So I went out and did a little temperature testing this past Memorial Day. I was shooting a 24" Criterion 6XC with 105 RDFs .020" off the lands in 4x fired Norma brass. My H4350 load is 39.4 gr and my RL 16 load is 39.8 gr. The H4350 has a grain or so of wiggle room before any pressure signs, the RL16 loads are only a couple tenths off of heavy bolt lift. Both make nice little clusters though.

Anyways, I used a magneato speed v3 and little small infrared pocket thermometer for the temps, its not nasa quality but if can detect the relative difference in ice and fire.

I put 5 rounds of each powder in a ziploc and buried them in an ice chest before I went out. Then once out at the bench I left my ammo box in the shade and I put 5 rounds of both powders on the metal bumper in the sun to get them hot. Measured the temps were 35, 86 & 120.

With the MSv3 strapped on I ran a few sighters to warm up the barrel and put me on the 500 yard plate so I wasnt just putting them into the dirt. I shot slow and ran a chamber chiller between series to try and keep barrel heat out of the equation. It is starting to get hot enough here in TX that barrels get hot quick and stay there.

I started with the ambient temp rounds and actually shot 6 of each instead of 5 like the other temps just because I was sitting there and felt like it. Then I shot the cold rounds, then I shot the hot rounds so as to allow them to get as warm as they could get, took a couple hours all together.

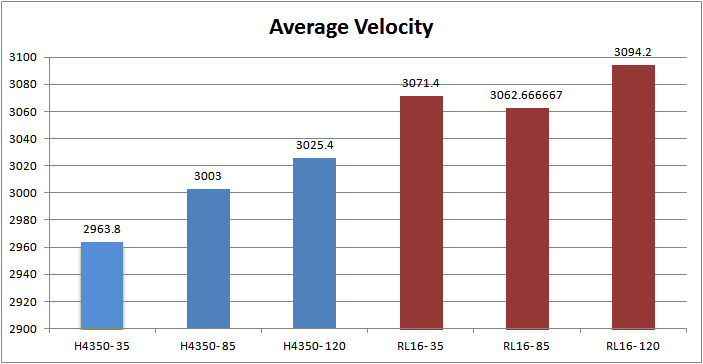

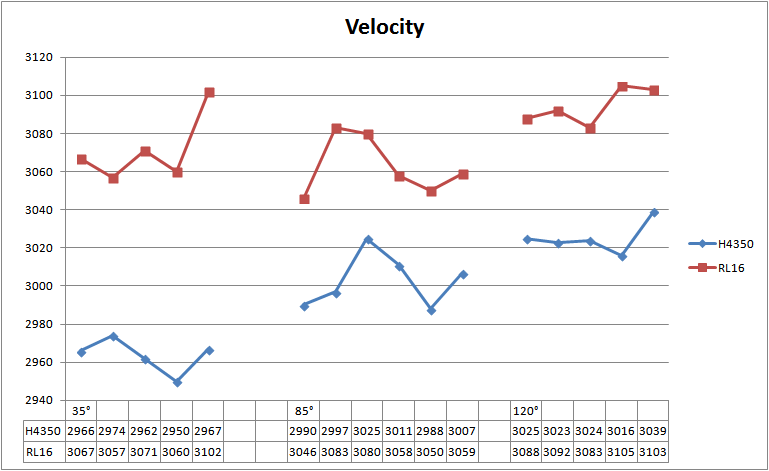

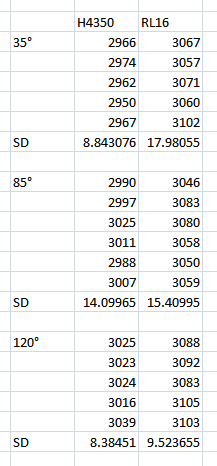

Anyways, heres the charts

Soooo it looks like the RL16 really is more temp stable, at least in my situation.

Anyways, I used a magneato speed v3 and little small infrared pocket thermometer for the temps, its not nasa quality but if can detect the relative difference in ice and fire.

I put 5 rounds of each powder in a ziploc and buried them in an ice chest before I went out. Then once out at the bench I left my ammo box in the shade and I put 5 rounds of both powders on the metal bumper in the sun to get them hot. Measured the temps were 35, 86 & 120.

With the MSv3 strapped on I ran a few sighters to warm up the barrel and put me on the 500 yard plate so I wasnt just putting them into the dirt. I shot slow and ran a chamber chiller between series to try and keep barrel heat out of the equation. It is starting to get hot enough here in TX that barrels get hot quick and stay there.

I started with the ambient temp rounds and actually shot 6 of each instead of 5 like the other temps just because I was sitting there and felt like it. Then I shot the cold rounds, then I shot the hot rounds so as to allow them to get as warm as they could get, took a couple hours all together.

Anyways, heres the charts

Soooo it looks like the RL16 really is more temp stable, at least in my situation.

Last edited: