How many people are using an expander mandrel on your 6.5x47 cases? This is my first 6.5x47 and when my cases extract the case mouths get dinged up. I guess it's normal but it's making me think an expander mandrel might be beneficial. I never bothered with my .308

- Thread starter Tony1320

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

If I have a Whidden FL Bushing die, would I just remove the bushing and use the mandrel after sizing?

Forster bushing die without expander then carbide mandrel to finish it off. Great SD on my 6 Creedmoor.

If I have a Whidden FL Bushing die, would I just remove the bushing and use the mandrel after sizing?

I use a neck bushing /shoulder bump die then a expander die with a neck turning mandrel (0.002 smaller). The only possible issue I see with using a FL sizer without the expander could undersize the neck and the expander mandrel could push the neck and deform the shoulder. If you use the correct neck bushing you should be fine without the expander ball.

ThisForster bushing die without expander then carbide mandrel to finish it off. Great SD on my 6 Creedmoor.

So you guys run them through the FL bushing die then through the expander after? I thought you ran it through before sizing

What bushing do you guys use for 6.5x47 if you use an expander mandrel? Right now I have a .288 bushing and loaded round is .290

What bushing do you guys use for 6.5x47 if you use an expander mandrel? Right now I have a .288 bushing and loaded round is .290

So you guys run them through the FL bushing die then through the expander after? I thought you ran it through before sizing

What bushing do you guys use for 6.5x47 if you use an expander mandrel? Right now I have a .288 bushing and loaded round is .290

If you ran it through before sizing it wouldn’t do anything. It would pass through untouched. You have to size it down so that the mandrel can then open it back up.

Try it with what you have, you may find it works well. Typically with a .290” neck diameter you would want to take it down to .287 so that the mandrel can open it back up to .288. But your bushing and spring back could mean what you have now is just fine.

If you ran it through before sizing it wouldn’t do anything. It would pass through untouched. You have to size it down so that the mandrel can then open it back up.

Try it with what you have, you may find it works well. Typically with a .290” neck diameter you would want to take it down to .287 so that the mandrel can open it back up to .288. But your bushing and spring back could mean what you have now is just fine.

Which mandrel does everyone use? I was looking at the 21st century titanium one

Do you guys lube your necks when running through a mandrel?

I use sinclair. There was a mandrel thread a few months back with lots of info.

Carbon left in the neck lubes enough for carbide mandrel. With steel mandrel I lightly lube every few cases.

Carbon left in the neck lubes enough for carbide mandrel. With steel mandrel I lightly lube every few cases.

I squeeze my necks down .004 under loaded neck diameter using a Redding Neck bushing die or a honed Forster FL die if I'm also bumping the shoulder. I then run them through a 21st Century TiN Turning mandrel which opens the neck back up .002 resulting in .002 neck tension. (Warning the expander mandrels only open the necks up .001 thats why most of us use the Turning mandrel)

Using a non honed FL sizing die is kinda pointless because if you take measurements after sizing brass with the expander removed that die is squeezing the neck down an extremely unnecessary amount. Before honing mine would squeeze the neck down .009 - .012 depending on caliber. If you aren't going to have it honed you should just leave the expander ball in and forget the mandrel. Forster does this so the die works with all kinds of brass which vary in neck thickness.

With a neck bushing or FL neck bushing die you can swap bushings out till you find the necks are being squeezed down to the exact measurement you want. The point of using a mandrel is A) to size the necks minimal to prevent overworking your brass which in turn extends brass life and B) for concentricity.

Using a non honed FL sizing die is kinda pointless because if you take measurements after sizing brass with the expander removed that die is squeezing the neck down an extremely unnecessary amount. Before honing mine would squeeze the neck down .009 - .012 depending on caliber. If you aren't going to have it honed you should just leave the expander ball in and forget the mandrel. Forster does this so the die works with all kinds of brass which vary in neck thickness.

With a neck bushing or FL neck bushing die you can swap bushings out till you find the necks are being squeezed down to the exact measurement you want. The point of using a mandrel is A) to size the necks minimal to prevent overworking your brass which in turn extends brass life and B) for concentricity.

Last edited:

I use the 21st Century TiN-coated mandrels and don't go out of my way to lube the inside of the necks before expanding... but the way that I lube my cases for resizing sometimes gets some lube in the case mouth anyhow. I have also run them dry and not had any problems.

The way that I use the expander mandrels is that I remove the decap pin (and therefore the expander ball as well) from my Forster FL dies and run the cases through external resizing, then run them through neck/mouth expansion using the appropriate mandrel. Decapping is done with a universal decapping die as the first step in the case prep process (second step is a ride in the tumbler to clean the cases).

