Curious if anyone uses them and / or has any experience with them? Any alternatives to using them specifically for 22 & 30 caliber tips. I’m finding I’m getting inconsistent seating depth currently with the “standard” stem.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Forster custom polished seating stems

- Thread starter simonp

- Start date

Tell us what you mean by "getting inconsistent seating depth..."

I am going to suggest a concept that the purpose of a custom or polished seating stem, is to reduce the contact stress on a bullet jacket when it doesn't fit a regular stem, but more importantly that you may need to broaden your search for the root cause of the inconsistency.

I am going to suggest a concept that the purpose of a custom or polished seating stem, is to reduce the contact stress on a bullet jacket when it doesn't fit a regular stem, but more importantly that you may need to broaden your search for the root cause of the inconsistency.

Inconsistent in the sense that if I load 20 rounds in identical length pieces of brass and then measure OAL I will get 10 or more different measurements, generally more. If it was a thousandth of a difference I’d probably accept it but I’m seeing differences of up to 10-15 thousandths

Because there is such a difference in bullets OAL, measuring seating depth by COAL isn't going to give you any good indication of your seating depth. So, it sounds like it's not really an issue about your seating stem. The only thing I've had to do with my seating stem was to do a little polishing with lapping compound so that the seating stem didn't leave a telltale ring on the ogive.Inconsistent in the sense that if I load 20 rounds in identical length pieces of brass and then measure OAL I will get 10 or more different measurements, generally more. If it was a thousandth of a difference I’d probably accept it but I’m seeing differences of up to 10-15 thousandths

To get really consistent seating depths, I sort my bullets using a comparator insert that has the same diameter as my seating stem contact point. It's that seating stem contact point that controls your seating depth, not the base to bullet's meplat (OAL) or the standard base to ogive measurement. The standard BTO measurement can give you less variation in seating depth than any OAL. That seating stem contact point is the key.

Are you using a mandrel prior to seating?? Annealing? Any sort of lube (think graphite) on the inside of the necks?Measuring to the ogive with SMK bullets

Are you using a mandrel prior to seating?? Annealing? Any sort of lube (think graphite) on the inside of the necks?

Yes using a mandrel and graphite in the necks for lube.

Not annealing yet

Okay, here I think you mean that you measure CBTO, cartridge base to ogive since the tips of most match bullets are known to be rough and inconsistent.Inconsistent in the sense that if I load 20 rounds in identical length pieces of brass and then measure OAL I will get 10 or more different measurements, generally more. If it was a thousandth of a difference I’d probably accept it but I’m seeing differences of up to 10-15 thousandths

I agree getting a range of 0.015" in seating depths is a sign that something is wrong.

By chance, is your load at compression levels? Do you hear or feel a crunch when you seat?

If you prep and load a sample of dummy rounds without powder, do they also vary?

Having a bullet base crunch down on a powder column is known to create issues like this.

A custom seating stem can help when a regular one leaves marks on the bullet surface because the contact pressure is too high, but I doubt very much you would see a huge improvement in seating depth from a stem alone. Are your seating forces higher than normal? By chance, do you have a measurement in pounds for the seating force like in the case of a K&M Arbor with a Force Pack or from a AMP Press?

Those forces would tell us if we are really in the ballpark of a seating stem pressure problem, or some other root cause like compression on the powder.

new seating stem probably wont help much. you have too many flex in cartridge, die and press.

