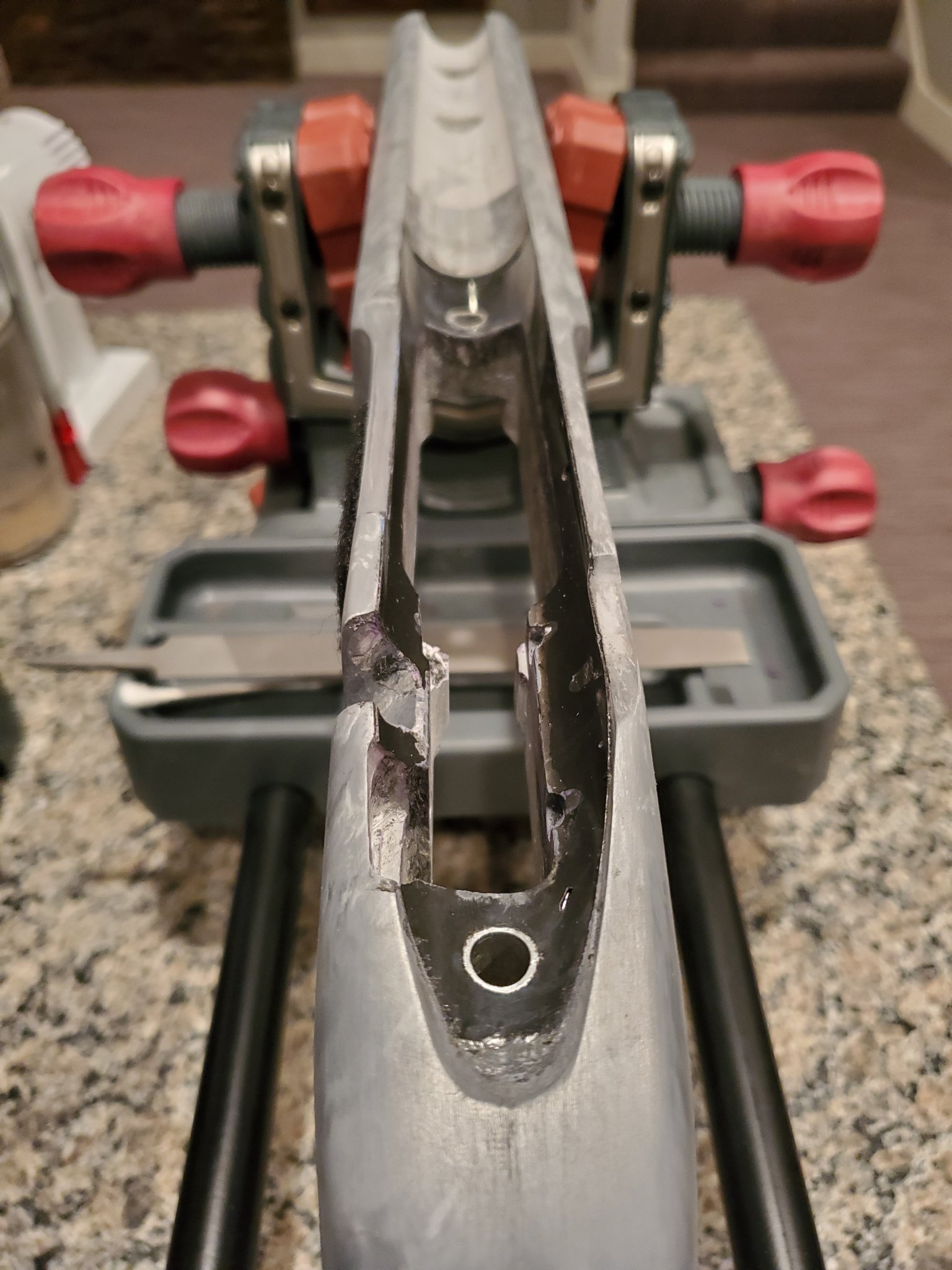

I just finished my first bedding job (full length) using Marine Tex Gray and McLube 1700 as the release agent. Pics are below.

In some respects, I thought it actually went ok. I didn't glue my stock to my action, and most of the lines turned out fairly clean, although I did have a couple of areas where I had to clean up, and I did get some voids. There were also some very thin spots around the various contours (mag & trigger wells, pillars, etc.) since I didn't grind into them all the way to the edge. The biggest heartbreak, though, was the rear recoil lug recess... that just looks like a straight mess. I think I might have to try that again, since that's one of the most functional parts and unless I'm misunderstanding, this isn't going to cut it for accuracy purposes (which is the whole reason I did this). Any idea what I can do next time to avoid that?

In some respects, I thought it actually went ok. I didn't glue my stock to my action, and most of the lines turned out fairly clean, although I did have a couple of areas where I had to clean up, and I did get some voids. There were also some very thin spots around the various contours (mag & trigger wells, pillars, etc.) since I didn't grind into them all the way to the edge. The biggest heartbreak, though, was the rear recoil lug recess... that just looks like a straight mess. I think I might have to try that again, since that's one of the most functional parts and unless I'm misunderstanding, this isn't going to cut it for accuracy purposes (which is the whole reason I did this). Any idea what I can do next time to avoid that?