The way that I use the expander mandrels is that I remove the decap pin (and therefore the expander ball as well) from my Forster FL dies and run the cases through external resizing, then run them through neck/mouth expansion using the appropriate mandrel. Decapping is done with a universal decapping die as the first step in the case prep process (second step is a ride in the tumbler to clean the cases).

If you use the turning mandrel you should have 0.002 neck tension. Example a 6mm/.243 turning mandrel should measure 0.241. The idea is to size the neck down slightly below this with a bushing and then slightly open it back up. The mandrel should just kiss the inside of the neck.Thanks for all the info guys

What does the neck measure after running them through a 21st Century TiN expander mandrel?

Thanks for all the info guys

What does the neck measure after running them through a 21st Century TiN expander mandrel?

This actually depends on how much you squeeze the neck down first.

This actually depends on how much you squeeze the neck down first.

Oh ok

So if my round measures .290 loaded you would use a .286 bushing and the turning mandrel would open it up to .288?

I'm using a .288 bushing now without an expander I would want to go to a .286 bushing is that right?

I want to make sure I order the right components

Thanks

Does anyone use neck turning mandrels with normal fl dies with decap/expander removed? Im about to use Forster for a couple calibers for the first time, everything else has been Redding bushing dies. Question is should I be concerned with overworking the brass (since I assume it’s making a tighter neck tension during sizing vs bushing dies) or is it just as bad as using the expander ball and wouldn’t be a benefit.

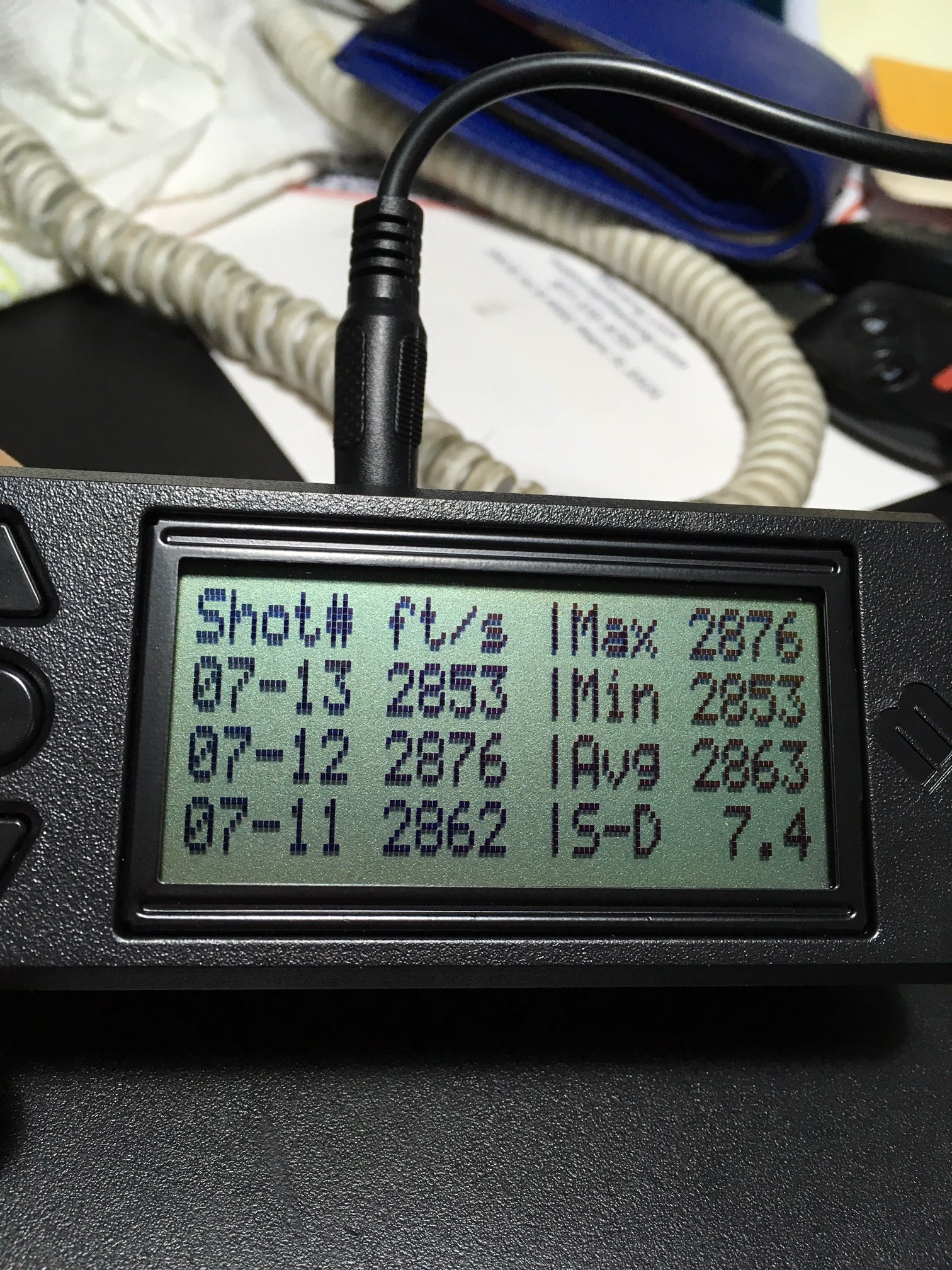

I use the Sinclair Carbide Turning Mandrel and today shot a test string of 6.5x47L it was 95 degree when it was shot today.

Nice.

Does anyone use neck turning mandrels with normal fl dies with decap/expander removed? Im about to use Forster for a couple calibers for the first time, everything else has been Redding bushing dies. Question is should I be concerned with overworking the brass (since I assume it’s making a tighter neck tension during sizing vs bushing dies) or is it just as bad as using the expander ball and wouldn’t be a benefit.

Yes, that's the same setup I use. Forster FL dies with the guts removed, separate expander mandrel with the 0.002 turning mandrel.

If you are worried about overworking the brass you can have Forster hone the neck to make it a bit larger, you would want to be about 0.004 smaller than the neck OD of a loaded round.

If you neck turn your brass that would be the way to go. If you don’t NT then you would be over sizing some brass and maybe under sizing some. The thickness of brass in the neck area varies between brands and even different lots.

Whidden Bushing sizer die without the decap/expander, then a Sinclair expander mandrel 0.002. More flexibility with the bushing for different brass brands.

Does anyone use neck turning mandrels with normal fl dies with decap/expander removed? Im about to use Forster for a couple calibers for the first time, everything else has been Redding bushing dies. Question is should I be concerned with overworking the brass (since I assume it’s making a tighter neck tension during sizing vs bushing dies) or is it just as bad as using the expander ball and wouldn’t be a benefit.

I have a non bushing Redding fl die with the decap and expanded removed. I’ve been told that’s the way to go from since there’s no need to spend the extra money on bushing dies if I’m just going to use my mandrel after. I’m sure it works the brass slightly more, but I was told it doesn’t really effect it too much. I have no clue if that was just broscience on how they know it doesn’t cause “too much” over working. I have yet to see any issues, nor have the people who explain it to me.

You won’t be working the brass any more with the mandrel than you would with the expander button in the die. As far as concentricity goes if the brass is not the same thickness all the way around, it will expand more in the thin spots. Annealing makes the brass more pliable and expands more evenly. You have to work the brass to use it. Just try to do it in as few step and increments as possible.

My experience with using a mandrel in standard size dies vs honed dies. If you are sizing down the brass with a standard die, you may see a neck diameter that is 0.004 to 0.006+ smaller than it will be after mandrel sizing. WIth a honed die you are only expanding 0.001 or 0.002. I found that with the larger amount of expansion I needed to be more diligent about inside neck lube, and that it seemed to scrub more of the carbon off the inside of the neck (I corn cob tumble). Press effort is a bit higher, and the net neck tension is also higher since you've work hardened the brass more.

Not that the end results on target were any different, just observations. For me having the honed die and working the brass less seems to be a smoother workflow overall.

Not that the end results on target were any different, just observations. For me having the honed die and working the brass less seems to be a smoother workflow overall.

Absolutely. The smaller the increments in size change the better the outcome.My experience with using a mandrel in standard size dies vs honed dies. If you are sizing down the brass with a standard die, you may see a neck diameter that is 0.004 to 0.006+ smaller than it will be after mandrel sizing. WIth a honed die you are only expanding 0.001 or 0.002. I found that with the larger amount of expansion I needed to be more diligent about inside neck lube, and that it seemed to scrub more of the carbon off the inside of the neck (I corn cob tumble). Press effort is a bit higher, and the net neck tension is also higher since you've work hardened the brass more.

Not that the end results on target were any different, just observations. For me having the honed die and working the brass less seems to be a smoother workflow overall.

I use an expander mandrel to smear graphite into the pores of the case neck wall. This helps to make bullet release consistent in stainless tumbled brass. It cut my ES/SD in half.

I use an expander mandrel to smear graphite into the pores of the case neck wall.

Interesting... how are you applying it?

Dip the case neck in the imperial media and then run it over the mandrelInteresting... how are you applying it?

Dip the case neck in the imperial media and then run it over the mandrel

Hmm... so after lubing and sizing, you're cleaning the lube off, then dipping the neck in the ceramic media w/ dry graphite, *then* expanding? Presumably followed by primer, powder, seating? Do you wipe off the outsides of the necks after dipping in the media? When I tried the stuff in the past, it always seemed like I got more on the outside of the neck/shoulder than I ever did inside, where it counted.

IDK his specific order of operation, Ill let him explain his personal process.

When I have done it (I dont stainless clean at all, I vibrate) but I would tumble the case for an initial cleaning, spray lube the outside, size the case down, tumble to get that wet lube off and then dip the case neck in graphite before I ran it over the mandrel. I didnt clean the graphite off (other than what got all over my fingers).

The graphite powder shouldnt compromise the powder integrity like wet lubes can so theres no real "need" to clean them again other than keeping your fingers clean of the black gunk.

I stopped using it because I didnt like the black gunk so now I just intentionally spray lube inside the case neck now and do both the sizing and mandrel operations before I clean any lube off at all.

People also graphite the case neck and/or bullet before seating as well, I can verify that it has made hard seating combinations much easier to seat bullets.

When I have done it (I dont stainless clean at all, I vibrate) but I would tumble the case for an initial cleaning, spray lube the outside, size the case down, tumble to get that wet lube off and then dip the case neck in graphite before I ran it over the mandrel. I didnt clean the graphite off (other than what got all over my fingers).

The graphite powder shouldnt compromise the powder integrity like wet lubes can so theres no real "need" to clean them again other than keeping your fingers clean of the black gunk.

I stopped using it because I didnt like the black gunk so now I just intentionally spray lube inside the case neck now and do both the sizing and mandrel operations before I clean any lube off at all.

People also graphite the case neck and/or bullet before seating as well, I can verify that it has made hard seating combinations much easier to seat bullets.

Hmm... so after lubing and sizing, you're cleaning the lube off, then dipping the neck in the ceramic media w/ dry graphite, *then* expanding? Presumably followed by primer, powder, seating? Do you wipe off the outsides of the necks after dipping in the media? When I tried the stuff in the past, it always seemed like I got more on the outside of the neck/shoulder than I ever did inside, where it counted.

Taking a clean case, the first thing I do is neck size using a Lee collet neck die. Then I apply Imperial sizing wax and size in a Redding body die. Then I wipe off the lube and lightly chamfer the case mouth. Then I dunk the case neck into Imperial ceramic media with graphite and run it into the mandrel die. This expands the neck and forces the graphite into the neck walls. I then wipe off the graphite from the outside of the neck. Then prime, charge, and seat.

For tactical and hunting rifles that I eject brass in and get case mouth's dinged up I have found that using a Lee collet die works best. I set the die to barely reduce the neck diameter so that it just makes the necks round again. It also deprimes at the same time so I'm ready to clean.

The Lee Collet Die is what I use to resize the necks on my cases. Use a Wilson F/L bushing die w/o the bushing to size the rest. I like the Lee because of not having to lube the necks and size the neck 1 time and through. Instead of sizing too much and having to expand to get the size I need.For tactical and hunting rifles that I eject brass in and get case mouth's dinged up I have found that using a Lee collet die works best. I set the die to barely reduce the neck diameter so that it just makes the necks round again. It also deprimes at the same time so I'm ready to clean.

I like the idea of imbedding the graphite into the brass in the neck. Should make long term storage better by keeping the bullets from adhering to the necks and stabilize neck tension. Stored rounds should have same tension as newly loaded ones.Taking a clean case, the first thing I do is neck size using a Lee collet neck die. Then I apply Imperial sizing wax and size in a Redding body die. Then I wipe off the lube and lightly chamfer the case mouth. Then I dunk the case neck into Imperial ceramic media with graphite and run it into the mandrel die. This expands the neck and forces the graphite into the neck walls. I then wipe off the graphite from the outside of the neck. Then prime, charge, and seat.

I also using Sinclair expander die.on all my carliber...run fl without expander ball and use expander die as follows Sinclair only makes 001 less than bullet diam (i use this for virgin brass)expander mandrel or 002 less neck turn mandrell.i use nk mandrell as i want 2 thousand neck tension..

