This project came about because it is difficult to get repeat headspace measurements that are reasonably close using Hornady’s Stoney Point gauge designed for measuring headspace in a gas gun. It is the right angle bend through which the not so flexible wire is pushed to seat the bullet against the lands supposedly with the same finger pressure each time that is the problem. The straight Stoney Point gauge sold for use in a bolt gun is easy to seat with the same finger pressure each time and there is far less variation in the measurements. It seats with a straight nylon rod in a straight tube. Unfortunately it is about inch too short to use in a gas gun.

I added two inches to the length of the straight Stoney Point gauge. The only tools needed were a hacksaw, black wet to dry sandpaper and epoxy or super glue for use with metal. The difficult to locate item was a metal tube to use for a splice. Because the shaft of the Stoney Point gauge is 0.370”, the metal splice tubing with the closest fit would be 10mm OD and have 0.3mm walls. This would gave a ID diameter of 9.4mm which is 0.370”. That is cutting it close. This was a easy to find eBay item. There is wide variation in price so just watch awhile if necessary. Also be prepared to wait a couple months for the less expensive to get here.

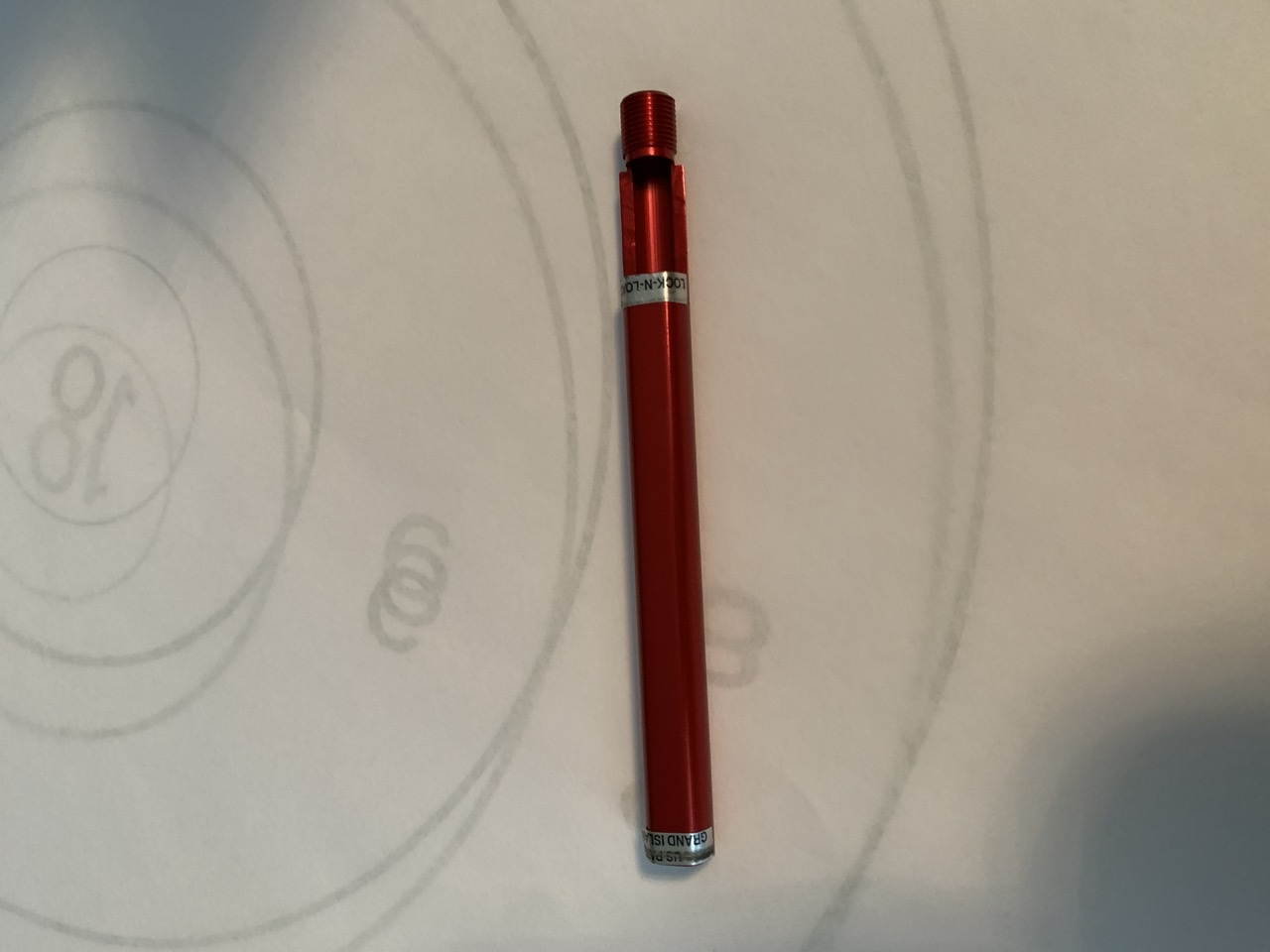

I cut the splice tubing to 8”. I cut the straight Stoney Point gauge literally In half. See the following picture for all the parts. One Shaft end has already been slipped into the splice tube.

I next used several small shim pieces cut from the Hornady logo that was stuck on the shaft and put them in several places to assure that the pieces would be in the same orientation since there was some slight play. I then withdrew the shaft from the tube being careful not to dislodge the shim, laid down beads of super glue and reinserted to predrawn marks indicating how far to insert to leave the 2” extension in the middle where there was no shaft. See the following picture for the shim positioning:

And the following for the completed gauge:

Now it extends sufficient to use in a gas gun:

I know, I probably have too much time on my hands as I shelter at home. Anyone else with projects that fall in this category?

I added two inches to the length of the straight Stoney Point gauge. The only tools needed were a hacksaw, black wet to dry sandpaper and epoxy or super glue for use with metal. The difficult to locate item was a metal tube to use for a splice. Because the shaft of the Stoney Point gauge is 0.370”, the metal splice tubing with the closest fit would be 10mm OD and have 0.3mm walls. This would gave a ID diameter of 9.4mm which is 0.370”. That is cutting it close. This was a easy to find eBay item. There is wide variation in price so just watch awhile if necessary. Also be prepared to wait a couple months for the less expensive to get here.

I cut the splice tubing to 8”. I cut the straight Stoney Point gauge literally In half. See the following picture for all the parts. One Shaft end has already been slipped into the splice tube.

I next used several small shim pieces cut from the Hornady logo that was stuck on the shaft and put them in several places to assure that the pieces would be in the same orientation since there was some slight play. I then withdrew the shaft from the tube being careful not to dislodge the shim, laid down beads of super glue and reinserted to predrawn marks indicating how far to insert to leave the 2” extension in the middle where there was no shaft. See the following picture for the shim positioning:

And the following for the completed gauge:

Now it extends sufficient to use in a gas gun:

I know, I probably have too much time on my hands as I shelter at home. Anyone else with projects that fall in this category?

Last edited: