More info on the Toolhead Stands can be found here.

www.northeastshooters.com

www.northeastshooters.com

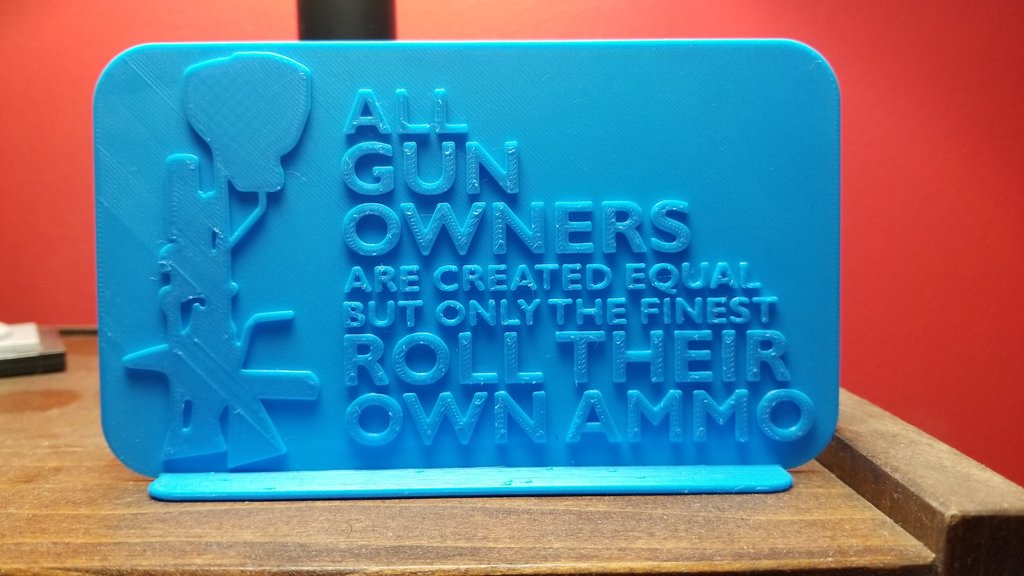

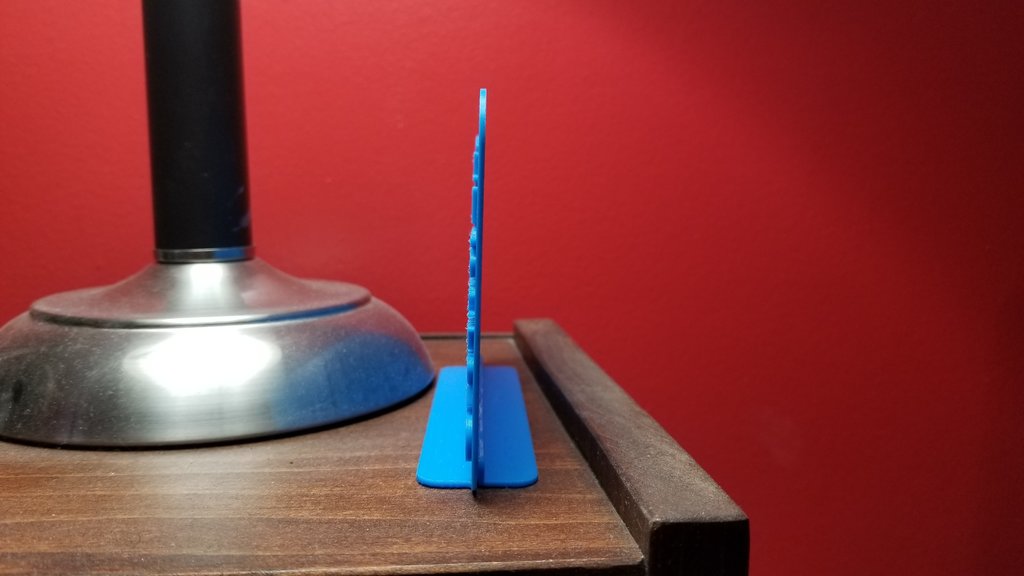

I can make this with the stand or flat, thoughts? Other Ideas?

Also been suggested, incorporate this into a Tool Head Stand.

Dillon Reloading Accessories

I've completed the Toolhead Stands 550/650/1050/SDB/Powder Measure They are available here. I'll be adding more items as they are developed. D5 Reloading

I can make this with the stand or flat, thoughts? Other Ideas?

Also been suggested, incorporate this into a Tool Head Stand.

Last edited: