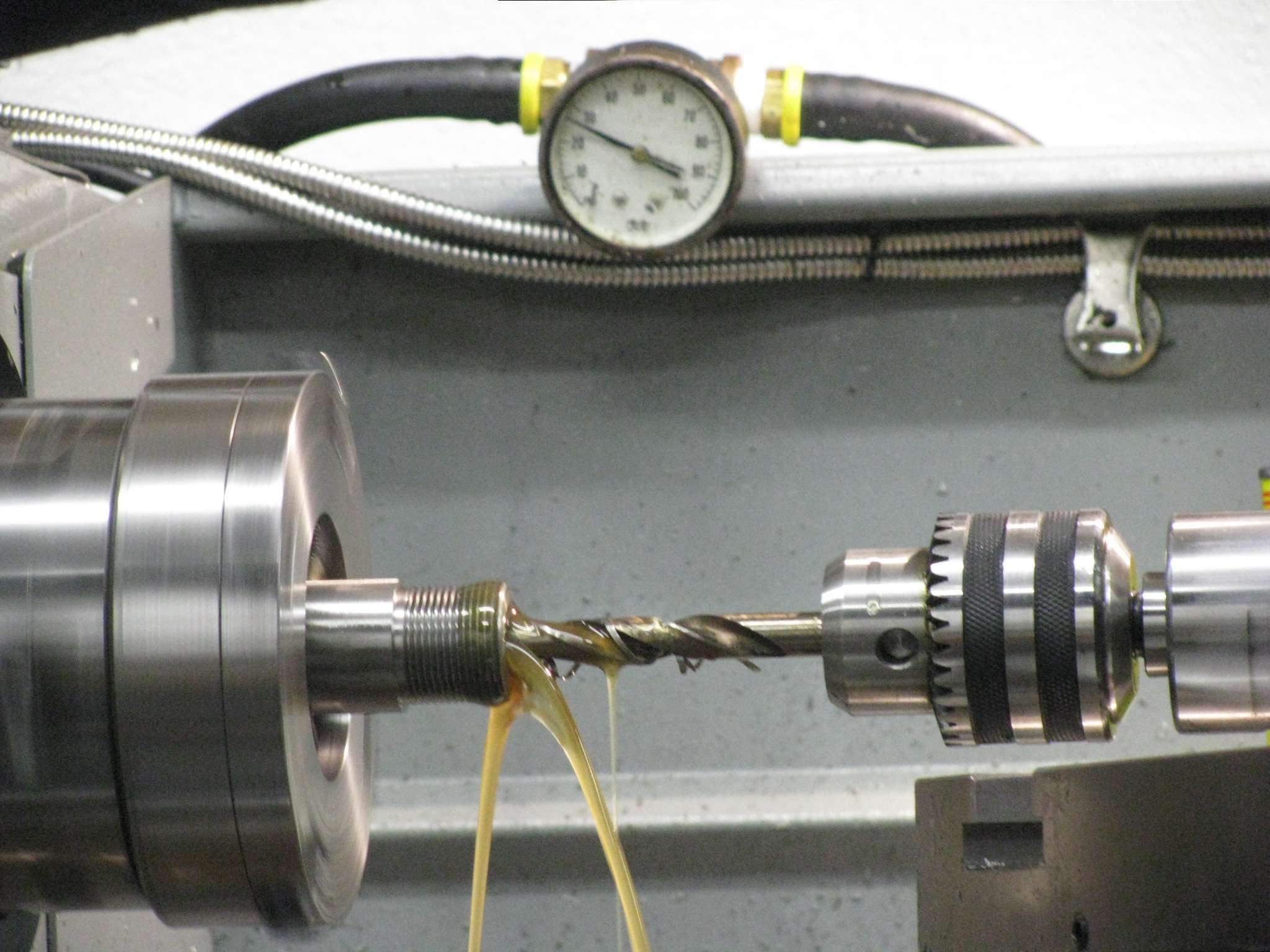

Today I was on my 8th or so cut with a new reamer and about 25 thou into a cut it does a weird snap sound and rips the handle out of my hand (hand held floating type). I pull the reamer out and one flute has a piece about 3/4" that is cleaned off to the body. It doesn't look like there is any inclusion in the steel and its a new reamer that was otherwise cutting like a mofo. I had checked the runout two passes earlier and it was running about 1 tenth......using good oil and smooth feed. Any idears?

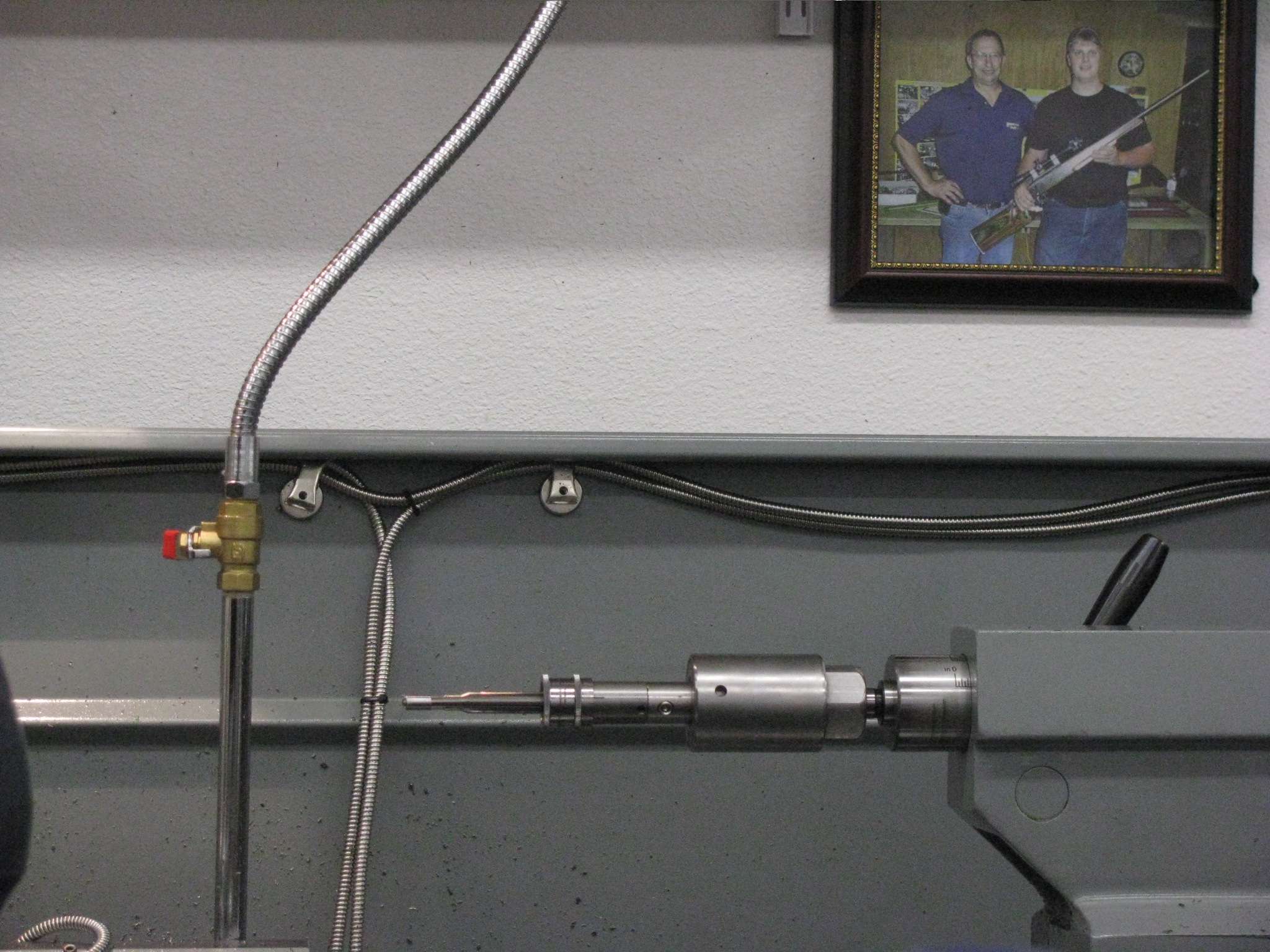

I am now looking for advice on reamer holders that don't put my hands at jeopardy as well.

No amount of asking will reveal the maker of the reamer or holder, so let's leave that out.

I am now looking for advice on reamer holders that don't put my hands at jeopardy as well.

No amount of asking will reveal the maker of the reamer or holder, so let's leave that out.