Anyone have one of these? Thinking about it for my 550 but I'm wondering if it's more trouble than it's worth. My purposes would be for precision 223 loads. I saw a guy on YouTube that rigged up a dillon case feeder to work on a 550 and thought about that too. I think he just took a 9mm piece and cut it out so a 223 case would go through it. Not sure exactly what he did. The mini looks like it works well be only holds 50 cases , probably still be a lot faster because it doesn't seem to take long to load up the magazine but I'd love someone else's comments if they have one.

- Thread starter BuildingConceptsllc

- Start date

- Tags

- dillon 550c

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

If you have a 3d printer i found a site that has a version you can print feeders for cases or bullet - only difference is the collator plate. Total cost is about $150 all in including PLA, motor, sensors etc. Use Lee Inline dropper die instead of printed one or DA. I just posted about my success with it.

Takes a bit more fiddling but works good.

Takes a bit more fiddling but works good.

I don't have a 3d printer and I saw your post in the 6mm thread but I'm not really clear on exactly what the set up it. If it's with a Mr bullet feeder or case feeder ? If it's a regular case feeder set up then it would be a ton better than that mini one to kick out some volume while dropping off press. Could you expound on your set up a little bit?If you have a 3d printer i found a site that has a version you can print feeders for cases or bullet - only difference is the collator plate. Total cost is about $150 all in including PLA, motor, sensors etc. Use Lee Inline dropper die instead of printed one or DA. I just posted about my success with it.

Takes a bit more fiddling but works good.

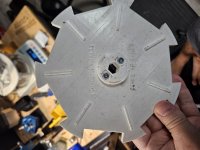

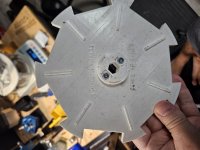

View attachment 8279467

View attachment 8279469

Kinda complicated, so hope this makes sense.

As mentioned, most of the parts between bullet and brass feeders are exactly the same. You need different collator plates and drop adapters (at bottom of springs that interface with press). Thise depend on brass or bullet sizes.

These do pretty well at feeding brass and bullets base down, but every now and then, you will get one upside down. On a 550, youd catch it. On my 750 when im cranking, you can crunch stuff .

.

If its still not very clear, I can try to get some vids.

Brass Feeder (white, mostly...)

Feeder Body (theres a little slider that you move for diff brass lengths. If case head gets to hole first, it tips the case in. If not, you adjust the slider so the case neck catches until case head falls in hole)

Brass plate (middle had a clutch so the motor spins instead of stripping out middle hole)

Bullet Feeder (mostly gray)

Bullet feeder body

Bullet collator plate for long rifle bullets

Bullet drop adapter (same as brass except smaller ID)

Proximity Switch (shuts off collator to avoid plugging up springs connecting feeder body to drop adapter)

Lee Inline Bullet dropper (better than printed if they have your caliber)

As mentioned, most of the parts between bullet and brass feeders are exactly the same. You need different collator plates and drop adapters (at bottom of springs that interface with press). Thise depend on brass or bullet sizes.

These do pretty well at feeding brass and bullets base down, but every now and then, you will get one upside down. On a 550, youd catch it. On my 750 when im cranking, you can crunch stuff

If its still not very clear, I can try to get some vids.

Brass Feeder (white, mostly...)

Feeder Body (theres a little slider that you move for diff brass lengths. If case head gets to hole first, it tips the case in. If not, you adjust the slider so the case neck catches until case head falls in hole)

Brass plate (middle had a clutch so the motor spins instead of stripping out middle hole)

Bullet Feeder (mostly gray)

Bullet feeder body

Bullet collator plate for long rifle bullets

Bullet drop adapter (same as brass except smaller ID)

Proximity Switch (shuts off collator to avoid plugging up springs connecting feeder body to drop adapter)

Lee Inline Bullet dropper (better than printed if they have your caliber)

Attachments

Ok, I gotcha now I think. Just wasn't sure about some things between bullet feeder vs cade and 550 vs 750. So with that double alpha drop tube, and a lee inline bullet dropper you got it but what piece would enable a case feeder to go into and be put in place on a 550 for a 223 case? The Lee inline bullet dropper won't do that so that's what I'm getting hung up on. Sorry, if I had more experience with progressive I'd be able to follow better. Thanks for the info

I don't understand how that would feed a case into place on a 550 and in your video of the 750 your hand blocks any view of that part. The case has to come in just in front of the shell plate and get slid into place so I'm just not quite getting how that part would work. Also could be I'm just not very bright....so...

I don't understand how that would feed a case into place on a 550 and in your video of the 750 your hand blocks any view of that part. The case has to come in just in front of the shell plate and get slid into place so I'm just not quite getting how that part would work. Also could be I'm just not very bright....so...

I have 5 positions where you have 4 but that doesnt matter.

Here's how id set up with 4.

Position 1: mandrel...found it makes seating uber consistent even if youve mandreled before

Position 2: powder and prime

Postion 3: Drop bullet using lee inline

Postion 4: seat

Highly recommend the Armanov floating tool heads. Make sizing and seating much more accurate.

Here's how id set up with 4.

Position 1: mandrel...found it makes seating uber consistent even if youve mandreled before

Position 2: powder and prime

Postion 3: Drop bullet using lee inline

Postion 4: seat

Highly recommend the Armanov floating tool heads. Make sizing and seating much more accurate.

Ok, that orange piece is what I was talking about. Id need to get one without the caliber conversion other sruff somehow. It doesnt come with 550 caliber conversions. So where did you get the black parts and how do they mount up to the press, as in where do they attach? That whole set up would probably work on a 550 too I think. Just the bullet feeding part got me confused about what exactly we were talking about but I'm with you now.Well, im short on 550 experience so Im only ASSuming case feeding mechanism is similar. Here is how mine interfaces on 750:

View attachment 8279595

The orange part comes with my dillon caliber conversions and is where their case feeder plugs in also.

@BuildingConceptsllc

I have the DAA case feeder on my 550 and like it.

Tip to make the DAA case feeder work better…sand or mill the bottom of the shell plates down to where your cases fit snug…the DAA feed arm touches the brass on the up stroke and if the case is loose in the shell plate the case will wobble out a little and not go into the sizing die and will F up the mouth/neck.

I have the DAA case feeder on my 550 and like it.

Tip to make the DAA case feeder work better…sand or mill the bottom of the shell plates down to where your cases fit snug…the DAA feed arm touches the brass on the up stroke and if the case is loose in the shell plate the case will wobble out a little and not go into the sizing die and will F up the mouth/neck.

Oooooo....I just googled a 550. Those black parts are integral to the 750/650s.

Sorry, was distracted getting the Thanksgiving feast served.

It looks like you may be better off doing the DAA mini case feeder for the brass and then you could do one of the printed ones for bullets. Note you have to buy the part that feeds the cases onto your shell holder and the mini tubes separate ($154 +47).

It also looks like Dillon has one. It costs more ($350), but you have the advantage of not using the DAA mini tubes. I think id hate loading brass by hand vs just dumping it in the hopper.

There is an adapter for the printed ones to just hang the bullet hopper off the side dillon hopper.

Sorry, was distracted getting the Thanksgiving feast served.

It looks like you may be better off doing the DAA mini case feeder for the brass and then you could do one of the printed ones for bullets. Note you have to buy the part that feeds the cases onto your shell holder and the mini tubes separate ($154 +47).

It also looks like Dillon has one. It costs more ($350), but you have the advantage of not using the DAA mini tubes. I think id hate loading brass by hand vs just dumping it in the hopper.

There is an adapter for the printed ones to just hang the bullet hopper off the side dillon hopper.

Yes the assembly there that pushes the case into the shell plate. Yes I think it's called the case feeder base assembly. Did that come with the 750 case feeder or did you get it separately? There's a case feeder that you can buy that's a dillon that comes with that or something like it, but yours just looked like it was printed so I thought it may be some aftermarket or made one or something?

Yeah there are folks who have taken that dillon case feeder and modified it. (That's what I was getting at to begin with here. The dillon set up is only for pistol, no rifle) some have modified the 9mm conversion kit and added a small rifle plate to the feeder and made some modifications to locator pins and gotten the dillon case feeder to work, I'm just wondering if that mini by DAA is going to be satisfactory enough so I wouldn't have to modify the dillon set up, which is why I was asking about your set up initially.Oooooo....I just googled a 550. Those black parts are integral to the 750/650s.

Sorry, was distracted getting the Thanksgiving feast served.

It looks like you may be better off doing the DAA mini case feeder for the brass and then you could do one of the printed ones for bullets. Note you have to buy the part that feeds the cases onto your shell holder and the mini tubes separate ($154 +47).

It also looks like Dillon has one. It costs more ($350), but you have the advantage of not using the DAA mini tubes. I think id hate loading brass by hand vs just dumping it in the hopper.

There is an adapter for the printed ones to just hang the bullet hopper off the side dillon hopper.

So if you had to over again would you get a dillon case feeder set up for the 550 and modify it or stick with the double alpha mini? Is there any way to make the DAA mini hold more cases? That's really what I'm worried about. Seems like having to fill it every 50 cases would be a pain? Am I just wrong and it's not a big deal or do you have two of the hoppers and keep one loaded to just swap out or what? Much appreciated info here sir!@BuildingConceptsllc

I have the DAA case feeder on my 550 and like it.

Tip to make the DAA case feeder work better…sand or mill the bottom of the shell plates down to where your cases fit snug…the DAA feed arm touches the brass on the up stroke and if the case is loose in the shell plate the case will wobble out a little and not go into the sizing die and will F up the mouth/neck.

So the slide plate feeder assy comes standard on the 750. I did replace it with an aftermarket that allows me to cycle the press without dropping brass, which is prolly why it looks printed. Think I bought it from Uniqutek or Armanov.

Id prolly start with a phone call to DAA. Ask em how many 223 cases you can get in there. If you can get 100, then thats an automatic pause place cuz thats all the primers you can load. Maybe you can also buy 2, load them up, and 'quick' change - kinda like loading mulriple primer tubes.

If both of those are no's, only then Id try to modify the dillon. Costs are higher, gonna be a PITA, and ultimately may not work.

Other option is to try to pick up a used 750. Sometimes its easier to simply get the right tool. The 550 wasnt really made to automate. Just my 0.02.

Id prolly start with a phone call to DAA. Ask em how many 223 cases you can get in there. If you can get 100, then thats an automatic pause place cuz thats all the primers you can load. Maybe you can also buy 2, load them up, and 'quick' change - kinda like loading mulriple primer tubes.

If both of those are no's, only then Id try to modify the dillon. Costs are higher, gonna be a PITA, and ultimately may not work.

Other option is to try to pick up a used 750. Sometimes its easier to simply get the right tool. The 550 wasnt really made to automate. Just my 0.02.

So I had a Dillon 550 with a case feeder a few years ago…short store I sold everything rifles pistols and all gear to help pay off my house…now that’s done I’m back…personally I would just buy a 750 if I really needed to load fast….I had a 750 too and they are fast once you find your groove.So if you had to over again would you get a dillon case feeder set up for the 550 and modify it or stick with the double alpha mini? Is there any way to make the DAA mini hold more cases? That's really what I'm worried about. Seems like having to fill it every 50 cases would be a pain? Am I just wrong and it's not a big deal or do you have two of the hoppers and keep one loaded to just swap out or what? Much appreciated info here sir!

I have 4 of the DAA tubes and yes they are super simple to load and no I would not spend the money it takes to buy and get a Dillon case feeder running on a 550 Id just put that money towards a 750.

Like I said the big thing is to sand or mill the shell plates so they hold the cases snug…if you don’t have a mill or smith/machine shop near you and are going to do the shell plates yourself get a cheap bench top belt sander…harbor tools.

With a very simple mod to the 45cal funnel that comes with the DAA case feeder and the shell plate sanded I can feed 6GT or similar cases.

As you know there’s a TON of things you can do to the 550…personally the shell plates, the U light, an inline fab roller handle and mounting plates is all I would recommend…I had all the bling on my first 550 and most of it did nothing to make it better…the 550 just works.

Also as @mbeavers1 said get extra primer tubes…get as many as you need for what your going to load in a session…I run 5 because I will rarely load more than 500 at a time.

Ok, that settles it. Thank you for the info. Thats what I was wanting to know. I will be getting an auto indexing press also but I'm going to run the 550 first for a bit then I might get that new mark 7 genesys but I'd really like to see some reviews about it before dropping $6500.00 on it. Either that or an 1050. I did think about the 750 but seems like I'd be better off just going the 1050 IF , I know I'm going to auto drive it. Then again, I may be better of with 2- 750's instead. Hard to say right now. I'd like to find out how hard it is to change calibers on the genesys system from people in the wild before making that determination really. If it's not bad and can be done via tool head (which I know it can but how hard and how expensive is it) and easily, it may be worth it to just have that and do pistol and rifle on it foe volume and keep my single stages and 550 for precision rifle.So I had a Dillon 550 with a case feeder a few years ago…short store I sold everything rifles pistols and all gear to help pay off my house…now that’s done I’m back…personally I would just buy a 750 if I really needed to load fast….I had a 750 too and they are fast once you find your groove.

I have 4 of the DAA tubes and yes they are super simple to load and no I would not spend the money it takes to buy and get a Dillon case feeder running on a 550 Id just put that money towards a 750.

Like I said the big thing is to sand or mill the shell plates so they hold the cases snug…if you don’t have a mill or smith/machine shop near you and are going to do the shell plates yourself get a cheap bench top belt sander…harbor tools.

With a very simple mod to the 45cal funnel that comes with the DAA case feeder and the shell plate sanded I can feed 6GT or similar cases.

As you know there’s a TON of things you can do to the 550…personally the shell plates, the U light, an inline fab roller handle and mounting plates is all I would recommend…I had all the bling on my first 550 and most of it did nothing to make it better…the 550 just works.

Everything I have seen, you will be better with the 750 for precision ammo and if you want to automate, get the autodrive. You dont have the aftermarket accessories for the 1050 that you need to float the dies.

I run two passes.

Pass 1:

Size and deprime

Mandrel

Both of those affect concentricity, so with the floated dies, they align perfectly. I am able to size with about +/-0.0005" accuracy on my 0.002" bump.

Pass 2:

Mandrel again to help with seating consistency

Charge (either with auto trickler v3 w/IP) and prime

Drop bullet

Seat

Again, i float the mandrel and the seater. Seating accuracy is as good as bump

I run two passes.

Pass 1:

Size and deprime

Mandrel

Both of those affect concentricity, so with the floated dies, they align perfectly. I am able to size with about +/-0.0005" accuracy on my 0.002" bump.

Pass 2:

Mandrel again to help with seating consistency

Charge (either with auto trickler v3 w/IP) and prime

Drop bullet

Seat

Again, i float the mandrel and the seater. Seating accuracy is as good as bump

I've heard a lot of mixed reviews on floating the dies or not. You may well be right though about the 750. But once you put a bullet feeder, case feeder, auto drive, and all the sensors on it to run an auto drive, you are getting a whole lot closer to the genesys price which has all of that on it as it comes and 3 servo motors vs 1 ram. Now if I could find a set up 750 that someone was selling that had most of what I want for a good price, then of course that would be great. I thought I was buying a apex 10 but I didn't make it fully clear that I was definitely going to buy it I guess and he sold it to someone else while I was asking questions, or I'd have that and be done. However, having 2- 750s would be nice too. One for pistol and one for rifle then do separate tool heads like I do the 550 and like you do. Brass prep, then fill and seat on tool head #2. Just do one tool head for pistol if the 750 has enough stations to accomplish that and do pistol well. I think that's really the main reason I sort of moved past the 750 but I may just be wrong about that.Everything I have seen, you will be better with the 750 for precision ammo and if you want to automate, get the autodrive. You dont have the aftermarket accessories for the 1050 that you need to float the dies.

I run two passes.

Pass 1:

Size and deprime

Mandrel

Both of those affect concentricity, so with the floated dies, they align perfectly. I am able to size with about +/-0.0005" accuracy on my 0.002" bump.

Pass 2:

Mandrel again to help with seating consistency

Charge (either with auto trickler v3 w/IP) and prime

Drop bullet

Seat

Again, i float the mandrel and the seater. Seating accuracy is as good as bump

So you don't do anything to bell the case mouth? I don't load pistol yet but that seems to be a needed thing for most?750 will do pistol easily. I just loaded 5k 9mm in 1 pass. It has 5 stations.

Size

Powder/prime

Drop bullet

Seat

Crimp

Powder funnel does that when you charge, then the crimp die fixes it.

Only time i ran a belling die was for blaster 223 with flat base bullets.

Only time i ran a belling die was for blaster 223 with flat base bullets.

Ok. I had just seen a bunch of guys doing that in a separate step or using a roller so...Powder funnel does that when you charge, then the crimp die fixes it.

Only time i ran a belling die was for blaster 223 with flat base bullets.

So arminov or whidden tool heads for 550?

I like the armanovs better. Whidden uses pins to hold the floating die rings and armanovs are threaded. For short calibers, i have to flip the heads over and put the rings on the bottom.

Ok, that settles it. Thank you for the info. Thats what I was wanting to know. I will be getting an auto indexing press also but I'm going to run the 550 first for a bit then I might get that new mark 7 genesys but I'd really like to see some reviews about it before dropping $6500.00 on it. Either that or an 1050. I did think about the 750 but seems like I'd be better off just going the 1050 IF , I know I'm going to auto drive it. Then again, I may be better of with 2- 750's instead. Hard to say right now. I'd like to find out how hard it is to change calibers on the genesys system from people in the wild before making that determination really. If it's not bad and can be done via tool head (which I know it can but how hard and how expensive is it) and easily, it may be worth it to just have that and do pistol and rifle on it foe volume and keep my single stages and 550 for precision rifle.

Do you actually shoot that many rounds a year that you NEED an auto drive press or more just WANT one?

Well at one time I shot a lot. With 2 boys, I don't shoot as much as I'd like to but I do expect to shoot more again and I expect for them to shoot too. There's also a matter of how long it takes. I don't have a lot of off time and so I don't want to spend a ton of time loading. It's worth it to me to spend the money so I don't have to spend the time loading. So for all those reasons, I want to.Do you actually shoot that many rounds a year that you NEED an auto drive press or more just WANT one?

Well at one time I shot a lot. With 2 boys, I don't shoot as much as I'd like to but I do expect to shoot more again and I expect for them to shoot too. There's also a matter of how long it takes. I don't have a lot of off time and so I don't want to spend a ton of time loading. It's worth it to me to spend the money so I don't have to spend the time loading. So for all those reasons, I want to.

Sounds like a want and need LOL!! I honestly do not think you will save a ton of time with an auto drive plus you could buy 2 fully pimped 750s and spend more time with the boys while they learn to load...or the better way to look at it is while THEY load YOUR ammo...its like having 2 auto drives.

I may be wrong about the time savings on the AD maybe some guys that own and use them can chime in here.

That's a good point. My oldest is 7 (we waited a while to have kids) and he helps me load some already. If it's just a matter of pulling the handle down then I think they would definitely help out. I let the oldest help with brass prep and the youngest (almost 3) absolutely loves to deprime and loves mechanical stuff. That's a good point I sort of overlooked.Sounds like a want and need LOL!! I honestly do not think you will save a ton of time with an auto drive plus you could buy 2 fully pimped 750s and spend more time with the boys while they learn to load...or the better way to look at it is while THEY load YOUR ammo...its like having 2 auto drives.

I may be wrong about the time savings on the AD maybe some guys that own and use them can chime in here.

That's a good point. My oldest is 7 (we waited a while to have kids) and he helps me load some already. If it's just a matter of pulling the handle down then I think they would definitely help out. I let the oldest help with brass prep and the youngest (almost 3) absolutely loves to deprime and loves mechanical stuff. That's a good point I sort of overlooked.

The things I hate most about reloading is brass prep...sizing and trimming....the 750 with a case feeder, a tool head set up with a sizer and a mandrel and a Henderson trimmer makes short work of those 2 things.

Yeah me too. I have an amp and amp mate with case feeder already but all the other crap is a slow go. I have a giraud trimmer but I am about order some of those whidden click adjust lock rings which I think will help me go a litter faster on it, though I don't have to trim all that often I like to keep the brass closer to chamber length vs trimming down. Not sure if Henderson would be faster or not.The things I hate most about reloading is brass prep...sizing and trimming....the 750 with a case feeder, a tool head set up with a sizer and a mandrel and a Henderson trimmer makes short work of those 2 things.

Yeah me too. I have an amp and amp mate with case feeder already but all the other crap is a slow go. I have a giraud trimmer but I am about order some of those whidden click adjust lock rings which I think will help me go a litter faster on it, though I don't have to trim all that often I like to keep the brass closer to chamber length vs trimming down. Not sure if Henderson would be faster or not.

Getting a little off topic but I have owned 2 Giraud's and two Henderson's and MUCH prefer the Henderson...I'm not sure about faster maybe same same...but the Henderson trims much cleaner and no sore fingers after a few hundred cases, it is also easier to adjust if need be.

I had the motorized unit last time and went with the POOR'S model this time...if its an issue I will just order the motor....I had all the bling when I sold and am going to start middle poor this time as other than a bit of time savings all that bling did not make me a better shooter....30+ barrels in different calibers did...and still not that great....I am far from a POOR and like spending so we will see where I end up LOL!!

I debated long and hard and it just seemed like the giraud was faster and easier because of having to put the case in the Henderson piece then move it into the trimmer vs just pushing the case to the stop ring directly into the giraud but having not used the Henderson I wouldn't really know. I'm not apposed to making a change if it saves me time or trouble.Getting a little off topic but I have owned 2 Giraud's and two Henderson's and MUCH prefer the Henderson...I'm not sure about faster maybe same same...but the Henderson trims much cleaner and no sore fingers after a few hundred cases, it is also easier to adjust if need be.

I had the motorized unit last time and went with the POOR'S model this time...if its an issue I will just order the motor....I had all the bling when I sold and am going to start middle poor this time as other than a bit of time savings all that bling did not make me a better shooter....30+ barrels in different calibers did...and still not that great....I am far from a POOR and like spending so we will see where I end up LOL!!

I debated long and hard and it just seemed like the giraud was faster and easier because of having to put the case in the Henderson piece then move it into the trimmer vs just pushing the case to the stop ring directly into the giraud but having not used the Henderson I wouldn't really know. I'm not apposed to making a change if it saves me time or trouble.

Like I said time savings? not sure but once you get your groove its pretty fast and just does a better/cleaner job IMHO...Honestly both are great trimmers and if you have the Giraud and its working for you stick with it but if you get a chance to try a Henderson do it.

Yeah I just did the primer bearing and shell plate bearing kit, and light. I also got some in and out bins from inline fab and a few more arminov tool heads and lock rings. I'm setting up a whole new reloading room. For the past however many years, I've only had my trusty turret press and done everything on it, which worked well but now that I have a dedicated reloading whole room vs a bench only in my basement, I have a ton more space for everything and wanted to take advantage of black friday sales to get the bulk of the set up stuff that I'm pretty sure I will get anyway, with a discount. Of course setting up a whole room all at once is pretty expensive so I have to prioritize to some degree. I also have accumulated a mec and the dillon 550 of course, so 3 presses at the moment with a space for another when I need to.And just another IMHO...I'm not sure how much up-grade stuff you have bought for your 550 but my suggestion would be to start with minimal up-grades then add as you think you need.

That said, I'm pretty positive I will want an auto indexing progressive set up and will use it a lot in the future so if I ran into a great deal I'd do it now, but I don't really have to do it now. I do need to find a better balance with precision rounds vs time it takes to produce actual precision rounds. Mainly 223 is my focus on this because I'm not going to go shoot a few thousand rounds in a month of 6cm. I can absolutely do that with 223 and pistol rounds when time permits so I'd like to be able to crank out 223 and pistol ammo when needed at a fast rate, but my expectations for my ammo is pretty high because I'm used to shooting great ammo. Finding that happy medium and total volume needed is where I'm at. As my boys shoot more and hopefully the wife does too, my ammo needs will continue to grow so I'm not as concerned about setting up for more volume than I need right now if that makes sense, I just don't want to wish I'd done it differently later.

