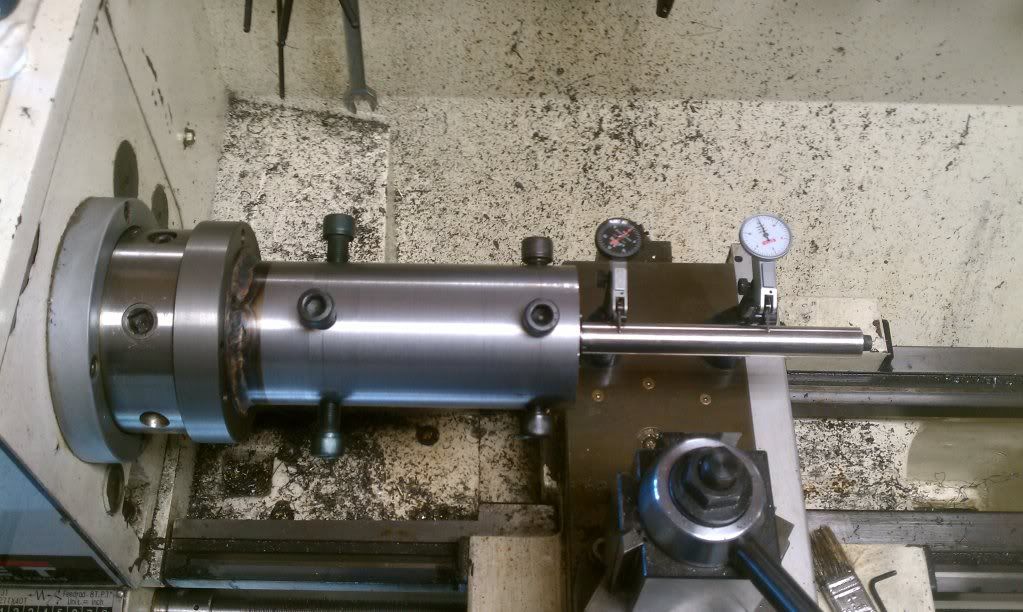

Re: D1-4 mounted directly to action jig?

I have a spare new back plate that I was thinking of doing the same thing with. I have Mig welding equipment but not Tig, would this be ok to do with Mig. The weld could be cleaned up once re mounted on the lathe.

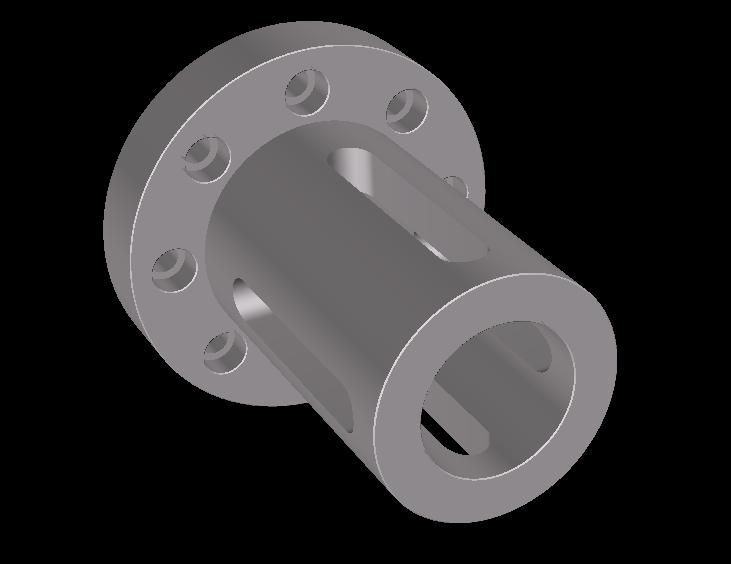

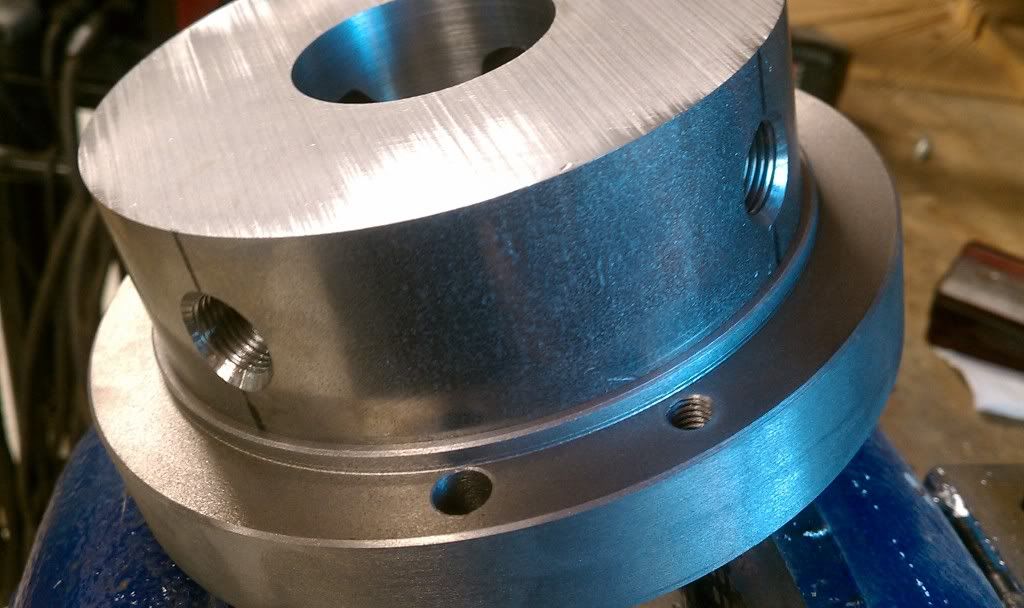

When I got my spider made to thread rifles for sound moderators, I went to the local machine shop, I gave them my drawing and dimensions. When I came back a day later to pick it up, I was not a happy camper.

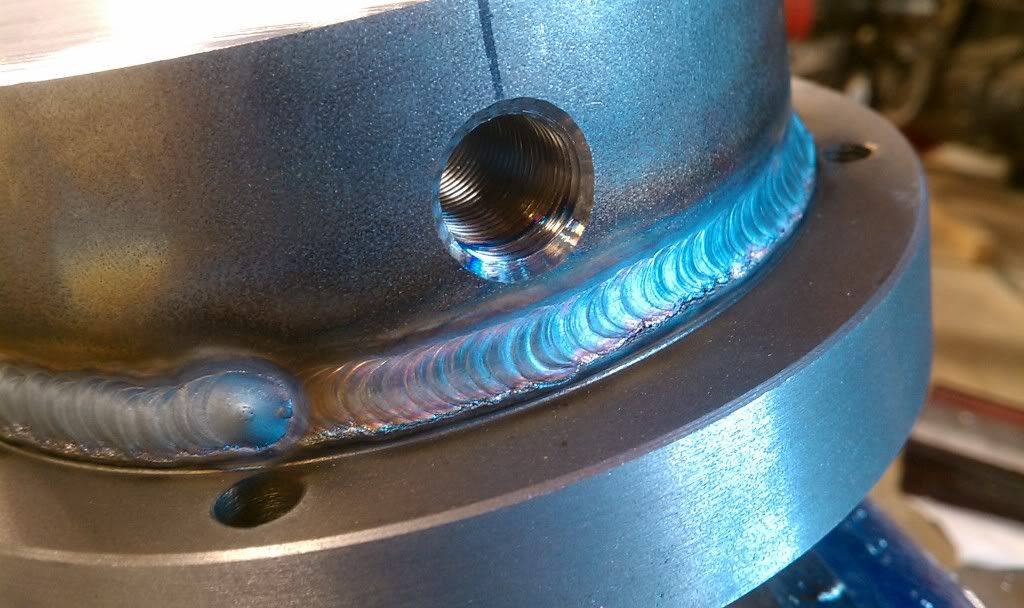

The screws that were drilled and tapped in the spider were so crooked that not one of them were on the same line or would have met each other if screwed all the way in.

I called the Foreman over and told him I was not accepting such shoddy work. Having never used a mill before, I am sure I could have lined the holes up better than a 40 years experienced machinist.

The Foreman told me that he had refused to train a young apprentice unless they gave him more money. They said no to the more money, so he decided that he would be a smart bustard and not give a darn about his work quality.

I told my father in law about this episode. when I told him the machinists name he looked at me and said, I trained that guy when he was an apprentice.