Re: help fn action build

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: turbo54</div><div class="ubbcode-body">I think the main question this guy is asking is how much clearance between the bolt nose and the chamber.

Someone mentioned 10 thou. Whats the rationale there? I'd prefer 2 or 3 thou. </div></div>

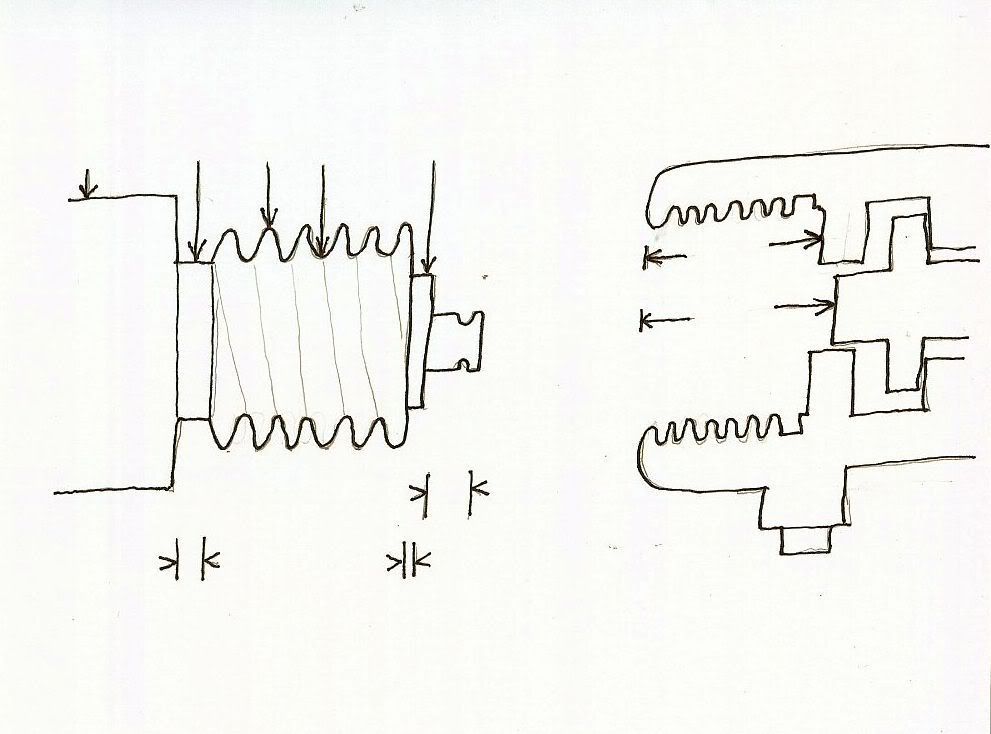

For the cone breech on a Winchester, I'd want more than .002 or .003" for clearance, in case of dirt or grit making it's way forward. Same for the extractor cut in the barrel. .010" might be a little much, but I usually do around .006-.007"

By the by, my notes from the FN SPR that I barreled about a year and a half ago say 96° total angle, or 48° from center.

Just my $.02