Yeah I just did the primer bearing and shell plate bearing kit, and light. I also got some in and out bins from inline fab and a few more arminov tool heads and lock rings. I'm setting up a whole new reloading room. For the past however many years, I've only had my trusty turret press and done everything on it, which worked well but now that I have a dedicated reloading whole room vs a bench only in my basement, I have a ton more space for everything and wanted to take advantage of black friday sales to get the bulk of the set up stuff that I'm pretty sure I will get anyway, with a discount. Of course setting up a whole room all at once is pretty expensive so I have to prioritize to some degree. I also have accumulated a mec and the dillon 550 of course, so 3 presses at the moment with a space for another when I need to.

That said, I'm pretty positive I will want an auto indexing progressive set up and will use it a lot in the future so if I ran into a great deal I'd do it now, but I don't really have to do it now. I do need to find a better balance with precision rounds vs time it takes to produce actual precision rounds. Mainly 223 is my focus on this because I'm not going to go shoot a few thousand rounds in a month of 6cm. I can absolutely do that with 223 and pistol rounds when time permits so I'd like to be able to crank out 223 and pistol ammo when needed at a fast rate, but my expectations for my ammo is pretty high because I'm used to shooting great ammo. Finding that happy medium and total volume needed is where I'm at. As my boys shoot more and hopefully the wife does too, my ammo needs will continue to grow so I'm not as concerned about setting up for more volume than I need right now if that makes sense, I just don't want to wish I'd done it differently later.

Makes perfect sense and curious to hear how it all works out when you get set up.

I will post some pics in the ultimate loading room thread.(I think that's the name of it?) And will report back on my set up here and how it's working ect.... thank you for the info.Makes perfect sense and curious to hear how it all works out when you get set up.

@BuildingConceptsllc

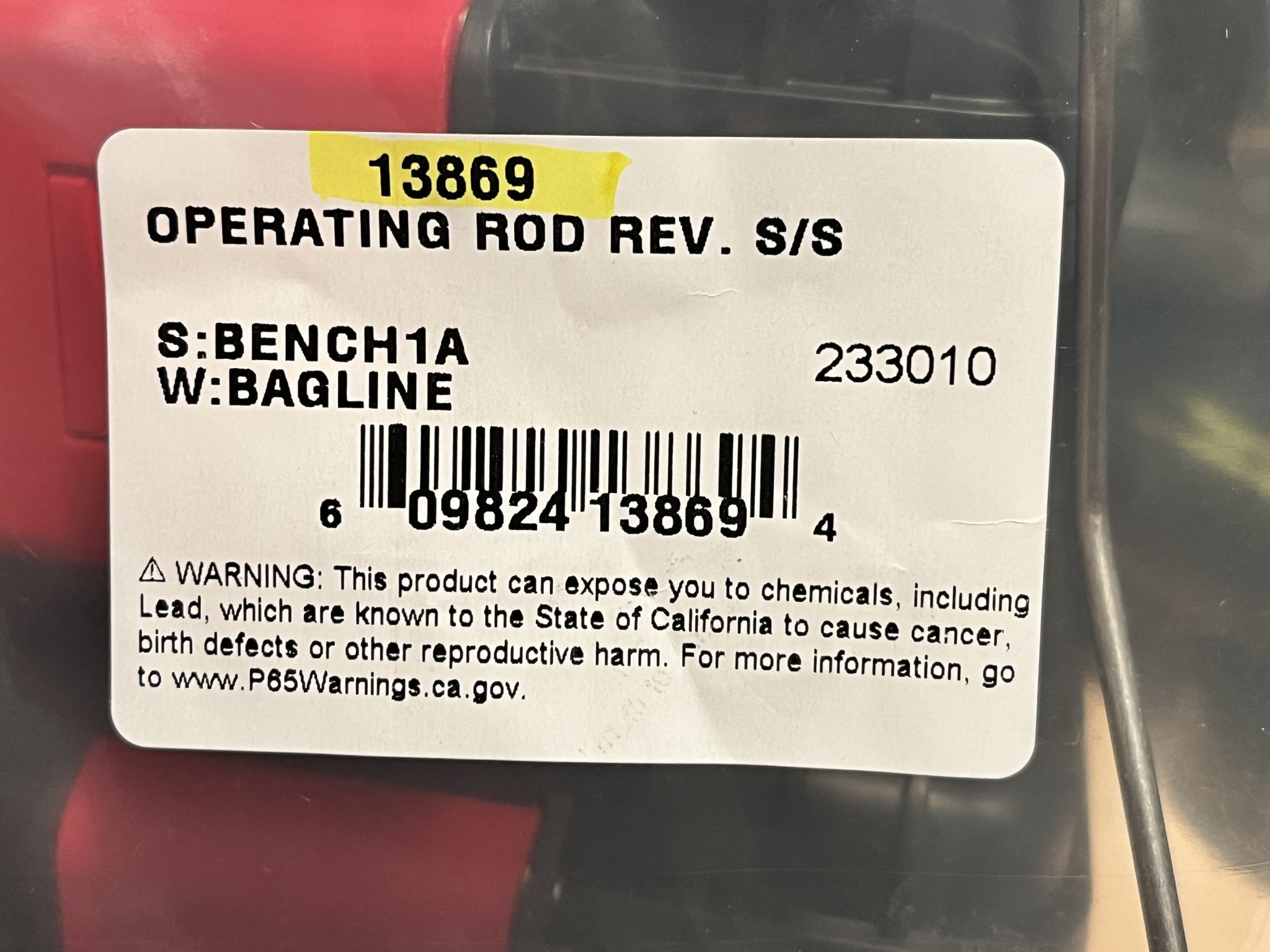

This just popped into my mind…

Here is a must have for the 550…this is the rod that actuates the primer slide I’d suggest you get 2 of them and keep one on hand at all times…trust me it will suck when one breaks…notice I said WHEN not IF…I had 2 break on my 750…one because it was out of adjustment and one around 15,000.

Looking at how the DAA roller rides on the rod it’s just a matter of time…they are only $11 bucks I think…order direct from Dillon.

This is the part number(high lighted in yellow)for the 550 it will not work on the 750 the 750 rod is different.

This just popped into my mind…

Here is a must have for the 550…this is the rod that actuates the primer slide I’d suggest you get 2 of them and keep one on hand at all times…trust me it will suck when one breaks…notice I said WHEN not IF…I had 2 break on my 750…one because it was out of adjustment and one around 15,000.

Looking at how the DAA roller rides on the rod it’s just a matter of time…they are only $11 bucks I think…order direct from Dillon.

This is the part number(high lighted in yellow)for the 550 it will not work on the 750 the 750 rod is different.

That's good to know. Will do. Is it worth it to buy a "spare parts kit" to have on hand and does that come in the kit? I don't think it does because it doesn't show it on the pic@BuildingConceptsllc

This just popped into my mind…

Here is a must have for the 550…this is the rod that actuates the primer slide I’d suggest you get 2 of them and keep one on hand at all times…trust me it will suck when one breaks…notice I said WHEN not IF…I had 2 break on my 750…one because it was out of adjustment and one around 15,000.

Looking at how the DAA roller rides on the rod it’s just a matter of time…they are only $11 bucks I think…order direct from Dillon.

This is the part number(high lighted in yellow)for the 550 it will not work on the 750 the 750 rod is different.

View attachment 8280352

Yes to the spare parts kit and no the actuating rod does not come in the kit.That's good to know. Will do. Is it worth it to buy a "spare parts kit" to have on hand and does that come in the kit? I don't think it does because it doesn't show it on the pic

Similar threads

Reloading Equipment Dillon 750XL Dust Cover, Mini Mr. Bullet Feeders

- Replies

- 2

- Views

- 384

- Replies

- 82

- Views

- 2K

- Replies

- 166

- Views

- 4K

Reloading Equipment Dillon 550 cal conversion kits, feeder slides, feeder adapters

- Replies

- 4

- Views

- 503