Electrician and resident pit comedians please help.

This is a water pump for an old lathe, high quality Chinese stuff from the 90s.

I gather it is 220 volts, 60 hertz?

I have single phase, three phase, as well as 480 three phase. I just need some help what this needs.

47.2 ohm between any two of the wires of the motor.

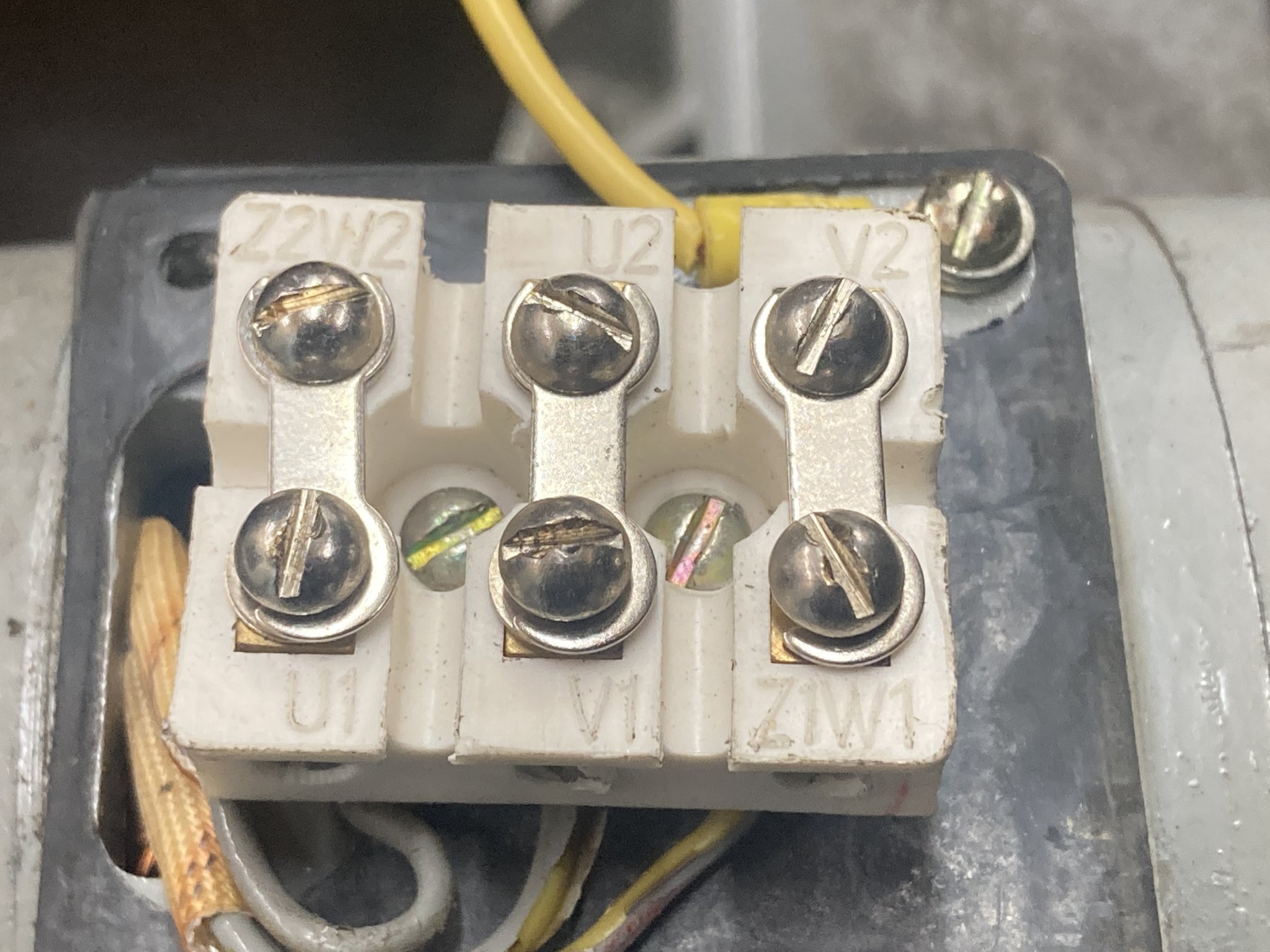

I have switched jumpers around before to change for different voltage, but there is always diagrams and tags in English.

I’ll post pics of the motor tag and the connection block inside the motor.

Can we make this work? Any more questions just ask.

Thanks!

This is a water pump for an old lathe, high quality Chinese stuff from the 90s.

I gather it is 220 volts, 60 hertz?

I have single phase, three phase, as well as 480 three phase. I just need some help what this needs.

47.2 ohm between any two of the wires of the motor.

I have switched jumpers around before to change for different voltage, but there is always diagrams and tags in English.

I’ll post pics of the motor tag and the connection block inside the motor.

Can we make this work? Any more questions just ask.

Thanks!

Last edited: