Hi,

I'm not sure who else to ask about this but am sure someone out there will have some helpful insight.

I recently purchased a Weatherby Mark V Weathermark LT chambered in 6.5 Creedmoor. It shoots great and give me tight groups considering I have only shot for about a year.

However, it is giving me two problems that I can't seem to figure out. I have asked a couple friends that reload and a gunsmith about it with no concrete answers. Everything checks out as far as I can tell... The gunsmith checked firing pin protrusion and said that it was to spec (0.052") and he thought it could be a headspacing issue?

Here is the email that I sent to Weatherby yesterday:

I recently purchased a Weatherby Mark V Weathermark LT. It is a great rifle and I can't wait to hunt with it this fall.

However, after shooting a handful of factory rounds and handloads through the rifle, it has me concerned. There are two main issues:

1. Both factory ammo and handloads (loaded with the starting load from Hornady Manual) are showing high pressure signs. Specifically flattened primers.

2. Every fired case comes out with a distinct repeatable scratch. I have no idea what this is and if it is of concern.

I will attach photos below and would really appreciate some input/advice on the issues I am encountering.

A photo of a very flattened and cratered primer from factory Hornady ammo.

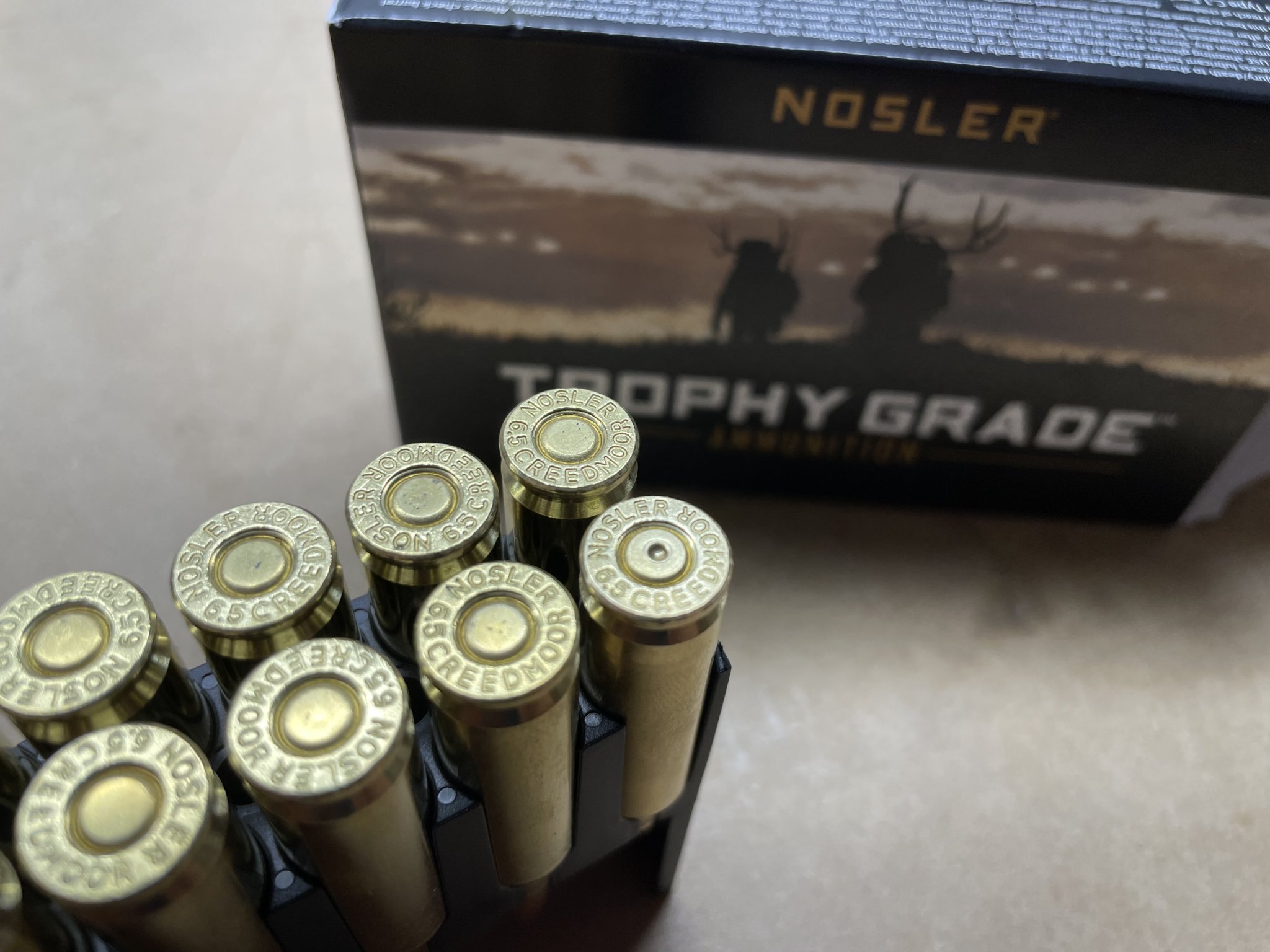

A photo of factory Nosler Ammo showing similar cratering

This is a photo of my hand loads.

Starting grain from the hornady reloading manual.

(Winchester brass (new), Winchester Large Rifle Primer, Hornady Match 140 gr bullet, 36gr of H4350 Powder, Seated 0.025" off the lands)

A photo of the scratches that are on every fired case. On the shoulder and the neck. Same scratch every time.

This is a 38 gr load of the same hand load. It is more flattened still...

Any input or thoughts would be greatly appreciated. If there is a better place to share this post, please let me know so that I can it to the right people.

Thanks!

I'm not sure who else to ask about this but am sure someone out there will have some helpful insight.

I recently purchased a Weatherby Mark V Weathermark LT chambered in 6.5 Creedmoor. It shoots great and give me tight groups considering I have only shot for about a year.

However, it is giving me two problems that I can't seem to figure out. I have asked a couple friends that reload and a gunsmith about it with no concrete answers. Everything checks out as far as I can tell... The gunsmith checked firing pin protrusion and said that it was to spec (0.052") and he thought it could be a headspacing issue?

Here is the email that I sent to Weatherby yesterday:

I recently purchased a Weatherby Mark V Weathermark LT. It is a great rifle and I can't wait to hunt with it this fall.

However, after shooting a handful of factory rounds and handloads through the rifle, it has me concerned. There are two main issues:

1. Both factory ammo and handloads (loaded with the starting load from Hornady Manual) are showing high pressure signs. Specifically flattened primers.

2. Every fired case comes out with a distinct repeatable scratch. I have no idea what this is and if it is of concern.

I will attach photos below and would really appreciate some input/advice on the issues I am encountering.

A photo of a very flattened and cratered primer from factory Hornady ammo.

A photo of factory Nosler Ammo showing similar cratering

This is a photo of my hand loads.

Starting grain from the hornady reloading manual.

(Winchester brass (new), Winchester Large Rifle Primer, Hornady Match 140 gr bullet, 36gr of H4350 Powder, Seated 0.025" off the lands)

A photo of the scratches that are on every fired case. On the shoulder and the neck. Same scratch every time.

This is a 38 gr load of the same hand load. It is more flattened still...

Any input or thoughts would be greatly appreciated. If there is a better place to share this post, please let me know so that I can it to the right people.

Thanks!