I am curious if anyone knows if leaving powder, say varget, in auto trickler or any powder thrower for a few days will let the powder pull moisture. Any harm in leaving in or should it be removed at end of each reloading???

- Thread starter mjwilcox38

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Powder should always be restored to a sealed container. Perhaps with a desiccant as well. I have read several articles, as well as more than a few posts here, discussing moisture contamination at length. Some people even advocated using only 1lb bottles to avoid ruining 8lb all at once.

Will powder exposed to moisture combust? Sure. The questionable provenance reloads my father bought 30 years ago also combusted. Will powder exposed to moisture combust in a stable predictable fashion conducive to precision? Doubtful.

Will powder exposed to moisture combust? Sure. The questionable provenance reloads my father bought 30 years ago also combusted. Will powder exposed to moisture combust in a stable predictable fashion conducive to precision? Doubtful.

What is the point of only using 1 pound bottles? I use 8 pounds often. I do keep the 8 pound jugs in temp control and pour into 1 pound bottle for use so it is easier to pour. Then when the 1 pound bottle gets low I refill with the 8 pound.Powder should always be restored to a sealed container. Perhaps with a desiccant as well. I have read several articles, as well as more than a few posts here, discussing moisture contamination at length. Some people even advocated using only 1lb bottles to avoid ruining 8lb all at once.

Will powder exposed to moisture combust? Sure. The questionable provenance reloads my father bought 30 years ago also combusted. Will powder exposed to moisture combust in a stable predictable fashion conducive to precision? Doubtful.

What happen?After mistakingly leaving Titegroup in a Chargemaster overnight, I learned to never leave powder in anything for any reason, ever.

It etches/melts into the plastic. I think it's the high nitro content. Theoretically wouldn't be a problem with a stick powder but I'm not risking it.What happen?

The gentlemen who suggested 1lb containers was buying sealed powder 1lb at a time. 1lb containers would mean the other 7lbs is not also exposed to moisture while not in use. If you are running through 8lbs quickly I am not sure it would matter.What is the point of only using 1 pound bottles? I use 8 pounds often. I do keep the 8 pound jugs in temp control and pour into 1 pound bottle for use so it is easier to pour. Then when the 1 pound bottle gets low I refill with the 8 pound.

Somewhere in the forums there is a long post complete with testing results to corroborate moisture effects. The fact that moisture has measurable, and often overlooked effects, is my main contribution to your question.

Thanks.The gentlemen who suggested 1lb containers was buying sealed powder 1lb at a time. 1lb containers would mean the other 7lbs is not also exposed to moisture while not in use. If you are running through 8lbs quickly I am not sure it would matter.

Somewhere in the forums there is a long post complete with testing results to corroborate moisture effects. The fact that moisture has measurable, and often overlooked effects, is my main contribution to your question.

I've read that most powder is packaged at around 50% RH.

Would powder stored at less than 50% RH lose moisture?

Powder stored in an unheated garage that is allowed to approach the atmospheric dew point (high RH)

likely sucks in moisture.

Do you reload when your reloading room is not CLOSE to 50% RH? Do you monitor it or just rely on your HVAC?

Would powder stored at less than 50% RH lose moisture?

Powder stored in an unheated garage that is allowed to approach the atmospheric dew point (high RH)

likely sucks in moisture.

Do you reload when your reloading room is not CLOSE to 50% RH? Do you monitor it or just rely on your HVAC?

moisture "gets through" plastic bottles and caps, they aren't magic barriers

in pharma, stability tests are performed for packaging moisture permeability and its effects on product / pills

product sits in controlled humidity and temperature controlled chamber (really nice refrigerator)

as can be imagined different materials, the thickness of material, cap liner material, and the torque of cap all have effects on the moisture barrier

additionally, most people who think throwing a few desiccants in the bottle have not researched what size desiccant is needed for that size bottle etc

using an old desiccant from an amazon t-shirt is useless as its already been exposed

desiccants usually come on a roll of 5-10,000 and are sitting in a nitrogen-purged cabinet on the inserting equipment once opened from the original packaging.

leave that roll out overnight in the open environment and they are virtually useless the next day when tested by QA pre check of the packaging line.

