I recently start working on the load development for hornady 195ELD bullet using Varget.

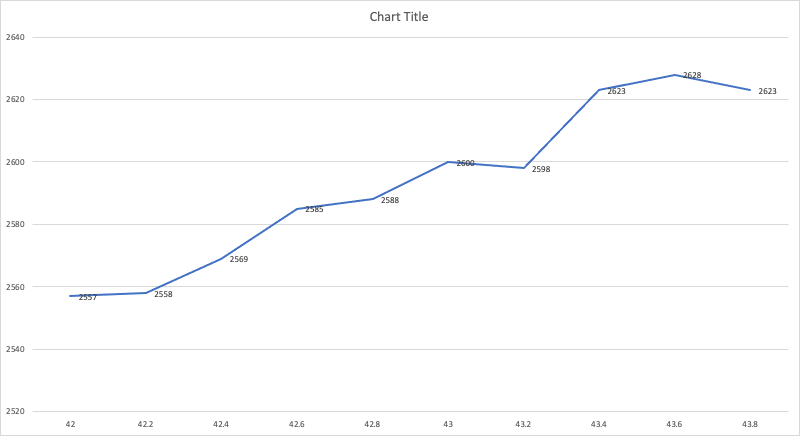

It seems there are multiple flat points can be used for the ideal powder charge from the chart below.

a. 42.0-42.2

b. 42.6-42.8

c. 43.0-43.2

d. 43.4-43.8

My questions are:

1. Does the chart with multiple flat points look normal to you?

2. Should I test for each one of the load ranges above to find the lowest SD and ES?

3. If yes to question 2 above e.g. 43.0-43.2, should I do 5 shot groups for powder charge at 43.0, 43.1 and 43.2 to find out the best charge with lowest SD and ES, then work on the seating depth next for group size?

Thank you.

It seems there are multiple flat points can be used for the ideal powder charge from the chart below.

a. 42.0-42.2

b. 42.6-42.8

c. 43.0-43.2

d. 43.4-43.8

My questions are:

1. Does the chart with multiple flat points look normal to you?

2. Should I test for each one of the load ranges above to find the lowest SD and ES?

3. If yes to question 2 above e.g. 43.0-43.2, should I do 5 shot groups for powder charge at 43.0, 43.1 and 43.2 to find out the best charge with lowest SD and ES, then work on the seating depth next for group size?

Thank you.