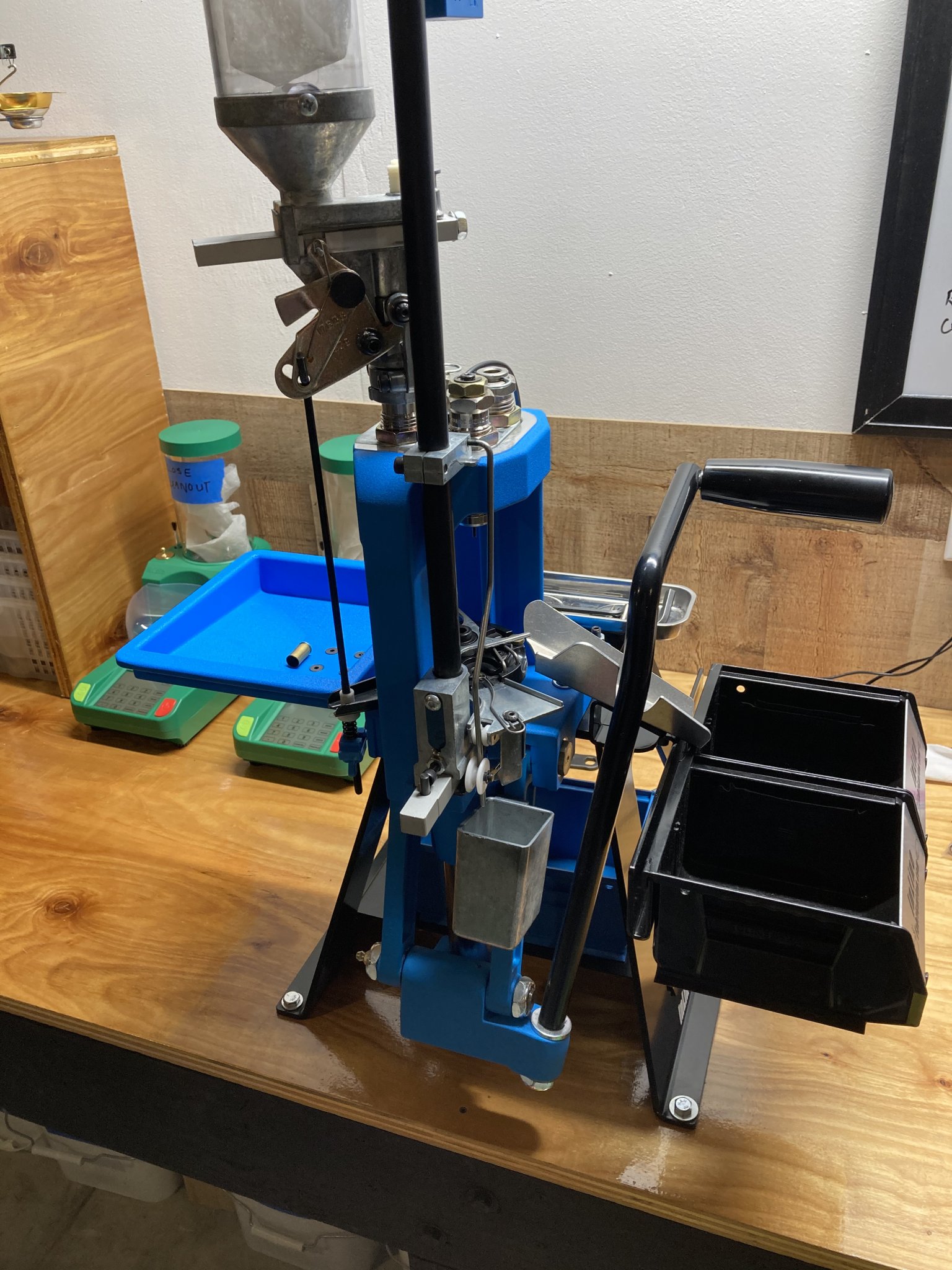

I purchased a Dillon 550C for my wife to give me for Christmas. I load a variety of 6 and 6.5mm cartridges with a Co-Ax, FX-Auto throw/trickler, Redding dies, annealer, nice equipment. This is strictly for accurate rifle ammo. My goal is to have the same quality but speed up the process. I have read and watched videos and realize there are numerous extras/improvements to be had. Where should I spend my money? What accessories will help with speed and accuracy? I plan on dropping powder from my FX scale and running 2 tool heads per cartridge. One for brass prep and one for loading. I have seen fancy tool heads, bearings, Inline Fab and Area419 stuff. Sort of overwhelming and need help.

- Thread starter northshorelumber

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Strong mount, bullet tray, roller handle, LED lights are the main upgrades I've got on my 550.

For tool heads I like the flat top CNC heads and use O-rings to float the dies, the o-rings sit nicer on a flat top toolhead compared to the Dillon one. I like being able to tweak dies on the fly to adjust sizing. Haven't felt the need to mess with the screw locking toolheads or the ones with pinned lock rings (seem like they'd be more work to swap and adjust).

Get your primer seating depth dialed in and then prime on the 550, that's one of the big time savers of progressive precision loading.

Lots of funnel options. Area 419 funnels look nice, I am just running a home-modified plastic MTM funnel that was $15.

If you are running Redding dies (I assume bushing dies) strongly consider going to a standard full length sizing die (with no expander ball internals) followed by a sizing mandrel die using a "turning" mandrel for 0.002 neck tension.

Read up on the Scott Harris article about progressive precision loading on a 550, lots of good info there. Many good threads here on the forum as well.

For tool heads I like the flat top CNC heads and use O-rings to float the dies, the o-rings sit nicer on a flat top toolhead compared to the Dillon one. I like being able to tweak dies on the fly to adjust sizing. Haven't felt the need to mess with the screw locking toolheads or the ones with pinned lock rings (seem like they'd be more work to swap and adjust).

Get your primer seating depth dialed in and then prime on the 550, that's one of the big time savers of progressive precision loading.

Lots of funnel options. Area 419 funnels look nice, I am just running a home-modified plastic MTM funnel that was $15.

If you are running Redding dies (I assume bushing dies) strongly consider going to a standard full length sizing die (with no expander ball internals) followed by a sizing mandrel die using a "turning" mandrel for 0.002 neck tension.

Read up on the Scott Harris article about progressive precision loading on a 550, lots of good info there. Many good threads here on the forum as well.

Get the kit.

For the powder drop, the Area 419 funnel and and adapter is the Cadillac option. You will also need the AT 500 powder die:

www.dillonprecision.com

www.dillonprecision.com

For the powder drop, the Area 419 funnel and and adapter is the Cadillac option. You will also need the AT 500 powder die:

AT 500 Powder Die (16629): Reloading: Reloader Dies

AT 500 Powder Die (16629): Reloading: Reloader Dies

550 Primer Track Bearing

550 Primer Track Bearing for Dillon Precision RL 550 reloading press.

www.uniquetek.com

If you are going to prime on it, this is the best upgrade I have done. The coating just switched from NP3 to Nicklon, but I am assuming that it is basically the same thing. Supports the primer bar better, allows you to put a little more tension on the bottom screws without binding, so you can get more consistent primer depth. Cheap. I had to replace my first one, which was no coated but dry lubed, after a few years, but the new one seems not to be wearing at all.

The Turbo bearing is good too, but you have to make sure to get the longer bolt. It isn't necessary, but the press runs a little slicker with it.

As far as throwing powder, it all really depends on what is good enough for you. You can get the Johnson Quick Measure with the progressive adapter, and reasonably throw within .05 with 4064 and 4350. For me that is good enough, and I save the tedium of weighing charges for powders that I can't deal with otherwise. .05 is my cutoff for that. If you are going to weigh each one, might as well go with two autotrickler set ups.

With some powders you can even use the Dillon measure. I calibrated a micrometer bar with Staball and my SD in powder drop was .03 grains, which again, is good enough for me. I tend to try to do things the easiest way, and the deal with one step more annoying each time the easier way doesn't quite work.

Last edited:

LED kit, strong mount, and about eleventyone tool heads would be my first purchase.

Also, go ahead and buy your second one now that way you have one set up for large primer and one for small.

Also, go ahead and buy your second one now that way you have one set up for large primer and one for small.

Thanks for the recommendations. Any more suggestions?

Don’t try to load your favorite recipes right off. You’re gonna be frustrated getting all the primer and powder timing sorted out for about 150-200 rounds and you’ll be frustrated and lose some powder and primers. So just start with some plinker pistol ammo or other straight wall, then some plain Jane rifle ammo. Fear not, once it’s running, it really runs.Thanks for the recommendations. Any more suggestions?

Primers and powder come to mind....

Strong Mount. The bullet holder attached to the strong mount is a very nice addition.

If you are even thinking about loading both large and small primers, getting two is 550’s works much better. Its not impossible to change out the primer system but not having two makes the entire process much quicker and less worrisome.

Next thing to consider is sticker shock. Have a hard time finding a more versatile reloading system. Getting there requires big bucks. Over $200 per complete caliber set up at current prices. (including tool head, powder throw and caliber conversion but not dies.) I have right at ten that I have collected through the years. Scares me as to how much they now cost.

I use my large primer 550 to load LRP 6.5 CM rounds. First prime and size, remove case from shellplate put casein case block next to RCBS manual powder throw, throw charge and trickle to weight, pour powder into case. Move case back to shellplate and advance two spaces, put new case in shellplate under sizing die, put bullet in charged case, Size/prime case and seat bullet. Time saver is doing two operations at same time.

I have actually loaded using the Dillon Powder throw. It works, accuracy was degraded slightly (might have been me) but I hate chasing powder charges, and throwing a charge then weighting and trickle to exact weight leads to more confidence.

For my contest rifle, using small rifle primer cases I use both of my single stage presses, one to size one to seat, and use an RCBS primer tool to prime cases. But I also double clean these cases, once before I size and again after sizing to remove lube. Could utilize my small primer 550, but since I have the single stage presses, and it would cost to purchase the shell plates/tool heads/stands/ or be darned inconvenient to move everything needed from one press to another, I just use the single stage.

When I shot IHMSA. My main money gun was a custom XP-100 in 7 TCU. Ran it straight on the Dillon. Checked charge on every fifth case, shot a whole bunch of perfect scores. Never underestimate a plain old Dillion 550.

If you are even thinking about loading both large and small primers, getting two is 550’s works much better. Its not impossible to change out the primer system but not having two makes the entire process much quicker and less worrisome.

Next thing to consider is sticker shock. Have a hard time finding a more versatile reloading system. Getting there requires big bucks. Over $200 per complete caliber set up at current prices. (including tool head, powder throw and caliber conversion but not dies.) I have right at ten that I have collected through the years. Scares me as to how much they now cost.

I use my large primer 550 to load LRP 6.5 CM rounds. First prime and size, remove case from shellplate put casein case block next to RCBS manual powder throw, throw charge and trickle to weight, pour powder into case. Move case back to shellplate and advance two spaces, put new case in shellplate under sizing die, put bullet in charged case, Size/prime case and seat bullet. Time saver is doing two operations at same time.

I have actually loaded using the Dillon Powder throw. It works, accuracy was degraded slightly (might have been me) but I hate chasing powder charges, and throwing a charge then weighting and trickle to exact weight leads to more confidence.

For my contest rifle, using small rifle primer cases I use both of my single stage presses, one to size one to seat, and use an RCBS primer tool to prime cases. But I also double clean these cases, once before I size and again after sizing to remove lube. Could utilize my small primer 550, but since I have the single stage presses, and it would cost to purchase the shell plates/tool heads/stands/ or be darned inconvenient to move everything needed from one press to another, I just use the single stage.

When I shot IHMSA. My main money gun was a custom XP-100 in 7 TCU. Ran it straight on the Dillon. Checked charge on every fifth case, shot a whole bunch of perfect scores. Never underestimate a plain old Dillion 550.

Get the kit.

For the powder drop, the Area 419 funnel and and adapter is the Cadillac option. You will also need the AT 500 powder die:

AT 500 Powder Die (16629): Reloading: Reloader Dies

AT 500 Powder Die (16629): Reloading: Reloader Dieswww.dillonprecision.com

This actually isn't true anymore. You use the standard drop die now with the 419 setup. At least that's what I ended up with after trying the at die and having it not fit. You need the standard through powder die, Dillon funnel, 419 adapter, probably drop tube to clear dies, and the 419 funnel. It's expensive, but works great.

This is good advice. On every progressive press the primer feed is the weak point. The 550 is probably the most simple, but two isn't a bad idea. I prefer the Inline Fab system, but definitely some mount.Strong Mount. The bullet holder attached to the strong mount is a very nice addition.

If you are even thinking about loading both large and small primers, getting two is 550’s works much better. Its not impossible to change out the primer system but not having two makes the entire process much quicker and less worrisome.

Next thing to consider is sticker shock. Have a hard time finding a more versatile reloading system. Getting there requires big bucks. Over $200 per complete caliber set up at current prices. (including tool head, powder throw and caliber conversion but not dies.) I have right at ten that I have collected through the years. Scares me as to how much they now cost.

I use my large primer 550 to load LRP 6.5 CM rounds. First prime and size, remove case from shellplate put casein case block next to RCBS manual powder throw, throw charge and trickle to weight, pour powder into case. Move case back to shellplate and advance two spaces, put new case in shellplate under sizing die, put bullet in charged case, Size/prime case and seat bullet. Time saver is doing two operations at same time.

I have actually loaded using the Dillon Powder throw. It works, accuracy was degraded slightly (might have been me) but I hate chasing powder charges, and throwing a charge then weighting and trickle to exact weight leads to more confidence.

For my contest rifle, using small rifle primer cases I use both of my single stage presses, one to size one to seat, and use an RCBS primer tool to prime cases. But I also double clean these cases, once before I size and again after sizing to remove lube. Could utilize my small primer 550, but since I have the single stage presses, and it would cost to purchase the shell plates/tool heads/stands/ or be darned inconvenient to move everything needed from one press to another, I just use the single stage.

When I shot IHMSA. My main money gun was a custom XP-100 in 7 TCU. Ran it straight on the Dillon. Checked charge on every fifth case, shot a whole bunch of perfect scores. Never underestimate a plain old Dillion 550.

As far as powder throw, my rule is to start with the Dillon throw, and if it gives me what I need, I am done. If it doesn't, I go more and more complicated until I arrive at the Autotrickler.

I’ve settle on the Inline fab mount, handle, as well as their light kit and bullet bins. I run Armonov toolheads for my precision stuff. I think they are really nice but cannot tell you wether they make a difference or not.

As far as powder funnel I started with the $6 Dillon funnel and well I’ve seen no need to change it yet. I just recently swapped back to my 9mm toolhead.

As far as powder funnel I started with the $6 Dillon funnel and well I’ve seen no need to change it yet. I just recently swapped back to my 9mm toolhead.

I have outfitted my 550 with:

If your focused on strictly performance enhancements go with the locking tool heads, turbo bearing combo, and primer track bearing in that order. With all these extras my 550 makes ammo that is just as concentric as my Forster Co-Ax, but with all the advantages of a progressive press.

- Inline Fabrication ultramount quick change mount

- Inline Fab roller grip

- Inline Fab bin system (it's a pair for input and output)

- Armanov locking tool heads and floating lock rings

- Area 419 powder funnel and drop tube (I use off press powder throwers for my rifle cartridges)

- UniqueTek primer track bearing

- UniqueTek custom powder funnels (9mm and 10mm). The dillon funnels stuck too much in clean brass and it was a pain. These stuck less but were still irritating so I had a local machine shop DLC coat the funnels and they are now fantastic.

- UniqueTek micrometer powder bar. This made messing around with the powder thrower much easier.

- UniqueTek turbo bearing and extended shellplate bolt

If your focused on strictly performance enhancements go with the locking tool heads, turbo bearing combo, and primer track bearing in that order. With all these extras my 550 makes ammo that is just as concentric as my Forster Co-Ax, but with all the advantages of a progressive press.

The Scott Harris article was very informative and I already have a mandrel setup plus ordered honed Forster FL sizers. Could you expand on using an O-ring to float your dies. Are you talking about regular rubber hardware store O-rings? Are the O-rings placed between the die lock ring and the top of the toolheads? How much compression is there on the O-ring, if the placement is as I described. My only other press is a Co-Ax so I have never screwed down a die before. Thanks for your help, BobStrong mount, bullet tray, roller handle, LED lights are the main upgrades I've got on my 550.

For tool heads I like the flat top CNC heads and use O-rings to float the dies, the o-rings sit nicer on a flat top toolhead compared to the Dillon one. I like being able to tweak dies on the fly to adjust sizing. Haven't felt the need to mess with the screw locking toolheads or the ones with pinned lock rings (seem like they'd be more work to swap and adjust).

Get your primer seating depth dialed in and then prime on the 550, that's one of the big time savers of progressive precision loading.

Lots of funnel options. Area 419 funnels look nice, I am just running a home-modified plastic MTM funnel that was $15.

If you are running Redding dies (I assume bushing dies) strongly consider going to a standard full length sizing die (with no expander ball internals) followed by a sizing mandrel die using a "turning" mandrel for 0.002 neck tension.

Read up on the Scott Harris article about progressive precision loading on a 550, lots of good info there. Many good threads here on the forum as well.

You should check out the SSI Alpha funnels. Honestly, they are one of the best products of any kind I've come across. I definitely endorse all of the other choices here. And it isn't that the Uniquetek funnels are bad, the SSI funnels are just one of those perfect products.I have outfitted my 550 with:

- Inline Fabrication ultramount quick change mount

- Inline Fab roller grip

- Inline Fab bin system (it's a pair for input and output)

- Armanov locking tool heads and floating lock rings

- Area 419 powder funnel and drop tube (I use off press powder throwers for my rifle cartridges)

- UniqueTek primer track bearing

- UniqueTek custom powder funnels (9mm and 10mm). The dillon funnels stuck too much in clean brass and it was a pain. These stuck less but were still irritating so I had a local machine shop DLC coat the funnels and they are now fantastic.

- UniqueTek micrometer powder bar. This made messing around with the powder thrower much easier.

- UniqueTek turbo bearing and extended shellplate bolt

If your focused on strictly performance enhancements go with the locking tool heads, turbo bearing combo, and primer track bearing in that order. With all these extras my 550 makes ammo that is just as concentric as my Forster Co-Ax, but with all the advantages of a progressive press.

I’m having trouble picturing how the various parts fit together for me to drop the powder into the case (I will be weighing powder on my FX scale). Screw the standard through die into the toolhead? Then insert the caliber specific Dillon funnel that comes in the caliber conversion kit? Then it sound like I need three Area 419 parts that connect to each other, maybe screw together? I’m guessing there is a 419 adapter that interfaces with the Dillon funnel, next a drop tube for height, and finally the standard metal 419 funnel on top? Is the 419 set up universal to all calibers? I have the Dillon parts but not the 419 parts yet. I wanted to make sure I order correctly. Thanks for the help, BobThis actually isn't true anymore. You use the standard drop die now with the 419 setup. At least that's what I ended up with after trying the at die and having it not fit. You need the standard through powder die, Dillon funnel, 419 adapter, probably drop tube to clear dies, and the 419 funnel. It's expensive, but works great.

I checked out the SSI Alpha funnels but only found ones for pistol calibers. I only load rifle rounds, am I missing something?You should check out the SSI Alpha funnels. Honestly, they are one of the best products of any kind I've come across. I definitely endorse all of the other choices here. And it isn't that the Uniquetek funnels are bad, the SSI funnels are just one of those perfect products.

It looks like I will be spending as much, if not more, on upgrades as I have on the basic press. Toolheads, mount, bearing, light, etc. Just want to spend wisely. Thanks

Rifle funnels are not really important. They just sit in the powder die and their only purpose is to be the right caliber and length to make the system work. Pistol funnels are almost the heart of the pistol loading system. They expand the case mouth to take the bullet, and also dispense the powder. The dispensing part is easy. The getting just the right geometry and slickness to expand and not spill powder everywhere on the way up is the hard part.I checked out the SSI Alpha funnels but only found ones for pistol calibers. I only load rifle rounds, am I missing something?

To answer your question on how it works with the area 419 funnel, you drop your Dillon rifle funnel into the powder die, which you only have screwed in a couple of turns, then connect the area 419 funnel to the top of the powder die. Then put a case in the powder station and lower the handle. From there you screw down the powder die until the Dillon funnel just touches the area 419 funnel. Lower the handle, turn in the powder die 1/8 turn and lock it down. This way when you lower the handle the two funnels have a solid connection and all your powder drops in.

Don't forget level 10 innovations. This is cheap and good

lvl10i.com

lvl10i.com

Shellplate Bearing kit w/ Modified Sprocket for Dillon 550

Dillon 550, shellplate, bearing, ammo, reloading, powder, primers

The Scott Harris article was very informative and I already have a mandrel setup plus ordered honed Forster FL sizers. Could you expand on using an O-ring to float your dies. Are you talking about regular rubber hardware store O-rings? Are the O-rings placed between the die lock ring and the top of the toolheads? How much compression is there on the O-ring, if the placement is as I described. My only other press is a Co-Ax so I have never screwed down a die before. Thanks for your help, Bob

Yes, hardware store o-rings, there just to provide some crush resistance and float. There seems to be a good working range for the amount of crush on the o-ring, starting with snug hand tight to all the way forceful hand tight. You'll need to rough adjust the lock ring to get the die within that range, then once it's there all your fine tuning is done just by adding or removing a bit of crush on the o-ring. You can adjust sizing on the fly by as much as 3-4 thousandths of shoulder bump without ever having to adjust the lock ring position and the die doesn't move or back out when sizing.

Never seen that before, ordering now!Don't forget level 10 innovations. This is cheap and good

Shellplate Bearing kit w/ Modified Sprocket for Dillon 550

Dillon 550, shellplate, bearing, ammo, reloading, powder, primerslvl10i.com

One other upgrade comes to mind. If you use the Dillon powder measures, the amount of tension you get on the failsafe rod spring is really important for throw consistency. The little blue nut is a pain in the ass, and you end up not adjusting it as often as necessary. Replacing it with the Entirely Crimson speed nut is a very good idea, saves time, makes it easier to switch out the white bushing when it cracks, and it is a cheap upgrade. If you are only measuring and funneling in powder for precision rounds it is not necessary.

Another thing, this one for 1050s, is to tap the shellplate retainer from the sides and use three brass set screws to hold it down rather than to use the top screws with the white washers. It makes it a lot easier if you need to get up under the shellplate to clean something as screw access is easier, and you never have to worry about clearance if you are using a roller bearing.

I've got most of the recommended add-ons on my two-three 550s..

Another would be Dramworx Pyrex powder reservoirs for Dillon powder measures. Double-base powders with a high nitroglycerin content (Bullseye, VV N540) seem to darken the factory powder reservoirs if you leave them in for any length of time. Pyrex seems to stain less.

Factory powder reservoir (covered by warranty, so there's that) on left:

Another would be Dramworx Pyrex powder reservoirs for Dillon powder measures. Double-base powders with a high nitroglycerin content (Bullseye, VV N540) seem to darken the factory powder reservoirs if you leave them in for any length of time. Pyrex seems to stain less.

Factory powder reservoir (covered by warranty, so there's that) on left:

For the love of god get the InLine Fabrication Quick Change ultra mount and not the strongmount. It’s the same price except it works with all your presses, and you can swap em out in 10 seconds.

agreed. Got the quick change mounts on everything, including a big vise. Heck, even have one setup with a bike work stand so I can work on my bicycles at the workbench. Can't recommend them enough.For the love of god get the InLine Fabrication Quick Change ultra mount and not the strongmount. It’s the same price except it works with all your presses, and you can swap em out in 10 seconds.

Dang it. Don’t be dragging those poor bikes into your shop. Build a dedicated bike shop. It works so much betterHeck, even have one setup with a bike work stand so I can work on my bicycles at the workbench. Can't recommend them enough.

(Now the rest of the story). I built and repaired and serviced bikes on a make shift bike stand working from my vice in the big shop. For multiple reasons (Thank you obama, Sarcasm intended) mainly we needed storage room in the big shop. This was when old mama sequestered multiple long serving members of our armed forces including our son. Having a dedicated shop to get some bikes out of our home, some bikes out of the big shop and all of the bicycle work/parts/supplies/dedicated tools moved out of the big shop was a definite plus. Plus (a little alliteration there) we did this entire project ourselves and it turned out to be a pretty nice shop. Picture below was virtually the day it was finished, we shored up the support blocks and have since built it a deck.

Getting back to the thread, I need to check out that mount. Really don’t need it but it might just work best for mounting my Orange Crush. If not that, I will need to modify my RCBS accessory plate which for me has been the bees knees of equipment on my reloading table.

love the improvement you have made. thanks for sharingI’ve settle on the Inline fab mount, handle, as well as their light kit and bullet bins. I run Armonov toolheads for my precision stuff. I think they are really nice but cannot tell you wether they make a difference or not.

As far as powder funnel I started with the $6 Dillon funnel and well I’ve seen no need to change it yet. I just recently swapped back to my 9mm toolhead.View attachment 7751793

Similar threads

- Replies

- 150

- Views

- 8K

Reloading Equipment SPF—Dillon Square Deal B Set up for .45 ACP

- Replies

- 2

- Views

- 567