just food for thought

in pharma, stability tests are performed for packaging moisture permeability and its effects on product / pills

product sits in controlled humidity and temperature controlled chamber (really nice refrigerator)

as can be imagined different materials, the thickness of material, cap liner material, and the torque of cap all have effects on the moisture barrier

additionally, most people who think throwing a few desiccants in the bottle have not researched what size desiccant is needed for that size bottle etc

using an old desiccant from an amazon t-shirt is useless as its already been exposed

desiccants usually come on a roll of 5-10,000 and are sitting in a nitrogen-purged cabinet on the inserting equipment once opened from the original packaging.

leave that roll out overnight in the open environment and they are virtually useless the next day when tested by QA pre check of the packaging line.

just food for thought

Here's a paper on results from one person's testing:

chronoplotter.com

chronoplotter.com

How does humidity affect powder?

You may have heard about a relationship between humidity and bullet velocity either in a book, on a reloading forum, or from a crusty benchrest shooter right after saying they get better ES/SD̵…

chronoplotter.com

chronoplotter.com That happened to me too on my Chargemaster.It etches/melts into the plastic. I think it's the high nitro content. Theoretically wouldn't be a problem with a stick powder but I'm not risking it.

I also have a Lee Autodrum powder measure I use on another press. I leave Titegroup in it all the time. No etching, slight discoloration though, but might just be dirty. I haven't tried cleaning it off.

What happen?

It etches/melts into the plastic. I think it's the high nitro content.

I've read that most powder is packaged at around 50% RH.

Just curious, what "solvent" (water/acetone/alcohol?) is used to mix in the powder batch to soften it and extrude? Perhaps that is what "etches" the plastic? What happens when it completely evaporates as it ages?No etching, slight discoloration though

Is powder closed up in a container any more susceptible to moister than powder setting in a brass cartridge

Here we go again. Powder is hygroscopic meaning it will exchange moisture with air depending on the moisture content of the air (absolute humidity, dew point, partial pressure) not relative humidity. This is a time dependent property. Powder stored in in HDPE jugs does not permit moisture to move through the jug but very small amounts of air can move through the cap. In general the powder will not follow ambient humidity changes when stored in the original container. If stored in a particularly arid or humid environment it will eventually come to equilibrium with that environment (think Sahara or India (Monsoon)). As for packaged at 50% humidity, this is probably true and is likely done to minimize static electricity buildup that could ignite the powder during handling. The solvents used in the powder manufacture process will attack certain plastics. Properly stored the solvents do not magically disappear.

If you follow the manufacturer's recommendations and the powder handling recommendation your powder will be stable.

As for powder humidity there is no such thing. Humidity is property of air. Moisture content is a function of powder.

Tests of powder purposely modified to remove/add moisture to specific levels does indicate that moisture affects weight and heating value but we know that. Those test do not reflect the behavior of powder under normal storage conditions.

If you follow the manufacturer's recommendations and the powder handling recommendation your powder will be stable.

As for powder humidity there is no such thing. Humidity is property of air. Moisture content is a function of powder.

Tests of powder purposely modified to remove/add moisture to specific levels does indicate that moisture affects weight and heating value but we know that. Those test do not reflect the behavior of powder under normal storage conditions.

Months

Chargmaster has a pretty tight sealed cap lid on the reservoir top . I also use a rubber cap that I put over the mouth/hole of the spinning dispenser tube that dumps into the powder tray, when walking away between days loading .

I have left powder in for weeks at time on loading large volumes of .223 and never screwed with my accuracy or Vel. from hydroscopic moister . but the powder in reservoir take was run emptied and refilled pretty regularly in loading .

But topic of powder and ' Corrosive Etching ' ---> I have had seen a little etching in ' plastic and aluminum tube ' in the Chargemaster holding tank, where powder rides in the spinning pick-up tube area . I forgot about some reloader-15 once, and left a few inches powder in the bottom for few months . I threw powder out and cleaned out the area, filed and Loaded again.

also this No BullShit .. except for the power go out in the house few times for couple hours at a time over the years . I have a chargemaster that I just leave On, use regularly. The thing has been plugged full time into the AC with ( power ON ) since 2008 .

.

