Re: Design Critique Please

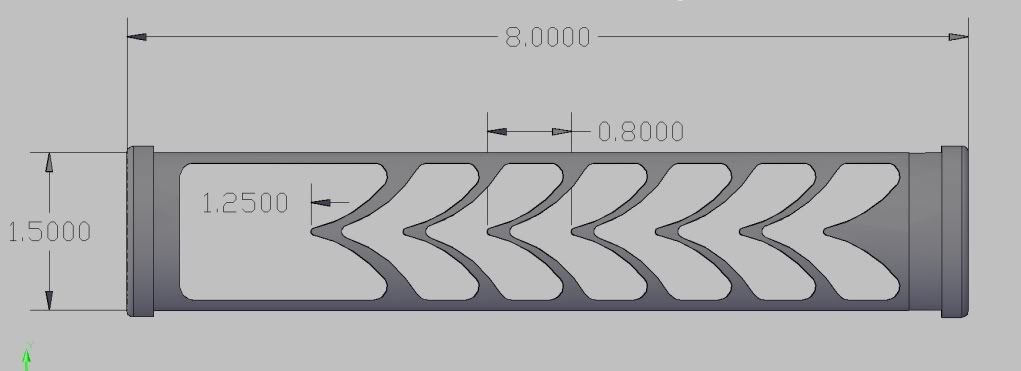

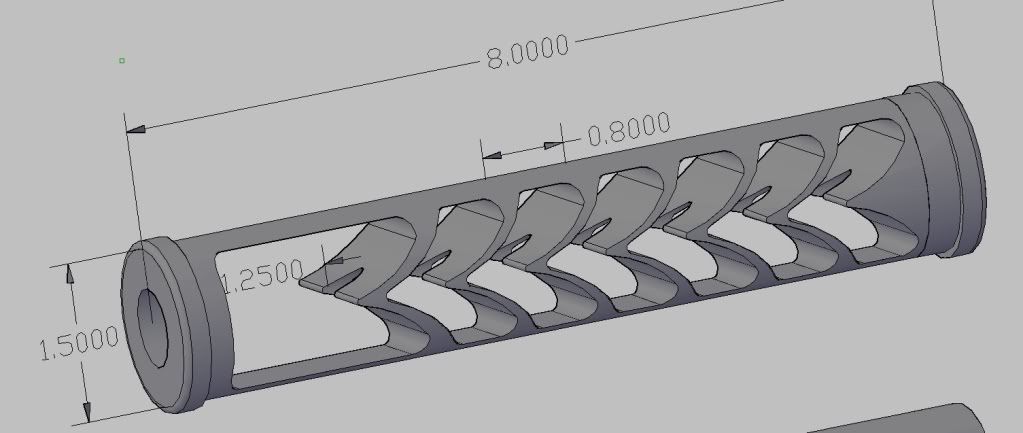

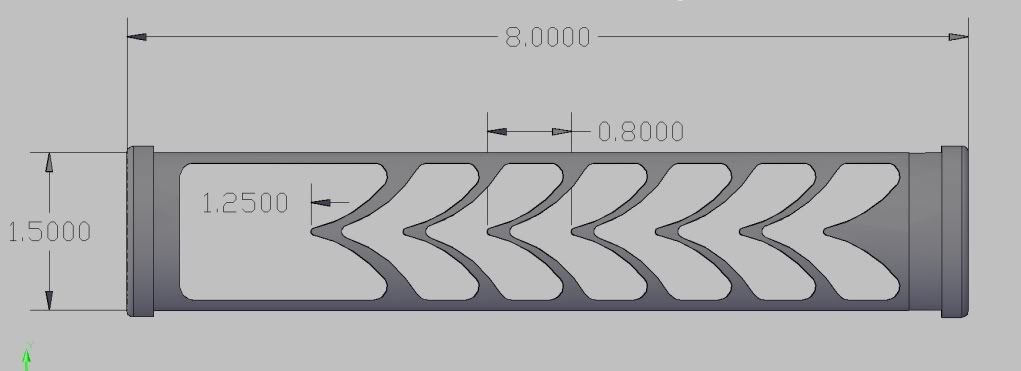

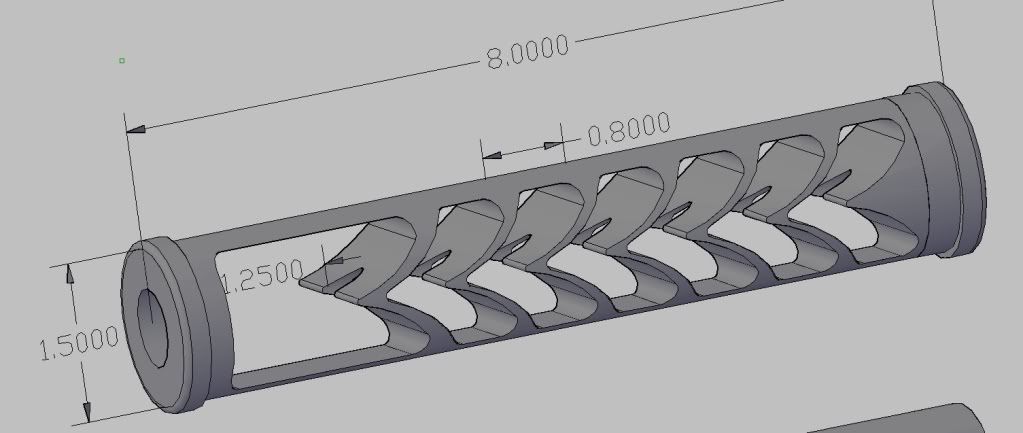

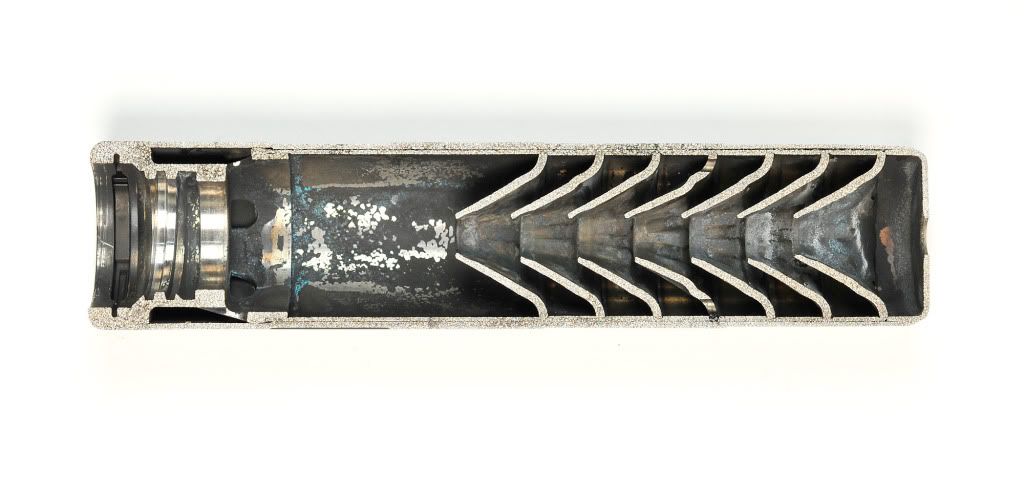

You're going to want more than .5" of threads on that side (.630 would be good [you don't want threads in the blast chamber getting fouled and them having to wear on the suppressor every time you take it off]).

The shaped solid baffle up front is just a waste of volume and weight. I'd move the baffling forward to close that chamber space a bit (.25"?), because the baffles further out front will be more efficient, and make the front of that chamber flat and parallel with the front of the muzzle.

Strength might be gained by adopting a .1875" thick, flat blast baffle located at the same 1.25" spacing (where the 1.25" dimension is) with 4 large (.25x.25" depth of cut) end mill or ball end mill cut "ports" ~.1" off the vanes running the length of the sides. <this way instead of a baffle shape that wants to flex inward on firing- with no supporting members, you then have a shape that doesn't want to flex so you gain a lot of strength where the pressure is highest.

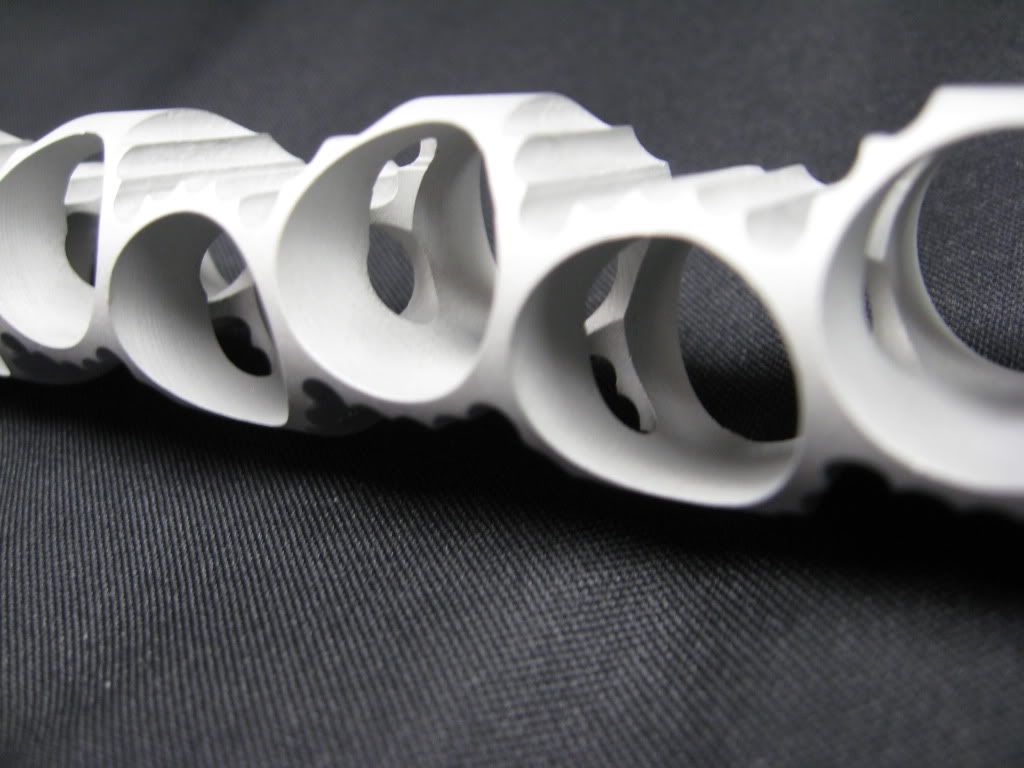

The thicker geometry of the current blast baffle might make sense for the second baffle. (this more for supersonic .300BLK on short barrels, or .308 use than for subsonic .300 BLK which is more like 9mm). The second baffle could nearly touch the flat baffle- so whatever the thickness of the cutting tool is should be fine.

You might also find that it performs better with 2 more baffles- closing spacing to something like .5".