For my x47 i use 288 bushings and its barely 002 neck tension and nk mandrell pass trough without over working brass and no need for lube inside necks.you can dp 286 but i would lube neck you might move shoulder or headspace on brass being too much resistance

For my x47 i use 288 bushings and its barely 002 neck tension and nk mandrell pass trough without over working brass and no need for lube inside necks.you can dp 286 but i would lube neck you might move shoulder or headspace on brass being too much resistance

The way that I use the expander mandrels is that I remove the decap pin (and therefore the expander ball as well) from my Forster FL dies and run the cases through external resizing, then run them through neck/mouth expansion using the appropriate mandrel. Decapping is done with a universal decapping die as the first step in the case prep process (second step is a ride in the tumbler to clean the cases).

Exactly as I do as well.

jsthntn, how high is the DIP rail over the bbl? I ask because I want to mount a scope with 30mm body and 50mm objective. If you are using a 30 mm scope body, what height rings did you use?

Thanks

For tactical and hunting rifles that I eject brass in and get case mouth's dinged up I have found that using a Lee collet die works best. I set the die to barely reduce the neck diameter so that it just makes the necks round again. It also deprimes at the same time so I'm ready to clean.

Should have said that I do this just to recap and round the case mouths. I do Norma case prep and Fl resize with a bushing die before loading

So I've been using an expander mandrel for a few years now and I'm running into an odd issue. I've been using the expander for .223, .308, and 6.5 Creedmoor and only see this issue on 6.5 Creedmoor.

I'm using Peterson brass, Whidden dies, and the Sinclair expander with carbide mandrel. After FL sizing using Redding's imperial case wax, I use a q-tip and get some lube inside the case necks prior to running them in the expander. When the expander is clean, it works fine, but after expanding a few necks it starts to bind up. If I don't clean the expander after every 2 or 3 cases- I run the risk of destroying the case on the down stroke. If I don't apply lube, I'll definitely destroy the case on the downstroke. The odd thing is this doesn't happen on .223 or .308 and they go through the expander with ease and probably don't even need lube. I measured the mandrel with my calipers and it's showing 0.264 inches so is it possible I got an out of spec mandrel? Any ideas what I'm doing wrong with the 6.5 Creedmoor then?

I'm using Peterson brass, Whidden dies, and the Sinclair expander with carbide mandrel. After FL sizing using Redding's imperial case wax, I use a q-tip and get some lube inside the case necks prior to running them in the expander. When the expander is clean, it works fine, but after expanding a few necks it starts to bind up. If I don't clean the expander after every 2 or 3 cases- I run the risk of destroying the case on the down stroke. If I don't apply lube, I'll definitely destroy the case on the downstroke. The odd thing is this doesn't happen on .223 or .308 and they go through the expander with ease and probably don't even need lube. I measured the mandrel with my calipers and it's showing 0.264 inches so is it possible I got an out of spec mandrel? Any ideas what I'm doing wrong with the 6.5 Creedmoor then?

I measured 5 cases from each step and here are the corresponding outer neck diameters. So looks like the expander is putting about 4 thousands of expansion on the case neckAre you sizing your necks down too much before opening them up with the mandrel??

Fired cases neck: .297

FL Sized neck: .285

Expanded Neck: .289

Not excessive opening up 0.004.... I squeeze all mine down so I'm only opening them up 0.002 but I don't think 0.004 is the cause.... I could be wrong

Clean necks? Chamfer/debur??

I've never had this problem with my 21st Centruy TiN mandrel and don't need lube

They are chamfered and deburred. Cleaning could be it, but I usually tumble my brass prior to sizing. I’ll try doing another batch of 10 and clean them significantly more as a test and maybe brush the inside of the necks and see what happens.

Just find it interesting that this doesn’t happen on the other 2 cartridges that I reload. Process is damn near the same. If that doesn’t work, I might try and order a different mandrel.

They are chamfered and deburred. Cleaning could be it, but I usually tumble my brass prior to sizing. I’ll try doing another batch of 10 and clean them significantly more as a test and maybe brush the inside of the necks and see what happens.

Just find it interesting that this doesn’t happen on the other 2 cartridges that I reload. Process is damn near the same. If that doesn’t work, I might try and order a different mandrel.

If you have a SS mandrel maybe it needs polished up? Idk I've been using TiN coated mandrels for years and they size like butter

I am using the TiN expanders as well and never use lube. Im also only sizing the necks so the expander has to open them up a few thousandths.

Similar threads

- Replies

- 139

- Views

- 4K