I have a prefit Barrel on my Tikka that I installed, I've been struggling with accuracy since I got it, Maybe me, maybe something else. My goals are to get out to long ranges with this rig, and my hope was to get into the ELR game a bit, but my shooting must improve before that happens.

I'm shooting some slow loads right now, and I'm right at about .9MOA at 300 yards, with ES~15ft/s, Hornady 147 ELD-Ms at 2550 ft/s.

130 ELD-Ms in Hornady brass do okay, but around the same accuracy at 2995ft/s.

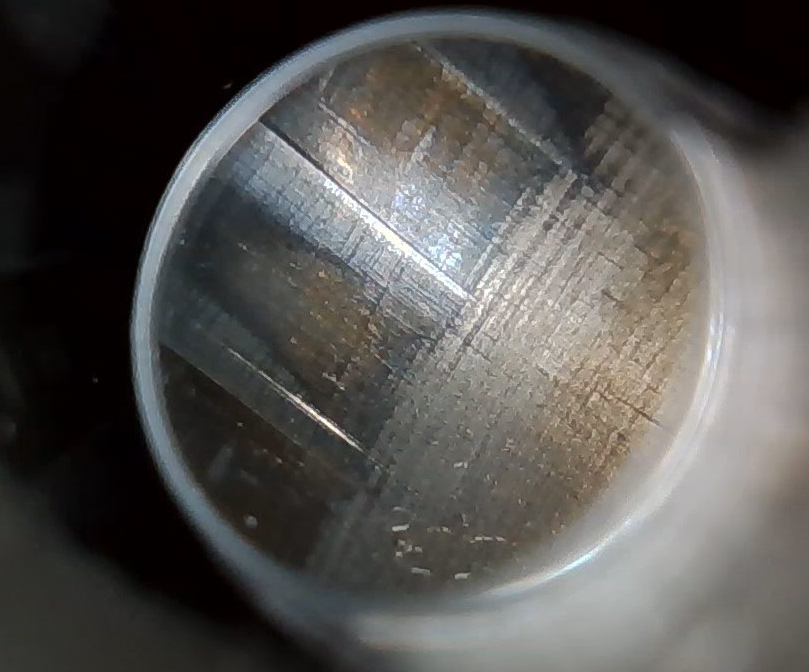

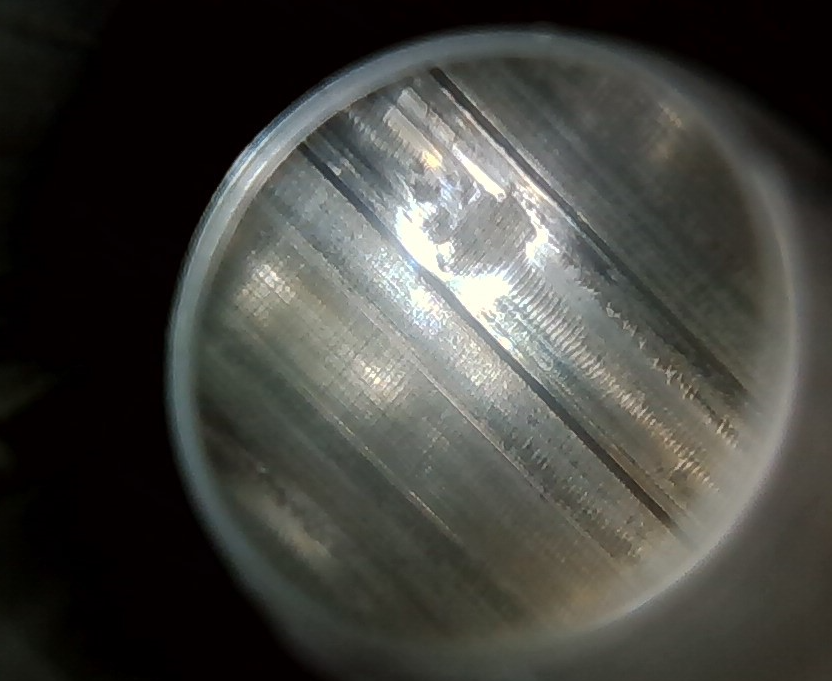

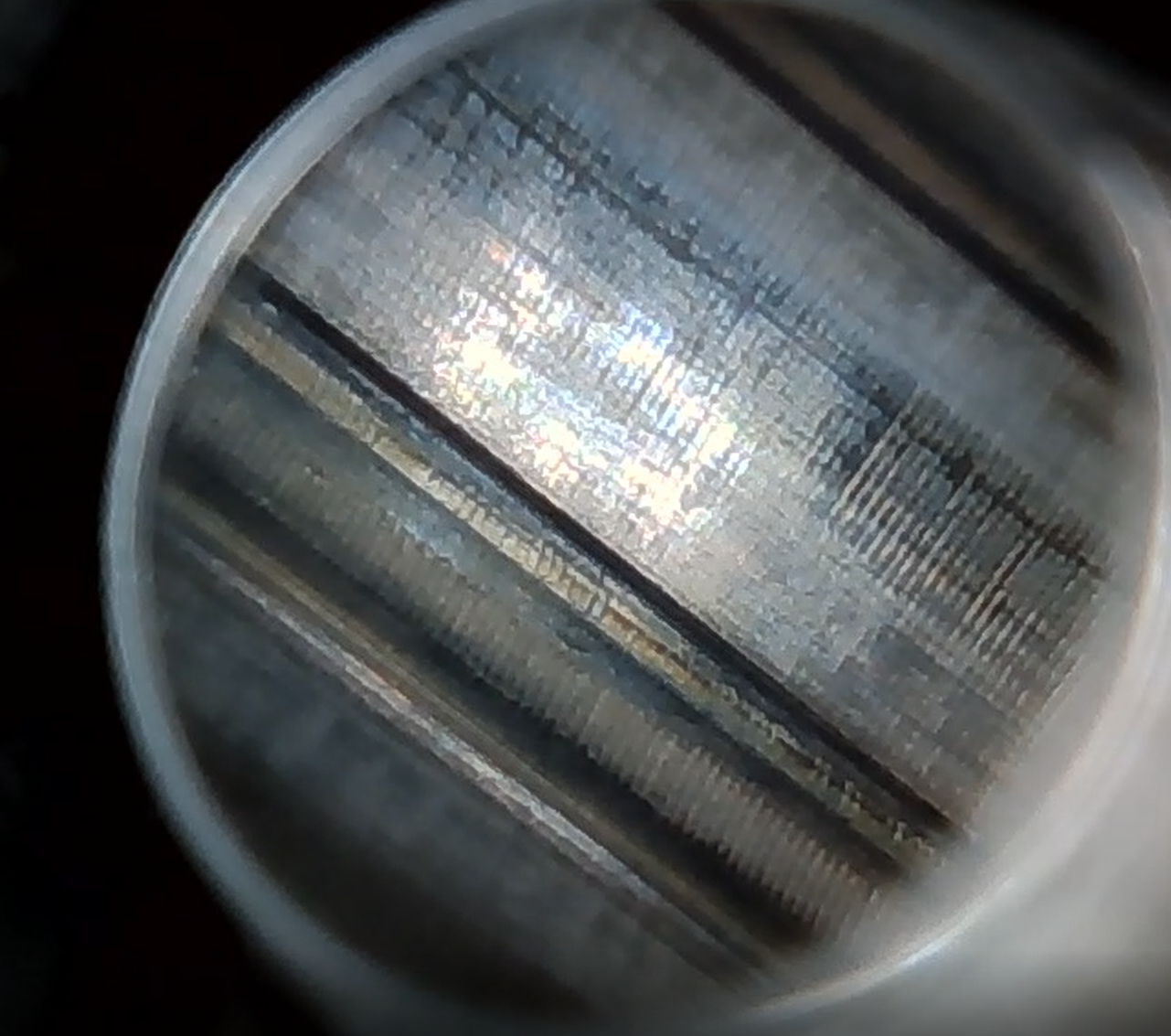

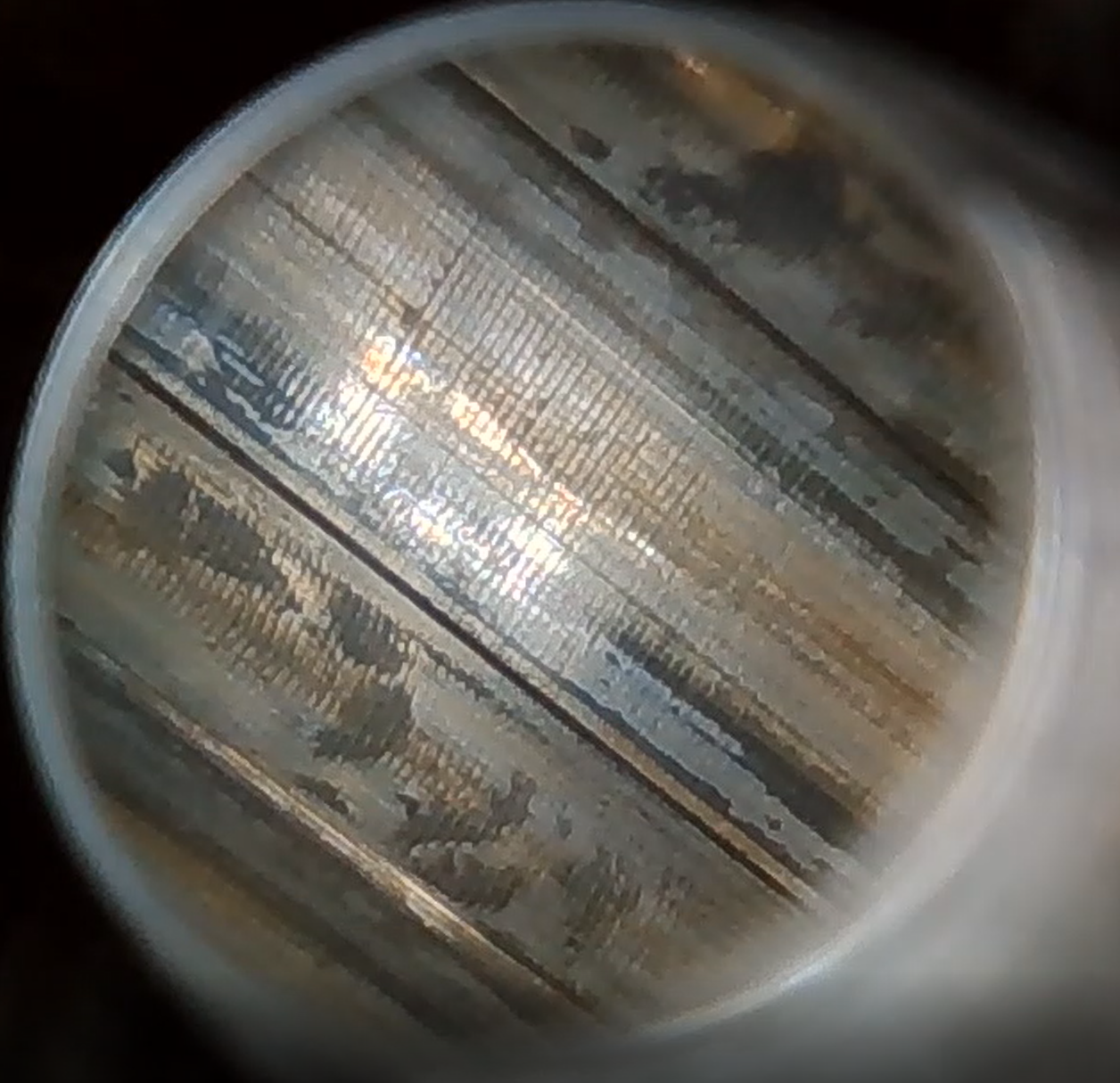

Anyway, after taking a step back and re-assembling everything, I figured a good barrel inspection was inorder, and this looks a tad rougher than what I was expecting. I'd love thoughts on other more experienced folks that can tell me this looks fine, or looks to be an issue. (I so wish I looked before I started shooting to better calibrate myself.) These photos are after alot of patches of CR-10 and Hopes. It still looks like a bit of Carbon and copper in here, so My thought is maybe CLR is an answer. It cleans my muzzle brake super well.

When inspecting this barrel, I keep noticing alot of copper fowling, even at 300 rounds down the tube.

The barrel is a 26in 6.5mm, 5R, 1:8.

Lands look okay, some fairly early fire cracking maybe?

This is a regular view, chatter marks, with what appears to be pockets.

There's a point 18 inches from the chamber in the barrel where its fowled with copper all the way around. almost like a very minor change in diameter at this point.

I'm curious for any thoughts. Thanks!

I'm shooting some slow loads right now, and I'm right at about .9MOA at 300 yards, with ES~15ft/s, Hornady 147 ELD-Ms at 2550 ft/s.

130 ELD-Ms in Hornady brass do okay, but around the same accuracy at 2995ft/s.

Anyway, after taking a step back and re-assembling everything, I figured a good barrel inspection was inorder, and this looks a tad rougher than what I was expecting. I'd love thoughts on other more experienced folks that can tell me this looks fine, or looks to be an issue. (I so wish I looked before I started shooting to better calibrate myself.) These photos are after alot of patches of CR-10 and Hopes. It still looks like a bit of Carbon and copper in here, so My thought is maybe CLR is an answer. It cleans my muzzle brake super well.

When inspecting this barrel, I keep noticing alot of copper fowling, even at 300 rounds down the tube.

The barrel is a 26in 6.5mm, 5R, 1:8.

Lands look okay, some fairly early fire cracking maybe?

This is a regular view, chatter marks, with what appears to be pockets.

There's a point 18 inches from the chamber in the barrel where its fowled with copper all the way around. almost like a very minor change in diameter at this point.

I'm curious for any thoughts. Thanks!