It is controversial to say that you should put a desiccant in your powder. Powder comes from the factory at approximately 50% humidity and drying it out will increase the energy density of a given weight and will also increase the burn rate. Those things could have adverse effects on charges that were a near max load, if the powder gets increasingly dry or overtime. And also your velocities could change from session to session if humidity were not stablePowder should always be restored to a sealed container. Perhaps with a desiccant as well. I have read several articles, as well as more than a few posts here, discussing moisture contamination at length. Some people even advocated using only 1lb bottles to avoid ruining 8lb all at once.

Will powder exposed to moisture combust? Sure. The questionable provenance reloads my father bought 30 years ago also combusted. Will powder exposed to moisture combust in a stable predictable fashion conducive to precision? Doubtful.

It is for this reason that I put 49% humidity packs in my powder to try to keep it near the factory humidity which is what I presume most reloading manuals use - the powder was tested at approximately 50% RH

Last edited:

Litz says Yes:

thescienceofaccuracy.com

thescienceofaccuracy.com

#60 - Humidity Effects on Smokeless Powder - The Science of Accuracy

thescienceofaccuracy.com

thescienceofaccuracy.com Yes, powder will pull moisture out of the air.

I keep powder sealed/stored indoors, transfer it to the garage for loading 1lb at a time and keep it sealed there too. I use a Prometheus scale and if I leave a charge overnight it will slowly drift heavier. Prometheus scale is very sensitive and you can see it will pick up about one kernels worth of weight on a charge that's around 30 grain. Super small difference but you can see it.

I keep powder sealed/stored indoors, transfer it to the garage for loading 1lb at a time and keep it sealed there too. I use a Prometheus scale and if I leave a charge overnight it will slowly drift heavier. Prometheus scale is very sensitive and you can see it will pick up about one kernels worth of weight on a charge that's around 30 grain. Super small difference but you can see it.

Many materials draw moisture from the air.

Some salts will draw moisture from very dry air. LiCl will pull moisture from air that is higher than 11%RH.

NaCl higher than 75%RH.

Silica Gel get absorb moisture until it saturates with a RH of about 40%.

Gun powder absorbs moisture. Starting off with about .5 to 1% by weight of water.

If stored @ 80% humidity (enclosed air) it will likely absorb more until the enclosed volume RH is reduced by this absorption.

If stored open if will continue to absorb.

Now, what about being stored in a container @ 30% RH, or in the open? Will it dry out?

What is the equilibrium humidity of Single or Double based powders at normal temperatures like 20 to 30C?

Under what conditions will it gain or lose moisture?

Does 50% RH sounds like a good storage and using condition?

What happens if the storage temperature reaches the dew point of the enclosed air volume?

How much water was in there in the first place (weight of water in air)?

8 pounds of powder vs 1 pound in an eight pound jug.

How long does it take to release the excess absorbed moisture when returned to normal storage temperature?

Days, weeks, never?

Some salts will draw moisture from very dry air. LiCl will pull moisture from air that is higher than 11%RH.

NaCl higher than 75%RH.

Silica Gel get absorb moisture until it saturates with a RH of about 40%.

Gun powder absorbs moisture. Starting off with about .5 to 1% by weight of water.

If stored @ 80% humidity (enclosed air) it will likely absorb more until the enclosed volume RH is reduced by this absorption.

If stored open if will continue to absorb.

Now, what about being stored in a container @ 30% RH, or in the open? Will it dry out?

What is the equilibrium humidity of Single or Double based powders at normal temperatures like 20 to 30C?

Under what conditions will it gain or lose moisture?

Does 50% RH sounds like a good storage and using condition?

What happens if the storage temperature reaches the dew point of the enclosed air volume?

How much water was in there in the first place (weight of water in air)?

8 pounds of powder vs 1 pound in an eight pound jug.

How long does it take to release the excess absorbed moisture when returned to normal storage temperature?

Days, weeks, never?

Last edited:

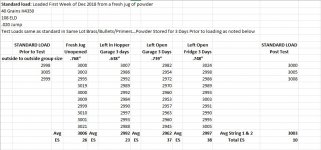

Avg String 1 and 2 was the combined 6 shots of the standard control load before and after the test to make sure they stayed similar

my garage is tied into my central AC so it stays similar to my house temps year round and doesnt have the large swings like a standard garage would

still shows a pretty obvious difference...and this was only 3 days. id bet that the powder in the closed hopper would follow the open container just at a slower rate of change...may take it 1 month to reach where the open ended up after 3 days

im also near sea level, high humidity...south tx...somewhere drier might have the opposite effect

my garage is tied into my central AC so it stays similar to my house temps year round and doesnt have the large swings like a standard garage would

still shows a pretty obvious difference...and this was only 3 days. id bet that the powder in the closed hopper would follow the open container just at a slower rate of change...may take it 1 month to reach where the open ended up after 3 days

im also near sea level, high humidity...south tx...somewhere drier might have the opposite effect

Attachments

No primers should be stored dry with desiccant.So are we saying that 50% humidity is the right amount and there is negative effects if it’s to high or to low?

Primers stored around 50% as well?

Take a half full 8# jug of powder.

About 4 lbs worth 28,000 grains of powder).

1% moisture content would be less than 300 grains of water.

The half full jug would have about 2 liters of air and weigh (dry) about 40 grains.

At 90% RH, and 70 F, water weight is about 0.015lb/lb of air.

The 2 liters of air in the jug would have less than a grain of water vapor, and now weigh about 40.6 grains.

If the powder sucked every bit of water out of the air in the jug the change in powder moisture content would be a little less than a grain.

From 300 to 301?

If the air in the half full jug was stored at 50%RH/70F would the powder absorb moisture from or release moisture to the air?

What about left open to the environment for days @50% RH/70F ?

My math might not be all that correct

About 4 lbs worth 28,000 grains of powder).

1% moisture content would be less than 300 grains of water.

The half full jug would have about 2 liters of air and weigh (dry) about 40 grains.

At 90% RH, and 70 F, water weight is about 0.015lb/lb of air.

The 2 liters of air in the jug would have less than a grain of water vapor, and now weigh about 40.6 grains.

If the powder sucked every bit of water out of the air in the jug the change in powder moisture content would be a little less than a grain.

From 300 to 301?

If the air in the half full jug was stored at 50%RH/70F would the powder absorb moisture from or release moisture to the air?

What about left open to the environment for days @50% RH/70F ?

My math might not be all that correct

Last edited:

If the jug were airtight at the interface of the cap I don’t think this would matter. However, it is not, and I live in a very hot and very arid environment. That is why I put two 49% humidity packs in each 8 pound jug. I want to start with a known quantity. Namely, I don’t want to be dispensing a charge at a certain weight and have some fraction of a grain of that be water weight. I am less able to influence any changes that occur with pressure and temperature that drives moisture into or out of a loaded cartridge. However, I highly doubt that much leaks out around the primer or the projectile. I have been meaning to ask Brian Litz about whether a lanolin based lubricant on projectiles during seating would effectively seal off the neck of the cartridges and I believe that it would. According to him, the major problem with moisture exchange in loaded cartridges has to do when you transport it across significantly different altitudes, thus forcing gas to re-pressurize in or out of the cartridge. I honestly doubt that the effects of moisture on loaded ammo are very great. I’m not going to pack my ammo boxes or ammo cans with humidity packs and stress about it (if I were shooting competitively I might). But I want to at least always start my reloading process with a powder at a known humidity - simply because it is very easy to do, and it equalizes at least one variable at one point in time.

I thought of doing that too. I’m on the fence really.I air out powder before I use it purposely. The RH in my reloading room is about 23%. Powder in my area will speed up when exposed to the dry air in Colorado. I tested this with Varget in a 6BR. Old jug vs a new jug and then aired out the new jug a couple of days and retested it. Results were 2800fps with old jug, no pressure. Same load with new jug was 2720'ish and required something like another grain to get to 2800fps and started to show pressure. After airing out for two days that same powder was 2780 and the load showed no pressure.

In my area, airing(drying?) out powder is advantageous. It also means you're not fighting a continual and inevitable change in your powder over time even though you are trying to keep it sealed. I just let it change quickly by being completely exposed to ambient conditions and then it's consistent. I have found exposed powder will level out and more or less stabilize in my area. This also means I control the powder behavior and don't have to adjust to "lot to lot variations".

One problem that is holding me back is that I don’t want to have to reduce all my loads when I start shooting with higher energy density powder that burns faster.

Similar threads

- Replies

- 32

- Views

- 1K

- Replies

- 33

- Views

- 1K