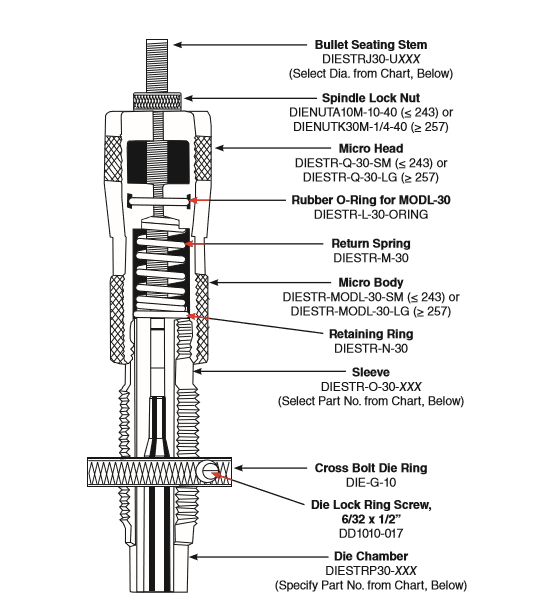

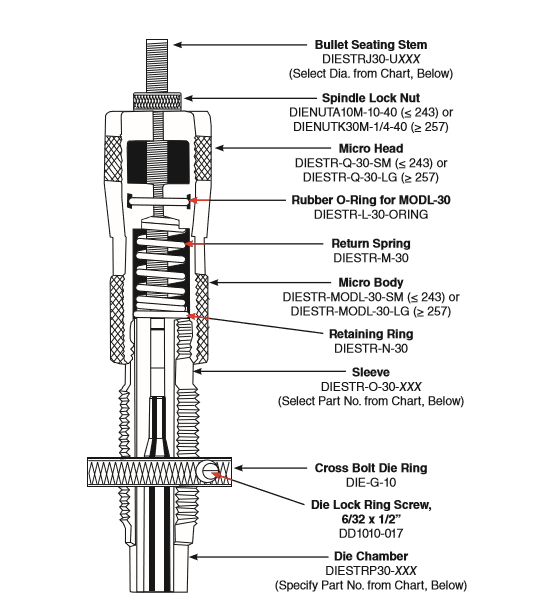

you must: firmly contact SLEEVE to your SHELLHODER.

if you have forster seating die with long DIE CHAMBER, than problem is bigger because DIE CHAMBER is blocking contact of SLEEVE and SHELLHOLDER. you should shorten this Die Chamber.

redding micrometer seating die is better, because there is shorter Die Chamber, and you can have Sleeve and Shellholder in full contact by default. but not in forster (mine didnt).

and forster Bullet Seating Stem is pathetic for modern VLD bullets...

you must: firmly contact SLEEVE to your SHELLHODER.

if you have forster seating die with long DIE CHAMBER, than problem is bigger because DIE CHAMBER is blocking contact of SLEEVE and SHELLHOLDER. you should shorten this Die Chamber.

redding micrometer seating die is better, because there is shorter Die Chamber, and you can have Sleeve and Shellholder in full contact by default. but not in forster (mine didnt).

and forster Bullet Seating Stem is pathetic for modern VLD bullets...

I have some WTC dies the very best you can buy and my B-O measurement with a 750 AMAX bullet varies, and so does my COAL, because of inconsistencies in the jacket of the bullet. BUt it shoots lights out, so I don't worry about it. If you measure from base of bullet to "ogive" on whatever device you're using, you may find that they're inconsistent.Measuring to the ogive with SMK bullets

Just throwing this out there...the last batch of 69gr SMK bullets I loaded had an OAL variance of .017. That is about twice of what I usually see. To make matters worse, the ogive ES was almost half that gross in only the 20 or so that I measured.

I was trying to run them to mag length for best accuracy in an AR. Now I'm seriously considering just using them as a plinking bullet.

I've spent my money on Berger and Lapua since. Still not perfect, but a heck of a lot better in regards to ogive and OAL consistency.

*****

My one and only Forester FL die set has the issue of the expander ball not opening the neck enough, and the excess tension caused quite the ring on my bullets (still shot really well). I just added another step with an expander mandrel set for .002 tension, and my ring problem virtually eliminated itself.

I was trying to run them to mag length for best accuracy in an AR. Now I'm seriously considering just using them as a plinking bullet.

I've spent my money on Berger and Lapua since. Still not perfect, but a heck of a lot better in regards to ogive and OAL consistency.

*****

My one and only Forester FL die set has the issue of the expander ball not opening the neck enough, and the excess tension caused quite the ring on my bullets (still shot really well). I just added another step with an expander mandrel set for .002 tension, and my ring problem virtually eliminated itself.

If overall seating effort is high you'll probably see higher variation in seating depth. Too much neck tension and/or super clean brass (no carbon left in the neck) seem to contribute to a sort of grab/stick/jump movement of the bullet in the neck rather than a smooth consistent slide. You can see it if you try to add just 1 or 2 thousandths to the seating depth. Nothing happens, nothing happens then BAM it jumps 5 or 10 thou. Technique with the press can make a bit of difference, are you pushing consistently to the same firm end point or are you pushing slowly so that it has a softer approach to where the press stroke ends that might be more variable.

Seating in virgin brass has always been less consistent for me than seating in fired/annealed/mandreled brass that only requires light to moderate pressure to seat a bullet.

If you want to hone the seating stem, chuck a bullet in a hand drill and slather it with metal polish then go to town on the seating stem. It won't remove a ton of metal but it will take off all the sharp edges that might catch.

Seating in virgin brass has always been less consistent for me than seating in fired/annealed/mandreled brass that only requires light to moderate pressure to seat a bullet.

If you want to hone the seating stem, chuck a bullet in a hand drill and slather it with metal polish then go to town on the seating stem. It won't remove a ton of metal but it will take off all the sharp edges that might catch.

Similar threads

- Replies

- 32

- Views

- 2K