Need a ego eye put on this, by someone who actually has some real armorer knowledge.

OK ( Me ) .. I know just enough for proper tear down and maintenance, and shooting/clean of the Glocks .

Last couple months I have been buying parts and assembling . I trying to acquire better understanding , learn a little more depth of mechanics, of GLOCK what I been carrying for many years AIWB pointed at my groin .

For someone who has put together a lot of Glocks. This probably sounds like sub-basic question, but I need an opinion of what I have here ?.

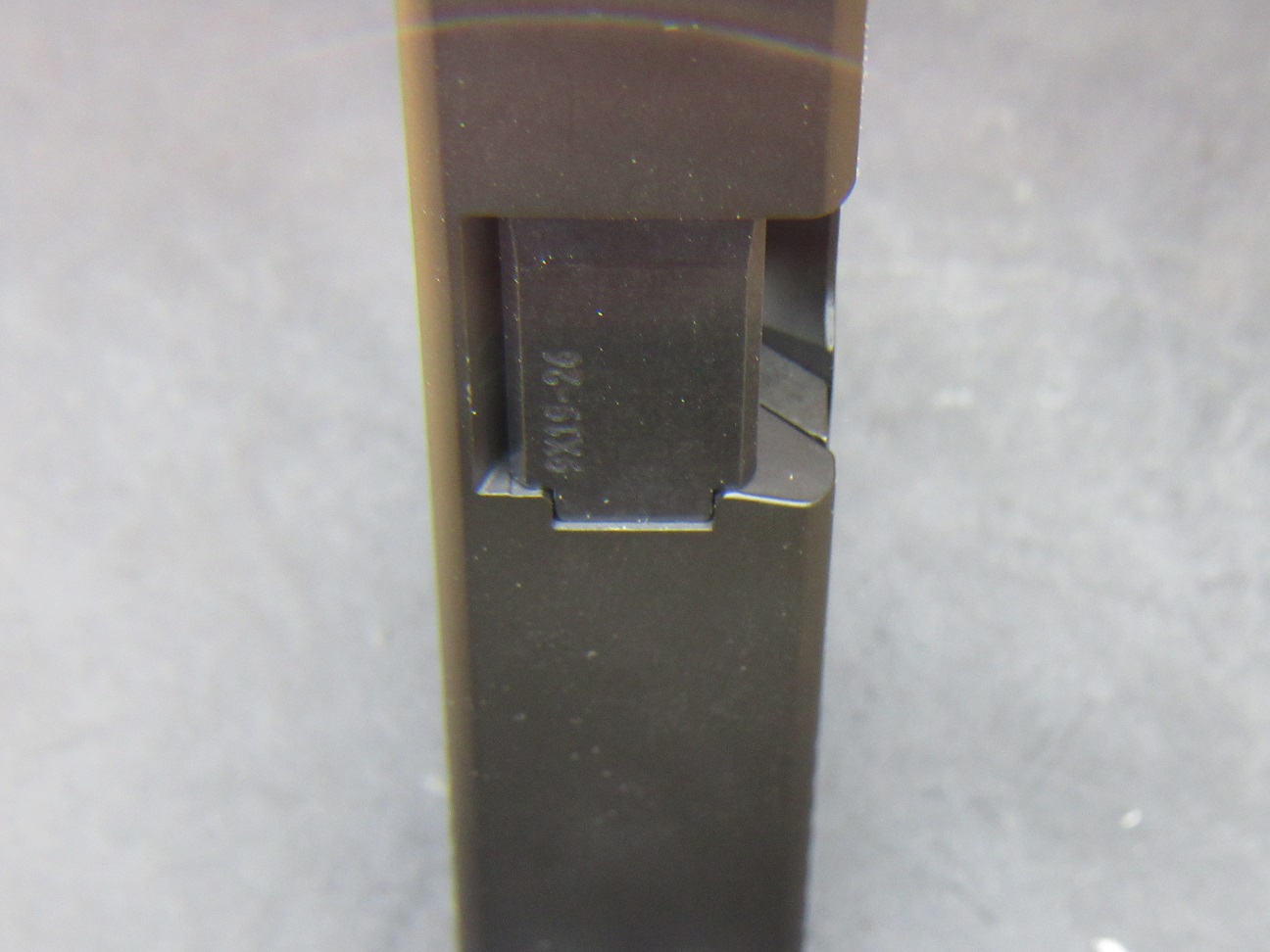

as far as the Hood not seating up higher and flush with the Slide ?

I have 26 and 19 that Barrels are flush fit with Hood and top of Slide . Is the distance shown in Pic. Safe ? , being that far down from Flush Fit ?

This Pic. . It is one of the aftermarket barrels that arrived together with Slides that I got last month .

-

-

OK ( Me ) .. I know just enough for proper tear down and maintenance, and shooting/clean of the Glocks .

Last couple months I have been buying parts and assembling . I trying to acquire better understanding , learn a little more depth of mechanics, of GLOCK what I been carrying for many years AIWB pointed at my groin .

For someone who has put together a lot of Glocks. This probably sounds like sub-basic question, but I need an opinion of what I have here ?.

as far as the Hood not seating up higher and flush with the Slide ?

I have 26 and 19 that Barrels are flush fit with Hood and top of Slide . Is the distance shown in Pic. Safe ? , being that far down from Flush Fit ?

This Pic. . It is one of the aftermarket barrels that arrived together with Slides that I got last month .

-

-

Last edited: