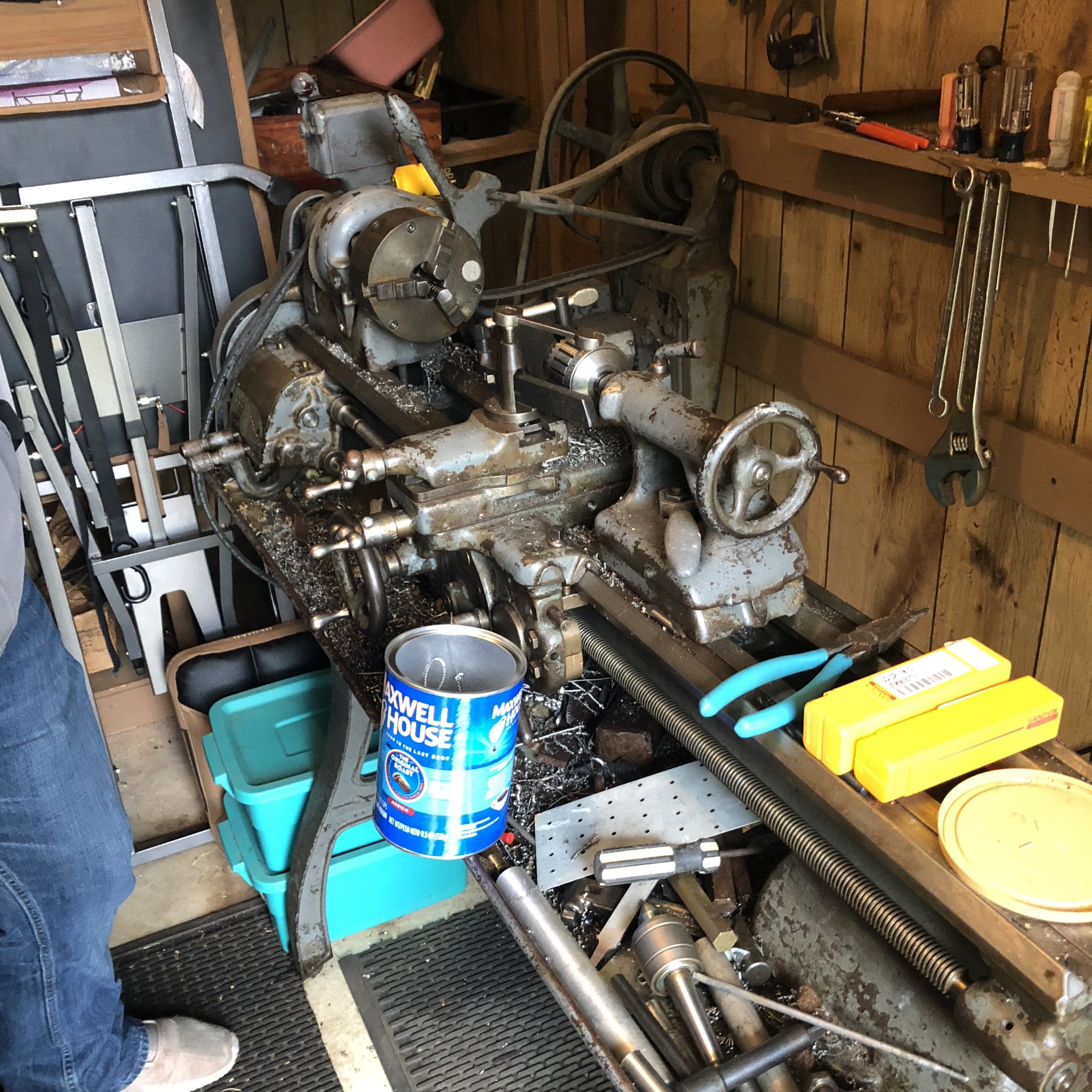

I recently inherited my uncles South Bend 9A 48" lathe and moved to the house from his place in Central Alabama.

Since the lathe isn't terribly heavy the moving process was pretty easy compared to what it could have been.

It was pretty manky, but a little bit of time cleaning out the chips and some oil and she want to run pretty nicely now.

I got a buttload of lathe tooling, mill cutters and machinist tools when I cleaned out that part of his shed.

My cousins and aunt were pretty happy to have that stuff gone as they weren't metal workers at all.

I bought a new Tikka CTR with a 24" barrel in December of '18 and fitted an Area 419 Hellfire Gunsmith Fit Brake to the barrel ( it was factory threaded 5/8"-24 )

The OD at the rear needed to be tapered to get it close to the barrel OD and then timed.

I did find out the the last couple of threads on the muzzle of a Tikka need a few extra thousandths of counterbore so that the rear face of the brake will seat on the barrel shoulder and not bottom on the treads.

I got it timed up, the taper looks good and got some valuable experience with my new -to- me WWII vintage lathe in how to run it and some of the speeds and feeds for a low HP manual lathe.

Since the lathe isn't terribly heavy the moving process was pretty easy compared to what it could have been.

It was pretty manky, but a little bit of time cleaning out the chips and some oil and she want to run pretty nicely now.

I got a buttload of lathe tooling, mill cutters and machinist tools when I cleaned out that part of his shed.

My cousins and aunt were pretty happy to have that stuff gone as they weren't metal workers at all.

I bought a new Tikka CTR with a 24" barrel in December of '18 and fitted an Area 419 Hellfire Gunsmith Fit Brake to the barrel ( it was factory threaded 5/8"-24 )

The OD at the rear needed to be tapered to get it close to the barrel OD and then timed.

I did find out the the last couple of threads on the muzzle of a Tikka need a few extra thousandths of counterbore so that the rear face of the brake will seat on the barrel shoulder and not bottom on the treads.

I got it timed up, the taper looks good and got some valuable experience with my new -to- me WWII vintage lathe in how to run it and some of the speeds and feeds for a low HP manual lathe.