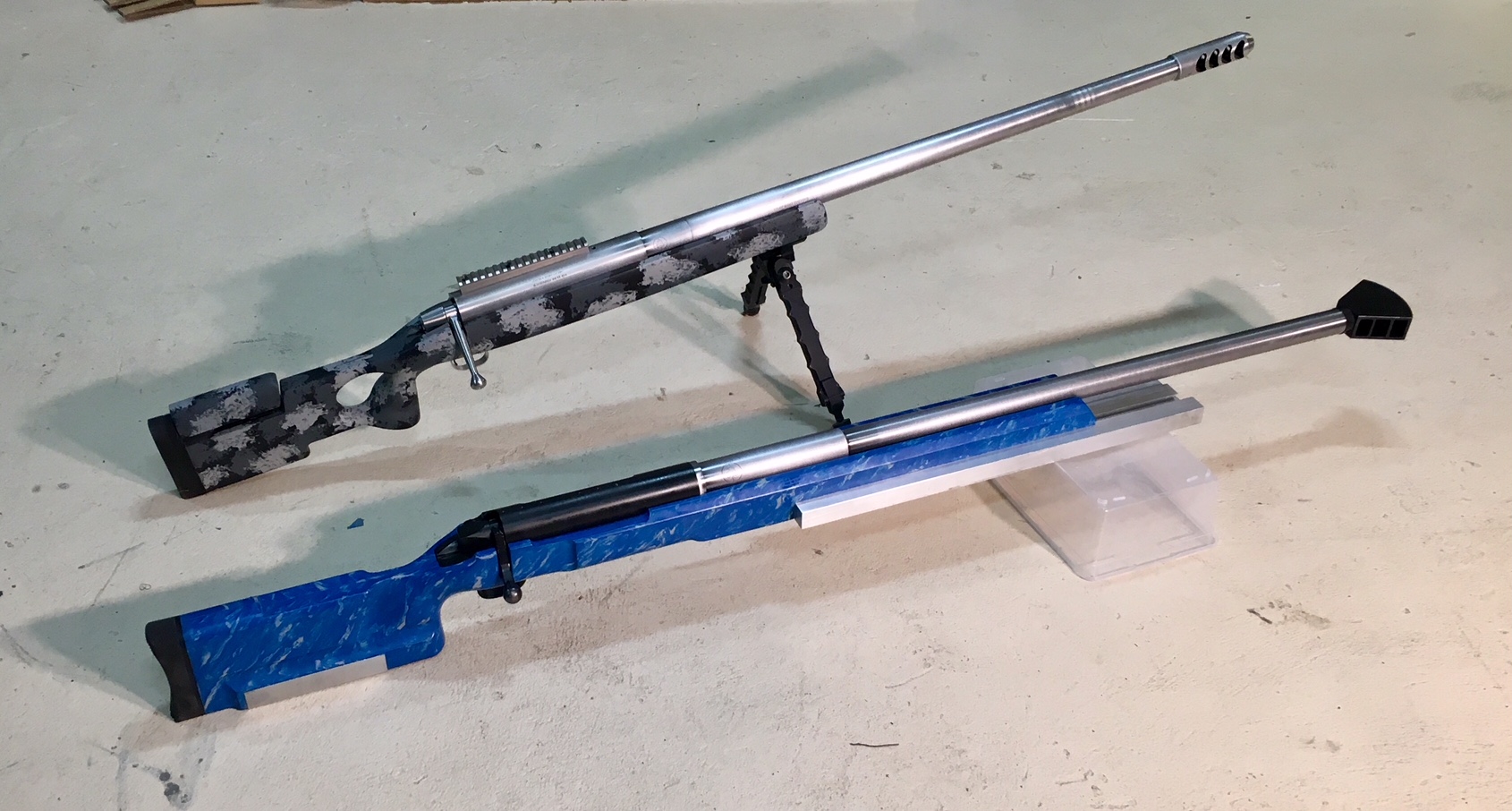

It's a BMG necked down to .375 and going to pack a punch. I chambered the rifle up for the Northern Ca URSA match director. My lathe can accommodate barrels up to 2" in diameter which is why he made the drive to see me. If he can find a good load that stabilizes the solids the other competitors are going to be in trouble. Either way it's going to be fun watching the development in the ELR game with this round even though it's been around for awhile. Could be in the vicinity of 3900fps! It's the rifle dressed in blue. Also that's just a dummy round so disregard the case damage. Rifle still needs to be bedded before testing.

- Thread starter BillyGoatMachine

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hi,

I am doing an improved version right now

Depending on what projectile weight he is wanting to shoot, his MV could be pushing 4200fps.

Barrel eaters but who cares lol...

Edited To Add:

@skkeeter I am assuming he is not building to stay under the KO2M lowered weight limits for next year ?

?

I look at the weights listed on the KO2M standing update and see how many are overweight for next years weight (unless something changes).

That new weight limit is going to be the only "limitation" to the up and coming wildcats based on the BMG brass IMO.

Nice to see Lynn build a new one.

Sincerely,

Theis

I am doing an improved version right now

Depending on what projectile weight he is wanting to shoot, his MV could be pushing 4200fps.

Barrel eaters but who cares lol...

Edited To Add:

@skkeeter I am assuming he is not building to stay under the KO2M lowered weight limits for next year

I look at the weights listed on the KO2M standing update and see how many are overweight for next years weight (unless something changes).

That new weight limit is going to be the only "limitation" to the up and coming wildcats based on the BMG brass IMO.

Nice to see Lynn build a new one.

Sincerely,

Theis

Last edited:

You might have to change the barrels about the same time most would clean, but if you are pushing those into the 4200fps range, it might bring a whole new level of repeatably and first shot capability to those trying to push close to 4000 yards and rule at the 2000 yard range.

Hi,

Back in the day Klaus averaged about 900 rounds IIRC with his monolithic projectiles but projectile design, barrel manufacturers willing to change rifling profiles and metal coatings have advanced since then, so barrel life could be a little more than that but I doubt much more.

Sincerely,

Theis

Back in the day Klaus averaged about 900 rounds IIRC with his monolithic projectiles but projectile design, barrel manufacturers willing to change rifling profiles and metal coatings have advanced since then, so barrel life could be a little more than that but I doubt much more.

Sincerely,

Theis

I believe they pushed the 40lb limit to 2020... there is another year of 45lb. I don't see a problem eating up a barrel before 2020. Garrett Fravert is using a bmg necked down to 416 and I'm pretty sure he is over 3600fps. So I would assume you'd be close to 4K.

Last edited:

You'll be burnin' mucho powda !!!

220-240gr?

I doubt Lynn is building this for the Ko2m. I think he mentioned 361 and 400g solids for the loads, not sure which powder. But yeah, Lynn's probably got plenty of it lol. I think the biggest hurdle with these wildcats are getting dies made, which he already has. I know he's been waiting a year on Snipetac dies as I built him one awhile ago that's still virgin. My rifles are shooting fantastic at the URSA events, and hopefully one day they will make it to the Ko2m matches. By the way, anyone looking for some fast turnaround times for a build, my backlog is pretty much caught up. I've got a 1 week turnaround on customer supplied parts builds, for the moment.

Keep us posted on your results. Definitely out of my pocketbook range, but VERY interesting!

Hi,

Dies are for sure a pain in these big wildcats but stocks are also huge hurdle for people not wanting the block style BR stocks.

Off the shelf powders that he is testing are RE50,US869 and VV20N29.

VV hopefully gives him the best MV but it can be erratic with temperature changes. Hopefully Lynn has a temp box that he can use to regulate and keep cartridges at same temp.

Also taking the guts from one of those laser thermometers and building it into a cartridge that would operate with bolt closure would be good to keep track of real time chamber temps instead of relying on external barrel temp for a chamber temp gauge.

Sincerely,

Theis

Dies are for sure a pain in these big wildcats but stocks are also huge hurdle for people not wanting the block style BR stocks.

Off the shelf powders that he is testing are RE50,US869 and VV20N29.

VV hopefully gives him the best MV but it can be erratic with temperature changes. Hopefully Lynn has a temp box that he can use to regulate and keep cartridges at same temp.

Also taking the guts from one of those laser thermometers and building it into a cartridge that would operate with bolt closure would be good to keep track of real time chamber temps instead of relying on external barrel temp for a chamber temp gauge.

Sincerely,

Theis

Well, if all of us collectively engage the powder makers to develop a powder that will actually work in these wildcats, we're out of luck.

Any of them, ( our 375 Warner, 416 Warner, Barrett in 374 or 416, or others similar) have to go way over pressure of what a 50 BMG case will withstand

to get to velocities we are looking for. @ 3550 w/ our 361, pressure makes the case useless after the 4th firing. Similar results with the others mentioned. I've made some press tooling to reform and recover the rim and pocket to as new, but it is not viable for a commercial cartridge.

I'm experimenting with a reinforced design (three versions actually) and so far, have gotten to 3670 with no damage. Just under 3500 w/ the 400 Flat Line. My goal is 10 to 15 reloads before having to toss the brass. Did I mention I'd pay 10 grand for a ceramic barrel?

Frank, Tracey, you listening?????????

Alan

Any of them, ( our 375 Warner, 416 Warner, Barrett in 374 or 416, or others similar) have to go way over pressure of what a 50 BMG case will withstand

to get to velocities we are looking for. @ 3550 w/ our 361, pressure makes the case useless after the 4th firing. Similar results with the others mentioned. I've made some press tooling to reform and recover the rim and pocket to as new, but it is not viable for a commercial cartridge.

I'm experimenting with a reinforced design (three versions actually) and so far, have gotten to 3670 with no damage. Just under 3500 w/ the 400 Flat Line. My goal is 10 to 15 reloads before having to toss the brass. Did I mention I'd pay 10 grand for a ceramic barrel?

Frank, Tracey, you listening?????????

Alan

I would think one of the powder companies would listen. The big rounds eat a lot of powder! Sell in 20lb or 50lb containers also.

I think hes going to fireform some loads this weekend

Let me know if you go with him. How was your hunt? and hopefully you didn't get stuck is that mess of a highway closure that caught Lynn on Monday night.

Let me know if you go with him. How was your hunt? and hopefully you didn't get stuck is that mess of a highway closure that caught Lynn on Monday night.

Super thick , we need some game cameras to help narrow down the time frame.

I drove past closure when it was happening, and I thought it was a car accident, the shooter was probably walking down the freeway right by me

Super thick , we need some game cameras to help narrow down the time frame.

I drove past closure when it was happening, and I thought it was a car accident, the shooter was probably walking down the freeway right by me

Alan

Have you tried any Vectan powder available from ShadyGrady?

And did you try any of the blends using H4895 and 20mm surplus powder?

For the fireform loads I will be using 350 Sierra's and US869 or RE50 because I have them and they are cheaper than VV20N29.

In my original barrel my load was 218 grains of 20N29 with a 330 grain solid but that was many many years ago.

On the way home from BillyGoat Machine they closed the second biggest freeway in the state for almost 8 hours. I slept in the front seat of my truck until it re-opened at 11:57 PM then waited for the 1000's of trucks and cars to get home at 1:45AM.

I did see a hitchhiker north of town but doubt he was the murderer they where looking for.

Barrel is 38 inches long.

Bedding the gun today.

It's the 4th of July so once the fireworks start going off I can most likely get a few loads fireform without a visit from the police.

Hi,

Lynn do you have or have access to WC872?

Sincerely,

Theis

Lynn do you have or have access to WC872?

Sincerely,

Theis

Hi,

Also taking the guts from one of those laser thermometers and building it into a cartridge that would operate with bolt closure would be good to keep track of real time chamber temps instead of relying on external barrel temp for a chamber temp gauge.

Sincerely,

Theis

Not sure if you excluded it for some reason, but you could use a thermacouple to get those temps pretty quickly and easily, and they are not that expensive.

Thermocouple Example

You could rig the ends of the wires into sometype of a dummy cartridge that you could chamber. You could get temps from various locations based on where you put them. Just chamber the dummy round, let is set for a couple of seconds, and you could see the temps on the reader.

Gotta love this crazy ELR stuff!

Theis

I don't have any 872 but it is available.

Vectan has a powder slower than SP13 that should work as well.

Klaus was getting up to 4800 FPS but he didn't shoot heavy bullets. My memory isn't very good but I think the heaviest he used was 320 or 330 but don't quote me on that.

If Hoffer makes us some flashtubes they will displace about 55-60 grains of powder and give us another 75 FPS. We would need to leave the end of the flashtube open so we can deprime the case and use Dacron wadding to keep kernels of powder from getting inside.

In the old old old days when I had hair we used 20mm cannon powder that was too slow. You would fill the case and not get much pressure.

You would then blend in some faster burning powder up the pressure but this isn't for the faint of heart.

I don't have any 872 but it is available.

Vectan has a powder slower than SP13 that should work as well.

Klaus was getting up to 4800 FPS but he didn't shoot heavy bullets. My memory isn't very good but I think the heaviest he used was 320 or 330 but don't quote me on that.

If Hoffer makes us some flashtubes they will displace about 55-60 grains of powder and give us another 75 FPS. We would need to leave the end of the flashtube open so we can deprime the case and use Dacron wadding to keep kernels of powder from getting inside.

In the old old old days when I had hair we used 20mm cannon powder that was too slow. You would fill the case and not get much pressure.

You would then blend in some faster burning powder up the pressure but this isn't for the faint of heart.

Hi,

IIRC Klaus's solid bronze bullets were 300gr. So yes he liked the lightweight bullets better

I am not dealing with blending powders myself lol.

Come on Hoffer....we need those flashtubes.

Sincerely,

Theis

IIRC Klaus's solid bronze bullets were 300gr. So yes he liked the lightweight bullets better

I am not dealing with blending powders myself lol.

Come on Hoffer....we need those flashtubes.

Sincerely,

Theis

Send me a drawing

Hey how did I become a Sergeant and Theis is still a Private?

Theis' KO didn't like him.

We ran RE50 today and the 350 Sierra Matchkings because I had 500 of them laying around.

I ran 185 190 195 and 200 grains with 200 grains giving me 3484 FPS.

The case once fireformed holds 285.5 grains of water.

I will try US869 and VV20N29 when I get some better brass.

I was using factory Barrett brass made by IMI but have a connection that has buckets of TZZ IMI brass which is much stronger.

Only shot 16 rounds today but the gun is a pussycat to shoot.

I ran 185 190 195 and 200 grains with 200 grains giving me 3484 FPS.

The case once fireformed holds 285.5 grains of water.

I will try US869 and VV20N29 when I get some better brass.

I was using factory Barrett brass made by IMI but have a connection that has buckets of TZZ IMI brass which is much stronger.

Only shot 16 rounds today but the gun is a pussycat to shoot.

We ran RE50 today and the 350 Sierra Matchkings because I had 500 of them laying around.

I ran 185 190 195 and 200 grains with 200 grains giving me 3484 FPS.

The case once fireformed holds 285.5 grains of water.

I will try US869 and VV20N29 when I get some better brass.

I was using factory Barrett brass made by IMI but have a connection that has buckets of TZZ IMI brass which is much stronger.

Only shot 16 rounds today but the gun is a pussycat to shoot.

Lynn - please post a pic of the fire-formed case. Thanks.

Well, if all of us collectively engage the powder makers to develop a powder that will actually work in these wildcats, we're out of luck.

Any of them, ( our 375 Warner, 416 Warner, Barrett in 374 or 416, or others similar) have to go way over pressure of what a 50 BMG case will withstand

to get to velocities we are looking for. @ 3550 w/ our 361, pressure makes the case useless after the 4th firing. Similar results with the others mentioned. I've made some press tooling to reform and recover the rim and pocket to as new, but it is not viable for a commercial cartridge.

I'm experimenting with a reinforced design (three versions actually) and so far, have gotten to 3670 with no damage. Just under 3500 w/ the 400 Flat Line. My goal is 10 to 15 reloads before having to toss the brass. Did I mention I'd pay 10 grand for a ceramic barrel?

Frank, Tracey, you listening?????????

Alan

Alan - Why a ceramic barrel? Just curious as we at Gila Defense Systems developed the first ever patent pending, commercially available ceramic ammunition. The pistol ammunition is available now but only to MIL/LE. For other platforms, the really good stuff continues to be suppressed by our friends at Picatinny Arsenal. Our battle with them is now going on year three. I've never seen anything so corrupt and sicking in my life. But any way curious about the barrel requirement.

Alan - Why a ceramic barrel? Just curious as we at Gila Defense Systems developed the first ever patent pending, commercially available ceramic ammunition. The pistol ammunition is available now but only to MIL/LE. For other platforms, the really good stuff continues to be suppressed by our friends at Picatinny Arsenal. Our battle with them is now going on year three. I've never seen anything so corrupt and sicking in my life. But any way curious about the barrel requirement.

I worked on a team that developed a self-reinforcing silicon nitride ceramic barrel. The best prototypes we produced performed exceptionally but it was difficult to achieve consistency and costs were astronomical.

Barrels, like tires on a race car, by nature are a wear item. The harder you run them, the shorter their life. We've all been there; you just get your barrel and load working great and all of a sudden it is shot out. Each cartridge/load generally dictates how long it will last, but it is inevitable that it will !*#t the bed at some point. We all expect to embark on the process of changing barrels because of this, but we must admit that no matter how much we control the details, there are always some subtle differences from one to the next in accuracy and load development. So, if we could mitigate all of these variables and essentially come up with a barrel that wont wear out, one that would last 50,000 rounds or more, what would that barrel be worth? And is it feasible? Today's metals won't do it, even the most expensive wear resistant alloys will not hold up indefinitely. Ceramics on the other hand have shown incredible results when it comes to wear resistance. Just look at the HBN coatings that are extending barrel life; they are generally a ceramic coating filling the pores of the steel inside your barrel. Of course, it is extremely brittle right, so it would need some sub-straight work, but the concept is there. If it could be achieved, you'd have 'tires' that would never need changing and would probably see the car wear out first.

There were some military study done in the 70s that found that various types of chrome linings/steel alloys increased barrel life by 500% to 2500%, with some of them having relatively little cost increases. The caveat is that this was a test of an M134 machine gun, so the life was defined differently than we would. Still, those are some big numbers. Makes you wonder if we ought to put more effort into coatings.

To date, there are no commercial coatings that will withstand the heat. DLC and Teflon go away at temps way below what your throat reaches on firing. Even HBN needs constant re-application. It has its merits, but is dependent upon diligence and maintenance. Sooner or later, this will be overcome; someone will come up with the solution to barrel wear.

To date, there are no commercial coatings that will withstand the heat. DLC and Teflon go away at temps way below what your throat reaches on firing. Even HBN needs constant re-application. It has its merits, but is dependent upon diligence and maintenance. Sooner or later, this will be overcome; someone will come up with the solution to barrel wear.

What about a high nickel alloy like inconel 622 or 625? Is it to tough a material to overcome the challenges of drilling, reaming and rifling?

High cobalt alloy barrels have amazing life, but the problem is making them due to the hardness.

Hi,

The "problem" with barrel life advancements is that it will not come from barrel manufacturers themselves because that would kind of defeat their business of selling barrels. The advancements will first come from a coating company and then when the barrel sales drop due to a coating that will actually extend barrel life with an acceptable increase; the barrel companies will push their own advancements in the actual barrels but will do so at a drastically increased price in order to make up for the lose of quantity sold.

I don't think we are going to see barrel manufacturers leading the advancement of barrel life technologies, alloys, applications, etc etc. Just like we do not see tire manufacturers selling tires with 200k mile tread life.

Sincerely,

Theis

The "problem" with barrel life advancements is that it will not come from barrel manufacturers themselves because that would kind of defeat their business of selling barrels. The advancements will first come from a coating company and then when the barrel sales drop due to a coating that will actually extend barrel life with an acceptable increase; the barrel companies will push their own advancements in the actual barrels but will do so at a drastically increased price in order to make up for the lose of quantity sold.

I don't think we are going to see barrel manufacturers leading the advancement of barrel life technologies, alloys, applications, etc etc. Just like we do not see tire manufacturers selling tires with 200k mile tread life.

Sincerely,

Theis

What about a high nickel alloy like inconel 622 or 625? Is it to tough a material to overcome the challenges of drilling, reaming and rifling?

That is correct. I have discussed making barrels out of such materials with barrel mfg's and have cut enough Kovar and inconel myself to know that it is a lot to ask for. It is indeed tough on tools in regular machining practices. Trying to dril, ream and broach a bore in a barrel in said material; I think you'd be lucky to get through one at most, with new tooling. Quite cost inhibitive when these specialty tools cost in the thousands. Bbl mfg's expect them to last (and spread costs out) over hundreds of barrels, not just one.

What about tungsten carbide? Seems there are a lot of tools stronger/harder than milled steel made out of the stuff. It's denser than steel. It is more abrasion resistant than steel. It can take higher temperatures than steel. I think it would have orders of magnitude more life and excessive heat from powder wouldn't hardly affect it.

What about tungsten carbide? Seems there are a lot of tools stronger/harder than milled steel made out of the stuff. It's denser than steel. It is more abrasion resistant than steel. It can take higher temperatures than steel. I think it would have orders of magnitude more life and excessive heat from powder wouldn't hardly affect it.

Assuming you are referring to a cermet like tungsten carbide/cobalt, you'd face a very tough challenge to machine it, possibly tougher than an Inconel. Typically, WC/Co is cut with diamond saws, drilled with diamond-impregnated drill bits, etc. This is the reason I mentioned the ROC process in another thread on possible barrel options, but you'd have to be looking at a highly specialized need in order to justify the cost and difficulty to manufacture a tungsten carbide barrel.

I was under the impression that it wasn’t milled or machined, but cintered/molded as powder into the form, melted at thousands of degrees, and then just polished with diamond. I was thinking you could almost lost wax mold a barrel with the powder and then come back with a diamond coated button and polish the barrel...

Of course I’m totally talking out my ass with only a Wikipedia level of knowledge and have no idea.

Of course I’m totally talking out my ass with only a Wikipedia level of knowledge and have no idea.

Hi,

The "problem" with barrel life advancements is that it will not come from barrel manufacturers themselves because that would kind of defeat their business of selling barrels. The advancements will first come from a coating company and then when the barrel sales drop due to a coating that will actually extend barrel life with an acceptable increase; the barrel companies will push their own advancements in the actual barrels but will do so at a drastically increased price in order to make up for the lose of quantity sold.

I don't think we are going to see barrel manufacturers leading the advancement of barrel life technologies, alloys, applications, etc etc. Just like we do not see tire manufacturers selling tires with 200k mile tread life.

Sincerely,

Theis

Not necessarily. If you can charge more per shot for a longer lasting barrel, they could wind up making more. Especially when you conisder many rifles never get rebarelled. It all depends on costs and market prices. If you could make a 6.5x284 last for 5,000 rounds (for the sake of argumment, lets say a normal barrel will last 1000 rounds, and performance is identical), you could probably charge more than 5x the price simply because you can keep the barrel longer (maybe a whole competitive season for an high volume shooter), and not worry about wearing it out with load development. If you can do that for less than 5X the cost, you might make more money, espeically if you have a monopoly on the process. The cost part seems to be the sticking point.

I was under the impression that it wasn’t milled or machined, but cintered/molded as powder into the form, melted at thousands of degrees, and then just polished with diamond. I was thinking you could almost lost wax mold a barrel with the powder and then come back with a diamond coated button and polish the barrel...

You can do a greenware process with ROC (Rapid Omnidirectional Compaction), but we'd be talking mega-high cost just to make a small handgun barrel. Typical tungsten carbide manufacture does involve sintering, but not to near final form for a complex shape like a barrel. Thus the advent of ROC. Looking at the literature, I think ROC died the death of high cost coupled to less dollars being thrown at high tech military research. It's possible that the only surviving ROC products now are WC/Mo2C nozzles used to cut titanium.

https://www.researchgate.net/publication/234152395_Rapid_Omnidirectional_Compaction_ROC_of_Powder

One who is versed in material properties can make proper suggestions for tasks to be performed. Thus, I would not make bearings out of aluminum, nor would I make a barrel out of carbide. Carbide is very brittle and will break before it flexes. So, even it if was feasible to make a barrel this way, the only way it would stand up to the pressures incurred would be to use it as a liner. Even then, I think it would break under the load imparted by the pressure, as that is simply not containable even with restriction.

Damon's analogy is correct though; no matter what the cost is ultimately, if the value is there, then its worth it. I'd gladly pay $20K for a barrel that I would never have to change due to wear. But if it breaks because a gnat farted on it, I'm out.

Damon's analogy is correct though; no matter what the cost is ultimately, if the value is there, then its worth it. I'd gladly pay $20K for a barrel that I would never have to change due to wear. But if it breaks because a gnat farted on it, I'm out.

If it's too brittle then perhaps a metal matrix composite with a more ductile carbon steel?

I'm surprised that carbide is more brittle than a ceramic. I get it's brittle, but I would think less brittle than any ceramic...

I'm surprised that carbide is more brittle than a ceramic. I get it's brittle, but I would think less brittle than any ceramic...

If it's too brittle then perhaps a metal matrix composite with a more ductile carbon steel?

I'm surprised that carbide is more brittle than a ceramic. I get it's brittle, but I would think less brittle than any ceramic...

Thus my comments about cermets.

https://www.sciencedirect.com/topics/chemistry/cermet

https://www.explainthatstuff.com/cermets.html

One advantage of ROC is that the carbide grains do not have the heat history of traditional sintering, so the grains stay very small , typically 0.1 to 0.5 microns (sintering leads to grain growth like the big grains shown in the cartoons of the second link above). This makes ROC cermets tougher, more rigid and less brittle.

I wouldn't say that its more brittle than any ceramic, but is certainly right up there. I am by no means an expert here, just someone with hands on experience. I'd say from the above that TripleBull has a better handle on it than most.

Last edited:

I woudn't say that its more brittle than any ceramic, but is certainly right up there. I am by no means an expert here, just someone with hands on experiance. I'd say from the above that TripleBull has a better handle on it than most.

Since cermet barrels aren't practical for even the elite, properties don't really matter now anyway. Maybe years or decades down the road, manufacturing costs will come down to where they could compete. My guess is that coating or hardening processes have better shot in the near term. But current barrel tech isn't such a bad deal in terms of cost. We're talking ELR so many in this arena spend much more on all the other costs. The cost of solids to shoot out a barrel burner cost more than the barrel. There are relatively inexpensive ELR options, like 300WM with factory ammo but I think most recognize this as an expensive, chosen pursuit,

If it's too brittle then perhaps a metal matrix composite with a more ductile carbon steel?

I'm surprised that carbide is more brittle than a ceramic. I get it's brittle, but I would think less brittle than any ceramic...

I worked with some titanium metal matrix composites when I was in aerospace engineering (with boron fibers if memory serves). Granted, this was 15 years ago, but I don't think they'd work. For one thing, the matrix material is the part that would erode, so that won't help. Another is that they're extremely expensive. You can make some interesting stuff with them, but it's a specialized sort of thing, and not really the sort of thign you'd want to do with a barrel. The main benefits of MMCs is not something that really matters when making a barrel. What you really need is for the bore's surface to be extremely heat resistant, mechanically durable, and easily manufactured - a tall order. I would expect any improvemetns to come from thin liners or coatings. Perhaps very precise 3d printed liners will one day be possible, but I'm not holding my breath.

Last edited:

Similar threads

- Replies

- 7

- Views

- 2K

- Replies

- 0

- Views

- 474