This is a legit question from a relatively new shooter...

Can someone educate me as to why there is such a wide discrepancy btw a Proof prefit and what I would be quoted from a reputable smith to one-off a non-Proof prefit?

My hunch would be that "well, Proofs are mass produced and therefore have economies of scale?". But I don't know for sure. And, if so, does that come with a QC/QA tradeoff?

Are Proofs a different grade steel? Do they spend less on marketing and don't have to pass that on to the consumer? Something else?

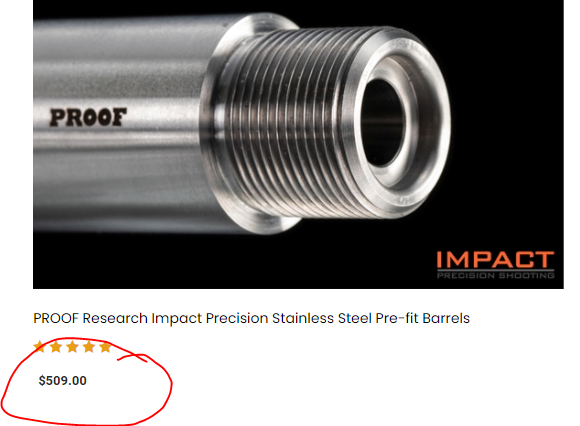

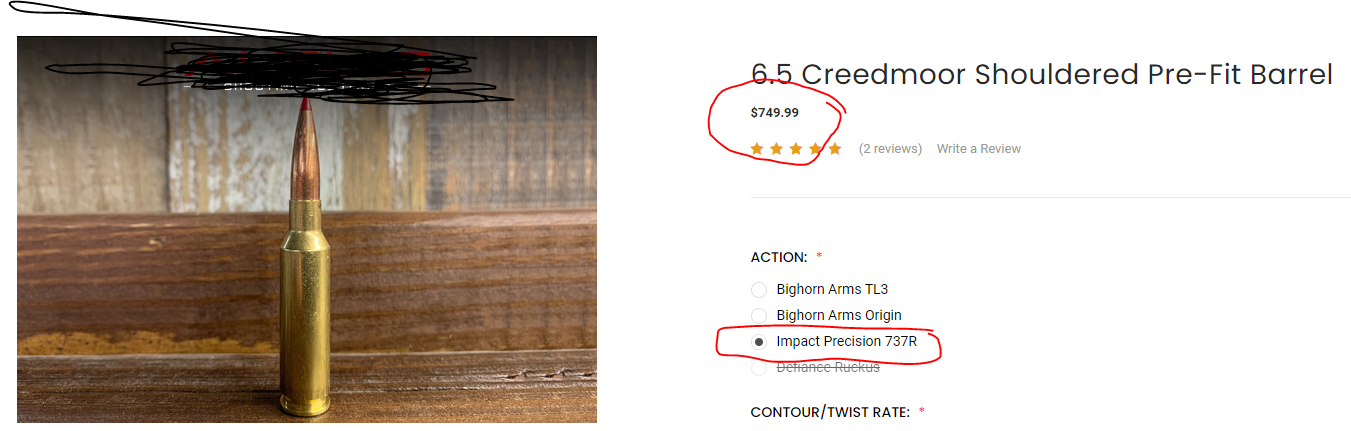

For example, a Proof prefit at this particular smith for an Impact is $509, while a "shouldered prefit" for an Impact starts at $749.99.

This trend is consistent across all smiths that offer both and consistent across calibers and actions where the "Proof prefit" is a few hundred less.

I have no problem going this route given the $ savings I can invest in bullets and powder.

Can someone educate me as to why there is such a wide discrepancy btw a Proof prefit and what I would be quoted from a reputable smith to one-off a non-Proof prefit?

My hunch would be that "well, Proofs are mass produced and therefore have economies of scale?". But I don't know for sure. And, if so, does that come with a QC/QA tradeoff?

Are Proofs a different grade steel? Do they spend less on marketing and don't have to pass that on to the consumer? Something else?

For example, a Proof prefit at this particular smith for an Impact is $509, while a "shouldered prefit" for an Impact starts at $749.99.

This trend is consistent across all smiths that offer both and consistent across calibers and actions where the "Proof prefit" is a few hundred less.

I have no problem going this route given the $ savings I can invest in bullets and powder.

Last edited: