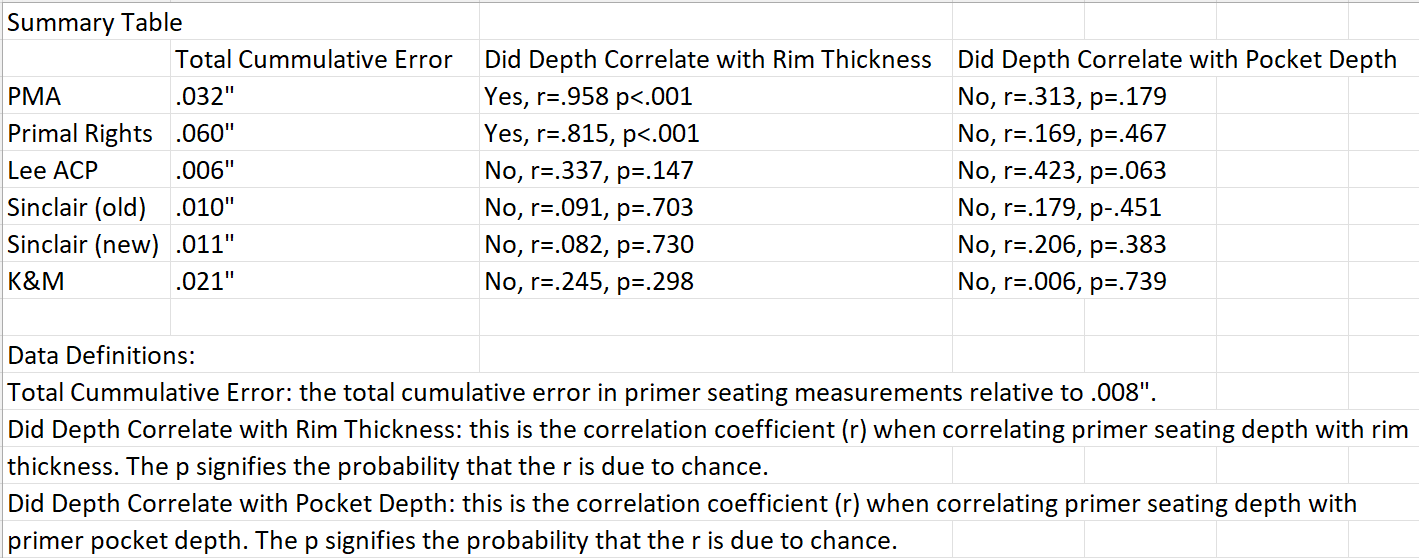

Data on priming tools. Tools that are rim thickness dependent (primer seating depth depends on the brass’ rim thickness) will have a yes under the “did depth correlate with rim thickness” column.

Last edited:

It would be nice if something had the Lee design but was made very solid so that all of these functions, including being able to vary primer seating depth, are reliable and simple.I found a Lee ACP so I will be trying it out when it gets here. Hopefully I can get it running smoothly. I sure wish there was a way to get it to work with primer tubes instead of the lee thingy but hopefully it will be a good addition to my room.

You'd think someone could make a set up that worked like the Lee acp but used dillon primer tubes and that was made really well. It would definitely be a seller.

I’m not sure if I included that data in my videos but there is no velocity difference by depth. Only observed effect was a difference in precision.Will there be a follow up with how the depth variance correlates with velocity variance?

Roger - haven’t seen the video. I’ll take a peek later. Interesting point that it doesn’t correlate with velocity.I’m not sure if I included that data in my videos but there is no velocity difference by depth. Only observed effect was a difference in precision.

What’s a target scan? The target on the seating depth and precision test is in the video. There is a follow up video to this one too with target data:Roger - haven’t seen the video. I’ll take a peek later. Interesting point that it doesn’t correlate with velocity.

Would you be willing to post a target scan?

What’s a target scan? The target on the seating depth and precision test is in the video.

I like that idea! So far, I’ve been measuring groups, entering the data, and then analyzing the data. I then put the used targets in a bin in no particular order. I should start scanning the targets and keeping an electronic record of them.I just meant a picture of the target. Sorry, I’ve been scanning mine into my computer lately so I defaulted to that

Total expected variance in rim thickness was .0585” so the error in the Primal Rights was just about the same as the expected which explains why the correlation coefficient was almost perfect. In a nutshell, the tool could not mitigate any of the expected error from rim thickness variation.Just taking a glance over the data. The Primal Rights for example.....is the data suggesting that the .060 total error was do to .060 (or close) total variance in that sample of rim thickness?

Or is there still an amount of error in the PR that is unaccounted for?

That is awesome news! It seems to be performing great for me and I’ve primed several hundred at this point…maybe a thousand.I recently primed some 6ppc on a Lee ACP. Now maybe it’s a coincidence. However I shot the smallest group(s) I’ve ever shot. Several in the zeros. This load in this rifle has shot zeros in the past . However this time out it just wanted to keep shooting dots . I’ll have to get out and do some more testing. That being said I will be priming on the Lee from this point forward. The consistency in primer depth is dead nuts.

Total expected variance in rim thickness was .0585” so the error in the Primal Rights was just about the same as the expected which explains why the correlation coefficient was almost perfect. In a nutshell, the tool could not mitigate any of the expected error from rim thickness variation.

Not sure if that’s where the variation is coming from on the cps. Hopefully Bryan will chime in. However any primer seater utilizing a shell holder will have a variance. Due to rim thickness.

Target, yes. Chrono, no. My initial approach was to see if there is a sweet spot with the seating depth and I definitely found one. I then tested depth vs anvil compression and anvil compression was the factor affecting precision. I now set my primers to the sweet spot of anvil compression which in a few of my applications is within .007-.010 of anvil compression. This manifests in various depths depending on primer height and cup depth. I then took several different seated depths to the range to test if variable depths/anvil compressions shot on the same target with 5-shot groups with the same rifle, bullets, charge, etc would make any difference. It did. When the depths were variable (eg, a few in the sweet spot and a couple others out of the sweet spot), the groups grew substantially. When I shot within the sweet spot, the groups got back in tune. Based on all these tests, I can say that practically, consistent seating depths within the sweet spot is best.I’m looking for a practical take away- Is there a difference on target or chronograph between these primer seating methods? Or is that beyond the scope?

I see the previous depth test videos, but I mean strictly as it relates to these variances in seating depth in the OP chart.

He hasn't tested these specific depth variations to see if they behave any different on target but since he did test several different primer seating depths previously and got conclusive results I wouldn't think he test the same thing again just to use these depths vs the ones already tested. Maybe I'm not understanding what you're asking here?I’m looking for a practical take away- Is there a difference on target or chronograph between these primer seating methods? Or is that beyond the scope?

I see the previous depth test videos, but I mean strictly as it relates to these variances in seating depth in the OP chart.

He hasn't tested these specific depth variations to see if they behave any different on target but since he did test several different primer seating depths previously and got conclusive results I wouldn't think he test the same thing again just to use these depths vs the ones already tested. Maybe I'm not understanding what you're asking here?

Did they have more where you found yours? I haven't had any luck finding one.I found a Lee ACP so I will be trying it out when it gets here.

I had to get it off ebay from a guy who had em in Europe and pay way too much for it. It's new but it's the only way that I've found to get one.Did they have more where you found yours? I haven't had any luck finding one.

Thanks.

Did they have more where you found yours? I haven't had any luck finding one.

Yes, many were outside the sweet spot. One strategy you could take if you have a rim thickness dependent primer seater that you plan to continue to use is to measure rim thickness and shoot the ones within the sweet spot. That is what Speedy Gonzalez does. He made a nifty device that rapidly measure rim thickness and he sorts out any cases that put him out of the sweet spot. That’s basically my strategy for matches where I load that the match with my PMA or 21st Century priming tools. Or I will seat a primer and if it seats outside the sweet spot, I’ll cull out that piece and use it for a cold bore fouler.That’s pretty much what I’m asking.

@Bryan Zolnikov

Understood you found a difference in precision between depths- Does the variance in seating depth produced by the primal rights cps push the seating depth out of this sweet spot?

I heard that there are plenty in circulation in Australia but I haven’t verified that. There are strategies to take to get consistent seating though even with the rim thickness dependent tools. I just posted about the possible methods on this thread.Between Bryan and F-class John making videos on the ACP, what few there were floating around in inventory seem to have gotten snapped up.

There's a guy in Australia that has a bunch of em, I don't think it's really a matter of there being plenty as much as that one guy has a bunch and is selling them for around $180 + $50 shippingI heard that there are plenty in circulation in Australia but I haven’t verified that. There are strategies to take to get consistent seating though even with the rim thickness dependent tools. I just posted about the possible methods on this thread.

I'm calling BS on this one. There is no mention of what the primer pocket depth was. There was also no mention of was the tool run to through/total movement or was it stopped when you felt the primer was fully seated.Data on priming tools. Tools that are rim thickness dependent (primer seating depth depends on the brass’ rim thickness) will have a yes under the “did depth correlate with rim thickness” column.

View attachment 8296815

So you didn't watch the video then?I'm calling BS on this one. There is no mention of what the primer pocket depth was. There was also no mention of was the tool run to through/total movement or was it stopped when you felt the primer was fully seated.

If you want anyone to follow or believe in what you are try to say then you need to provide more information.

About time! I was wondering when the first one was going to arrive and the quality. I honestly didn’t expect this. I was expecting the first to be one of the following:So you didn't watch the video then?

I'm not sure why everyone gets so attached to this stuff. I expected to see something like that also but have been pleasantly surprised thus far.About time! I was wondering when the first one was going to arrive and the quality. I honestly didn’t expect this. I was expecting the first to be one of the following:

- brand loyalist: somebody who is upset that their brand didn’t do the best. Response manifests in many ways but usually takes the form of “you just don’t know how to use the tool”

- science denier: “data is stupid”

- misoneist - the good ole “we’ve done it by feel for 50 years and that works”

- loose associator - introduces information in a bombshell manner proclaiming all is wrong and they are right. The information is in no way related but exhibits a great deal of mental gymnastics to appear loosely related yet so important that it nullifies the data

Anyway, I was really expecting one of these four to be the first occurrence but we got a simple impulsive disoriented one instead

I have lots of brass that are very consistent. Maybe only a few are culled out because of too much variation so I know , like all other reloading components, there are good and bad lots. I just hope manufacturing gets great enough to very consistently have good lots.I'm not sure why everyone gets so attached to this stuff. I expected to see something like that also but have been pleasantly surprised thus far.

I'm always in search of a better way, and when it comes to loading, an EASIER/FASTER way is better still. I hope I can get the LEE working well and running smoothly so I can use it with at least the same speed as my FA hand primers. (That's my normal method of priming and allows seating depth adjustment but still uses a shell holder).

I'd be interested to see how much variation there is in a few lots of lapua and starline brass though. I sort of suspect that they will be more consistent than the Norma and thus, make this not as important a factor. If the brass is more consistent in the shell holder, then it may be consistent enough to stay in that sweet spot though a .003" sweet spot is small in terms of the brass's consistency in how it sits in the shell holder.

.06" variance in rim thickness? Is that a typo meant to be .006"?Just taking a glance over the data. The Primal Rights for example.....is the data suggesting that the .060 total error was do to .060 (or close) total variance in that sample of rim thickness?

Or is there still an amount of error in the PR that is unaccounted for?

It’s cumulative error for the 20 pieces of brass..06" variance in rim thickness? Is that a typo meant to be .006"?

.0625" is 1/16". That seems huge for rim thickness variation.

I'm not trying to be a dick, just want clarification that the measurement is accurate.

So you didn't watch the video then?

During your priming process with the CPS/F-Class Plate do you end up having to measure and adjust CPS depth settings for each individual case to get the priming right? I own a CPS (due to aging hands) and it sounds like the plate is the only way to salvage this situation. Any tips and tricks would be appreciated.Agreed. Was just making sure the amount of error = the amount of rim thickness variance.

We personally use the F Class Products add on plate for the CPS. So it mitigates most of the rim variance from our ammo.

Target, yes. Chrono, no. My initial approach was to see if there is a sweet spot with the seating depth and I definitely found one. I then tested depth vs anvil compression and anvil compression was the factor affecting precision. I now set my primers to the sweet spot of anvil compression which in a few of my applications is within .007-.010 of anvil compression. This manifests in various depths depending on primer height and cup depth. I then took several different seated depths to the range to test if variable depths/anvil compressions shot on the same target with 5-shot groups with the same rifle, bullets, charge, etc would make any difference. It did. When the depths were variable (eg, a few in the sweet spot and a couple others out of the sweet spot), the groups grew substantially. When I shot within the sweet spot, the groups got back in tune. Based on all these tests, I can say that practically, consistent seating depths within the sweet spot is best.

Usually +\-.002” I set my tolerance to .001”. I know Speedy sets his at .0005”.How much variation takes you out of the "sweet spot"?

I see you’re familiar with the tuner crowd.About time! I was wondering when the first one was going to arrive and the quality. I honestly didn’t expect this. I was expecting the first to be one of the following:

- science denier: “data is stupid”

- loose associator - introduces information in a bombshell manner proclaiming all is wrong and they are right. The information is in no way related but exhibits a great deal of mental gymnastics to appear loosely related yet so important that it nullifies the data

Anyway, I was really expecting one of these four to be the first occurrence but we got a simple impulsive disoriented one instead

I see you’re familiar with the tuner crowd.

He talks about how he seated them with each tool. He double taps each one spinning it 180 degrees in between tap 1 and tap 2. When looking at the results he talks about the variation and how it's a result of rim thickness.I didn't watch the video before posting. I then watched the video and didn't see or hear anything about rim thickness or primer seating process, only primer seating depth.

Total expected variance in rim thickness was .0585” so the error in the Primal Rights was just about the same as the expected which explains why the correlation coefficient was almost perfect. In a nutshell, the tool could not mitigate any of the expected error from rim thickness variation.

I picked one up off ebay as well. The cost was around the same as an optioned out F-Class plate for the CPS. Overall just another drop in the bucket.I had to get it off ebay from a guy who had em in Europe and pay way too much for it. It's new but it's the only way that I've found to get one.

This is just a small sample but this Lapua palma brass seemed to have a much lower SD in rim thickness than the brass Bryan used.

Yes, you have a decent lot. I actually intentionally used a bad lot so I can have the variability to show the effect. If you have great consistency in rim thickness, then a rim thickness dependent tool is okay to use.I think this answer to the question posed by @Rio Precision Gunworks is crucial. Bryan’s research is very good and makes logical sense explaining seating depth variance. Primer seating variance is almost entirely explained by Rim Thickness for the CPS tool and probably for other similar tools. This begs the question (or research) asking which brass manufacturer produces brass with the minimum rim thickness variance. If, for example, brass X has very low variations in rim thickness, then tools like the CPS would have minimal seating depth variance.

I did a quick comparison of ten pieces of new Lapua 308 Palma brass and ten pieces of once-fired Lapua 308 Palma brass looking at rim thickness.

RIM thickness - inch

New. Once fired

1. .052 .052

2. .052 .052

3. .051 .052

4. .052 .052

5. .052 .050

6. .054 .052

7. .052 .052

8. .052 .051

9. .053 .052

10. .052 .052

Mean .0522 .0517

SD. .0008 .0007

This is just a small sample but this Lapua palma brass seemed to have a much lower SD in rim thickness than the brass Bryan used.

No. I’d say that I’m not really a big product tester. I primarily test to see if any differences in certain loading and shooting practices impact precision and, sometimes, ballistics. I do some product testing here and there but not necessarily for the sake of highlighting any particular brand. For example, I tested three tuners to see if they could perform certain functions. Just so happens that all three performed in very similar ways. I wasn’t necessarily testing the brand of the tuner but whether it does certain things. Same with priming tools…I tested a handful of them just to see if they’re rim thickness dependent, not to assess a particular brand. I tell you what though, if I could match my day and night job salaries, I’d do all of this in a heartbeat@Bryan Zolnikov , have you done any testing on various manufacturers of brass and how their rim thickness consistency is , or how lapua is from lot to lot? Just curious really.