I just swapped out a factory 20 inch rifle gas psa 6.5 Creedmoor barrel for a 22 inch +2 gas barrel. This was the first firing on star line brass, had some strange rings around the base of the case on lighter loads, then some primers were leaking gas around them on a few pieces of the next few loads.

The hottest load I checked had a.010 bulge around the back of the case ( belted

magnum ) and one of those lost a primer and it jammed it's self in the bolt cam pin bore and locked the gun up.. needless to say I stopped there.

Shot some factory 123 grain federal stuff and brass looked fine, shot some of these same loads with the same brass out of the factory barrel and they looked fine. I did not run a set of headspace gages through this rifle after the barrel change. What are you guys thoughts? Thanks in advance.

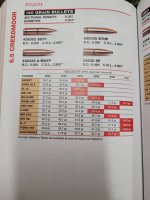

Loads were 39-43 grains of rl17 with 143 eldx set at 2.825 coal. Win primers

The hottest load I checked had a.010 bulge around the back of the case ( belted

magnum ) and one of those lost a primer and it jammed it's self in the bolt cam pin bore and locked the gun up.. needless to say I stopped there.

Shot some factory 123 grain federal stuff and brass looked fine, shot some of these same loads with the same brass out of the factory barrel and they looked fine. I did not run a set of headspace gages through this rifle after the barrel change. What are you guys thoughts? Thanks in advance.

Loads were 39-43 grains of rl17 with 143 eldx set at 2.825 coal. Win primers

Attachments

Last edited: