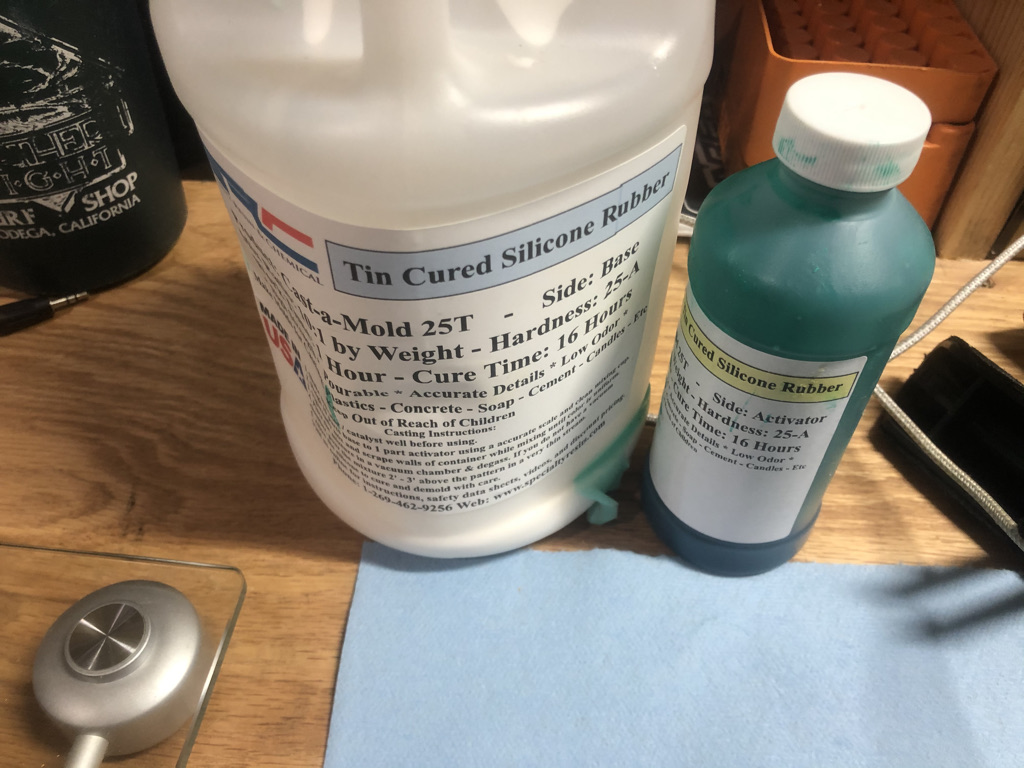

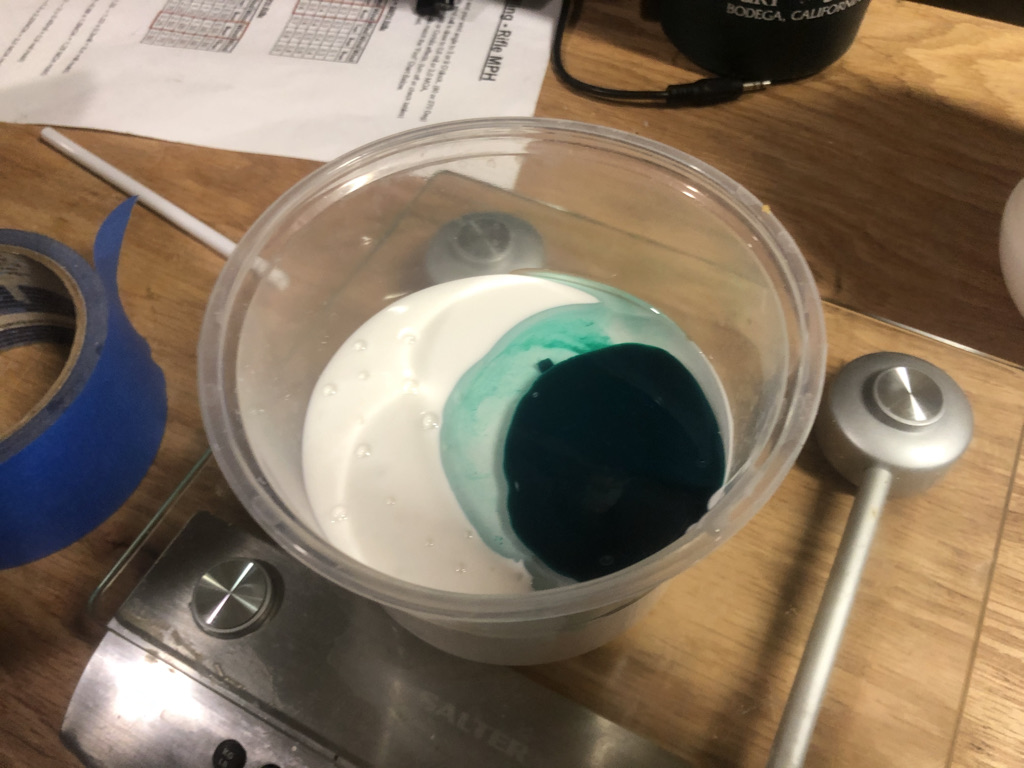

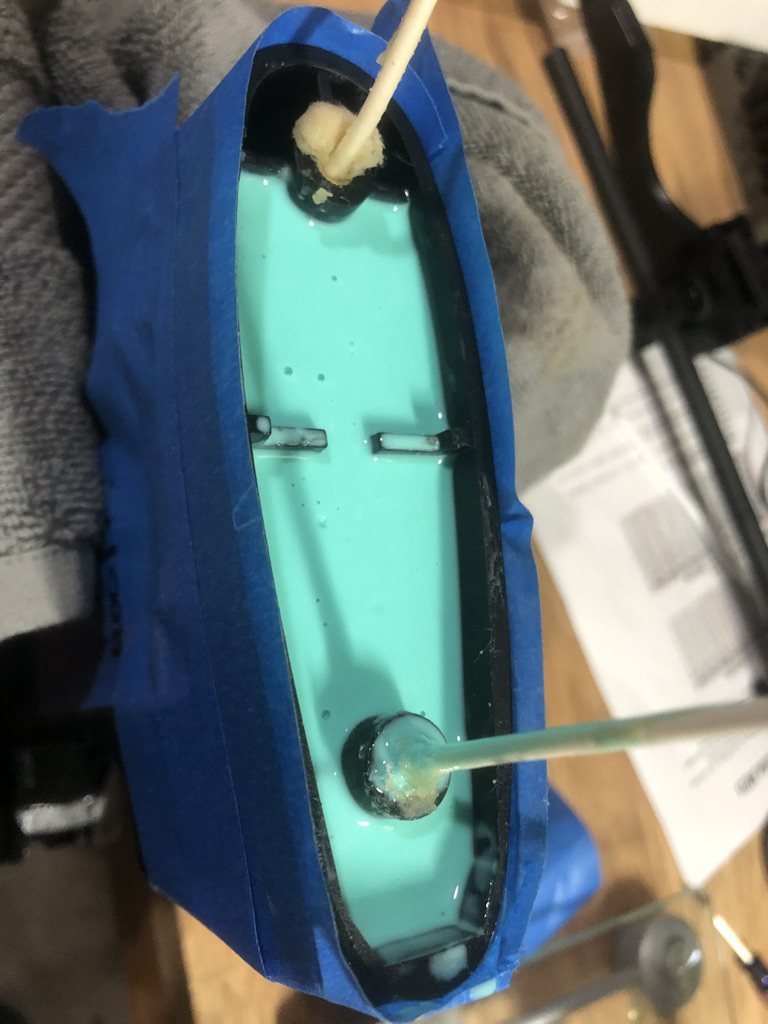

I had some 2 part catalyzed silicone for molds left over from a past project. My Howa 308 is pretty nose heavy in my Bravo, so I decided to fuck around and find out if this could be resolved. I liberally applied paste wax and Kroil to all compartments of the buttstock, butt hook area and handle. I mixed up the silicone and poured in the cavities (don't forget to tape the holes in the buttstock, found out the hard way!) and let it cure overnight.

- Thread starter Gregor.Samsa

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

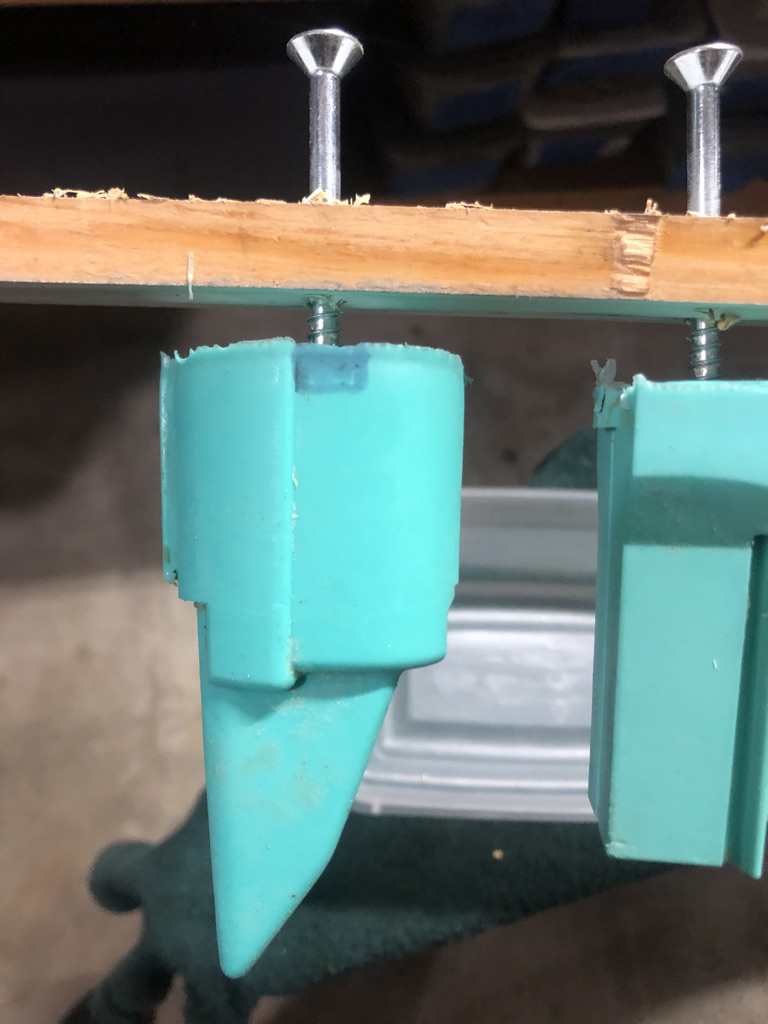

The cured silicone popped out without any drama. I screwed 1/4" wood screws through a few pieces of scrap wood to hold the silicone mold cores in the proper position in the plaster that I planned to use for the final mold. I underestimated the amount of plaster that I'd need and was able to scramble and find some paint cups to contain everything on time. Again, I left the plaster to cure overnight and was able to remove the silicone easily.

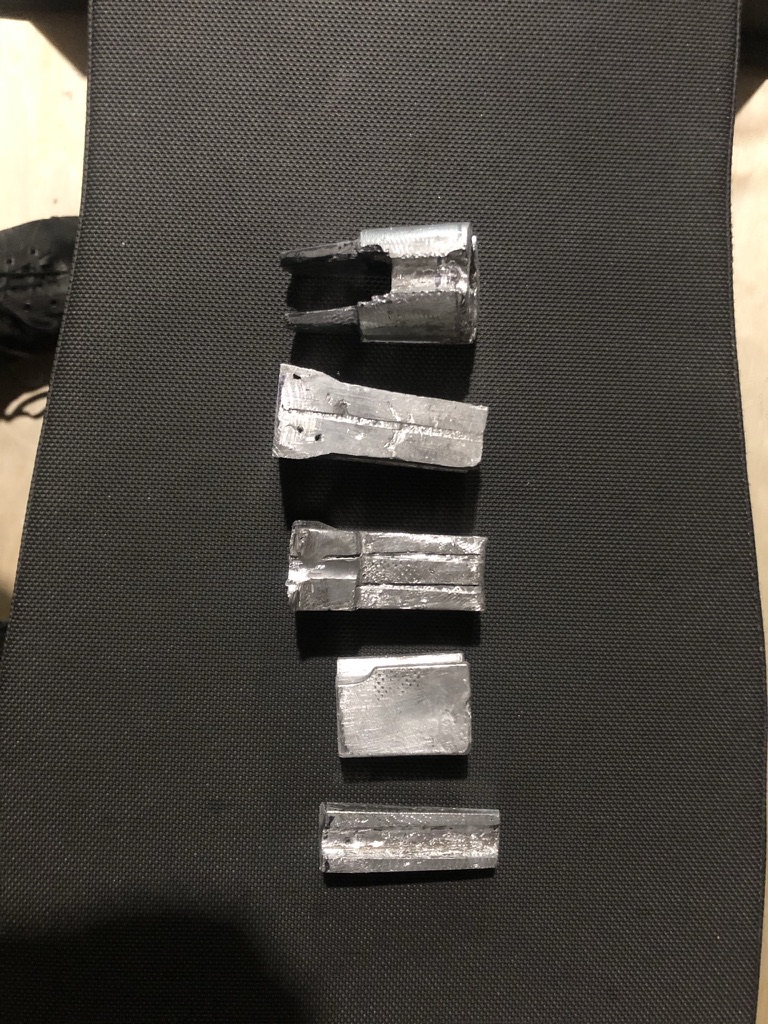

I frickin forgot to take photos of the plaster molds or any part of the lead casting lol, but essentially allowed the plaster to dry for about a week and a half. I melted some lead in an old pan on a camp stove with the help of a propane torch and then poured them into the mold cavities. I really underestimated the dry time / moisture content of the plaster and had the molten lead boil out the water in the plaster which resulted in a little porosity. As this is only serving as weight and not structural or aesthetic, I didn't sweat it. One thing that I failed to consider was the shrinkage of the plaster molds as they dried which resulted in the lead weights being slightly too large to fit in their respective cavities and necessitated some finessing with files. All said and done, the finished weights resulted in a total of 5 pounds, 5 ounces able to be added to the stock. I only wound up adding about half of that as the rifle became very tail heavy. I still have a little fine tuning with the weight distribution but overall am pretty happy with the results.

I think I'll try this agin doing a better job. I need to identify a better mold material than plaster that wont shrink or retain moisture.

Nice

I need to take a pic of the chunk of lead o made for one of the pockets in the forearm on my XLR element.

I need to take a pic of the chunk of lead o made for one of the pockets in the forearm on my XLR element.

If anyone wants to make a casting, I can ship out the silicone cores i made

Thanks for documenting that. I put a 30" 1.25" diameter barrel on my action and my Bravo is pretty nose-heavy too. Pretty heavy overall, really. I'll likely add some lead, but I was thinking of using lead shot with acraglass to make the weights stay in place.

I just made took a couple pieces of pine, drilled a hole in them with a boring bit (can’t remember the size, just measure the cavities). Poured in some melted wheelwright metal, and cut the blocks from around the slugs.

Wrapped them in cellophane to keep them from rattling.

I didn’t need much weight, but with the can and bipod, it was definitely nose heavy. Nowhere near as much now.

Nowhere near as fancy as y’all’s solutions, but you all will likely get more weight in the stock with your methods.

Wrapped them in cellophane to keep them from rattling.

I didn’t need much weight, but with the can and bipod, it was definitely nose heavy. Nowhere near as much now.

Nowhere near as fancy as y’all’s solutions, but you all will likely get more weight in the stock with your methods.

Honestly,Thanks for documenting that. I put a 30" 1.25" diameter barrel on my action and my Bravo is pretty nose-heavy too. Pretty heavy overall, really. I'll likely add some lead, but I was thinking of using lead shot with acraglass to make the weights stay in place.

I’d probably do that too. I just had the silicone and got my mind going. If I can find a mold material that doesn’t shrink or restrain water, it would have been pretty easy.

I love that you made the molds. I also would like to try sand casting of aluminum at some point, like David Gingery does in his series of books. He starts with sand casting, then uses the aluminum castings to make a lathe, a mill, a metal shaper.

I do t want to sell the weights themselves but would be glad to loan out the silicone cores for shipping costs.Would you sell the lead weights? Pretty slick. The forend would be easy to do a mold as well.

Thanks for posting up. Using the same silicone and casting lead shot in place might be an option too.

I've cast some myself .

I've cast some myself .

That looks great. What did you use for your mold? If I do this again, I want to use a material that doesn't shrink or retain moisture.Thanks for posting up. Using the same silicone and casting lead shot in place might be an option too.

I've cast some myself .

I've been thinking of doing something like this but I need more weight up front until I rebarrel.

Well done. I've thought about doing something similar to this. My current solution is I filled up all the voids with steel shot. Could add more weight using lead shot for sure, but steel was available. Only thing I don't like about my solution is you can hear the shot moving around once in a while, plus depending on what I'm shooting I like to take all the weight out and put it back in, your solution would make that a breeze. Another problem I have is the plate on the bottom of the grip does not hold enough upward pressure to keep the shot in the handle under recoil. I fixed that with a piece of tape for now but again I like the idea of a solid molded weight.

I think you could get around this by liberally spraying the cavities with kroil or rubbing with paste wax then returning the shot to the cavities and filling with epoxy resin. You should be able to remove from your stock no problem. I would probably go this route but I had the lead and the silicone.Well done. I've thought about doing something similar to this. My current solution is I filled up all the voids with steel shot. Could add more weight using lead shot for sure, but steel was available. Only thing I don't like about my solution is you can hear the shot moving around once in a while, plus depending on what I'm shooting I like to take all the weight out and put it back in, your solution would make that a breeze. Another problem I have is the plate on the bottom of the grip does not hold enough upward pressure to keep the shot in the handle under recoil. I fixed that with a piece of tape for now but again I like the idea of a solid molded weight.

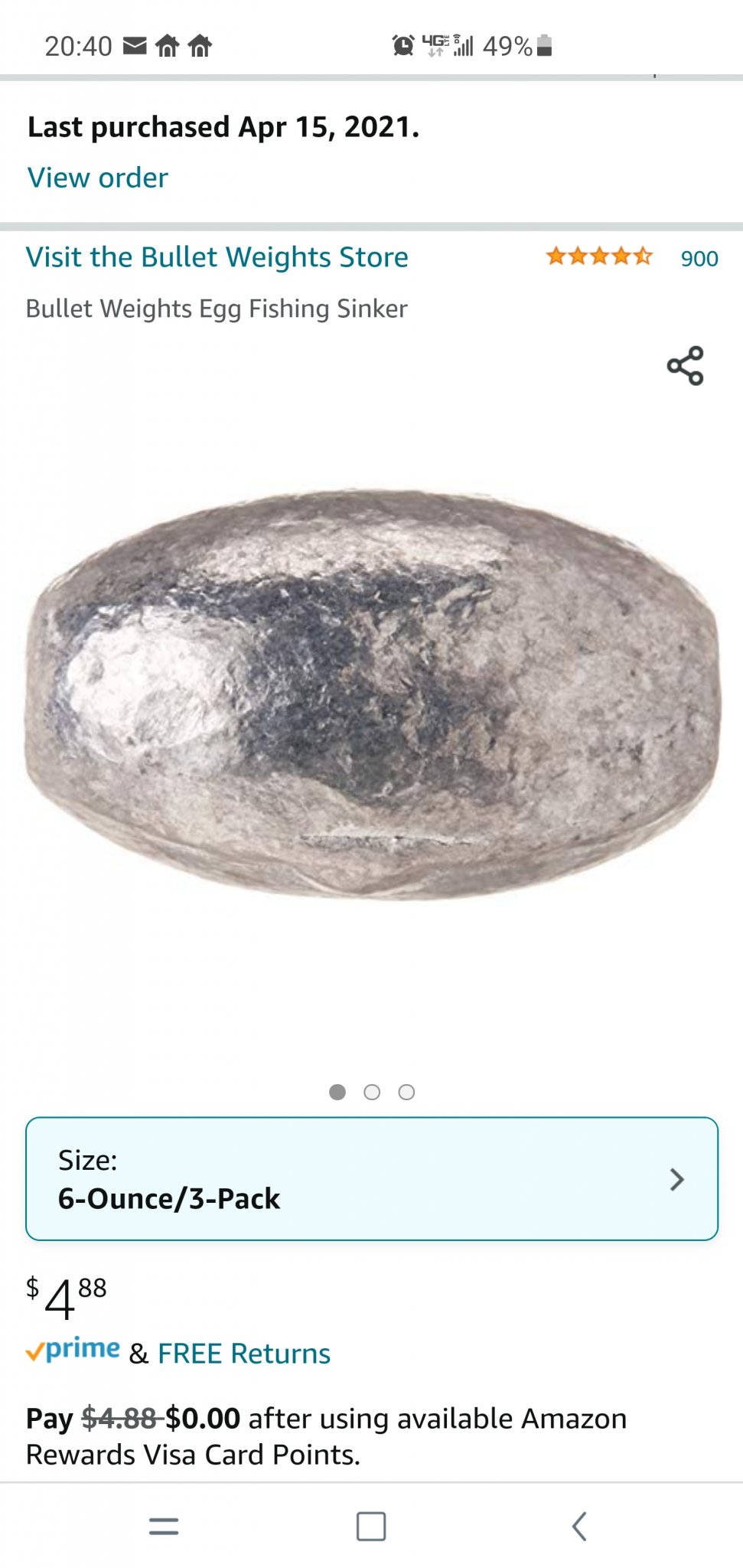

For just $5 on amazon...

I was able to add 18 ounces (over a pound) to the butt stock using these lead sinker weights.

Remove the LOP spacers from the butt and you can fit two 6oz eggs in there. Dremel the plastic if you need more space. Pack it in with latex gloves if you need.

One 6 ounce weight fits in the grip. Remove the bottom panel and put on in and pack with latex gloves.

I was also able to fit two more 6 ounce balls in the butt stock under the butt stock cover.

So...$10 and 10min added over 2lbs

I was able to add 18 ounces (over a pound) to the butt stock using these lead sinker weights.

Remove the LOP spacers from the butt and you can fit two 6oz eggs in there. Dremel the plastic if you need more space. Pack it in with latex gloves if you need.

One 6 ounce weight fits in the grip. Remove the bottom panel and put on in and pack with latex gloves.

I was also able to fit two more 6 ounce balls in the butt stock under the butt stock cover.

So...$10 and 10min added over 2lbs

I realize this thread is a few months old but I was inspired by this to come up with something I could do to build some weights that will go in and out of the butt stock easily. I ended up machining some weights from steel. The down side compared to your lead weights is they don't fill the voids entirely due to me not wanting to machine crazy angles. Overall it adds about 3.5 pounds still, I could add another couple pounds by adding the butt plate spacers from Snyder to it as well, but I think 3.5 is plenty for my purposes. Just another idea if anyone has access to machining equipment.

Hi Guys,

I went a little bit of an easy way, although it is not filling the last bit, it is still putting a lot of lead into the stock.

I just got fine lead shot and mixed it with black silicone in a freezer bag. It requires little silicone to get a good sticky mix. Then stuffed the mixture into all the holes in the front and rear of the stock. If you like it removable you can just put cling film in the holes before filling. Worked well and required basically no tools and just 30 min work and 2 days drying time... and 30 min cleaning my hands

I went a little bit of an easy way, although it is not filling the last bit, it is still putting a lot of lead into the stock.

I just got fine lead shot and mixed it with black silicone in a freezer bag. It requires little silicone to get a good sticky mix. Then stuffed the mixture into all the holes in the front and rear of the stock. If you like it removable you can just put cling film in the holes before filling. Worked well and required basically no tools and just 30 min work and 2 days drying time... and 30 min cleaning my hands

Attachments

Last edited:

That's badass! i made the molds because I'm a caveman, this raises the bar for sure. Nice work!I realize this thread is a few months old but I was inspired by this to come up with something I could do to build some weights that will go in and out of the butt stock easily. I ended up machining some weights from steel. The down side compared to your lead weights is they don't fill the voids entirely due to me not wanting to machine crazy angles. Overall it adds about 3.5 pounds still, I could add another couple pounds by adding the butt plate spacers from Snyder to it as well, but I think 3.5 is plenty for my purposes. Just another idea if anyone has access to machining equipment.

View attachment 7730288View attachment 7730289View attachment 7730287View attachment 7730286

Killer idea!Hi Guys,

I went a little bit of an easy way, although it is not filling the last bit, it is still putting a lot of lead into the stock.

I just got fine lead shot and mixed it with black silicone in a freezer bag. It requires little silicone to get a good sticky mix. Then stuffed the mixture into all the holes in the front and rear of the stock. If you like it removable you can just put cling film in the holes before filling. Worked well and required basically no tools and just 30 min work and 2 days drying time... and 30 min cleaning my hands

Haha, well thanksThat's badass! i made the molds because I'm a caveman, this raises the bar for sure. Nice work!

Thanks guys,That's badass! i made the molds because I'm a caveman, this raises the bar for sure. Nice work!

I used to have a machine shop with everything to wish for and would have probably gone for a perfect mold back then too. Now I have no workshop and have to get a bit more creative for good solutions and I am happy to share them.

I would think this method would work with most stock/chassis.

It is also comparably easy to pry the weigths out with a screwdriver if you want it light again.

For just $5 on amazon...

I was able to add 18 ounces (over a pound) to the butt stock using these lead sinker weights.

Remove the LOP spacers from the butt and you can fit two 6oz eggs in there. Dremel the plastic if you need more space. Pack it in with latex gloves if you need.

One 6 ounce weight fits in the grip. Remove the bottom panel and put on in and pack with latex gloves.

I was also able to fit two more 6 ounce balls in the butt stock under the butt stock cover.

So...$10 and 10min added over 2lbs

View attachment 7631476

This is a great idea for cheap weight so I gave it a try and ordered the 6 ounce/3 pack. I'm not sure if your weights were actually 4 ounces or if the ones I got are just...big...but the 6 ounce weights I got were too large for everywhere except the grip. I was able to fit 2 behind the recoil pad and 1 on the bottom of the stock, but a considerable amount of hammering was required to shape them to fit. Not a big deal, but I thought I'd mention it in case anyone else wants to go this route. Thanks for the idea though because this was much cheaper than buying sinkers locally.

I went with as many 55grain .22 bullets as i could stuff in the back. Super lazy.

Similar threads

- Replies

- 30

- Views

- 4K

- Replies

- 0

- Views

- 557

- Replies

- 5

- Views

- 641