Took me some time to put this together and it is not 100% done yet...

I hope that this can help other members avoid some mistakes, get my take on some of the gear =)

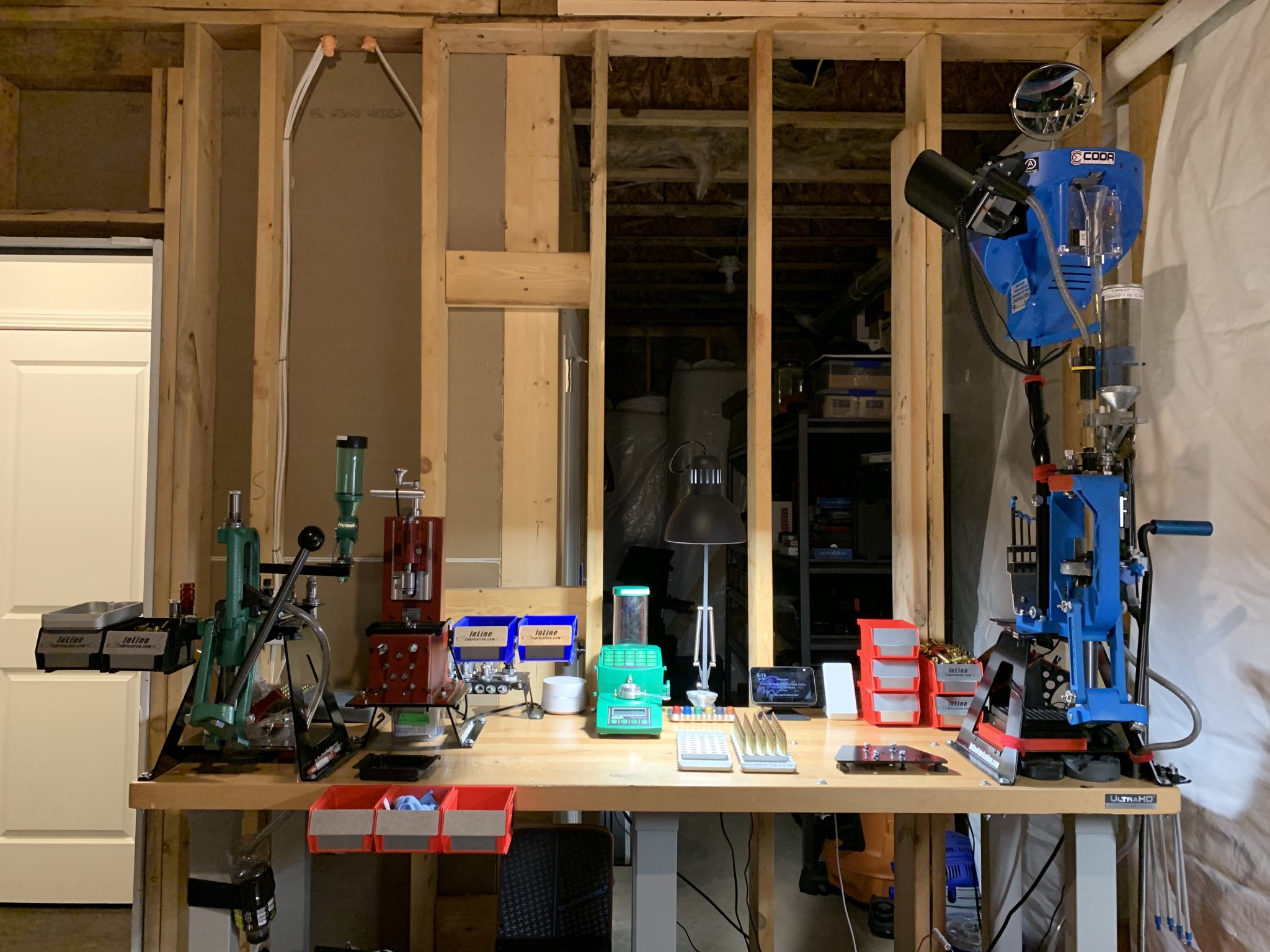

Here is an overview of how it is currently set up, we are missing the Forster Co-Ax that will sit right next to the Dillon 650.

This will only leave a little bit of room in the middle for Charging or some light bench duty.

The Workbench used is from Sam's club, the best 200 bucks I have ever spent! This thing is rock solid, solid butcher block and served me as a reloading table and work area.

Note that I have a LOT of stuff from InlineFabrication, I LOVE their stuff, it is priced right and works very very well.

I have tired to use the lower Ultramount for both the Dillon and RCBS... Don't, it's going to mess up your back. get the highest one and mount this as close to the edge of the workbench as possible. Also, ensure that the weight is on the bench is somewhat balanced, if not you will rock the table as you reload, ask me how I know.

To the right is where I have mounted the RCBS RockChucker, its a solid single stage pressed, I like it. I bought it initially to do my precision reloads, and I am sure it would have been fine but having seen a Forster Co-Ax, I opted to get that for the precision reload and I will use the RCBS for other operations.

Note that the RCBS has been outfitted with extra Bins and Dies holder, I have also mounted the PowerCharger on an arm swingy thingy very handy to move the PowderCharger in and out of the way.

I drilled a hole thru the table and fed the Spent Primer Catch tubing it goes into a Gatorade bottle that is strapped to one of the table's legs.

Right at the front of the Bench, you can see some Bins that are being held via a wall mount, very useful for dropping stuff like casing.

The 419 Ashtray is better served as a bullet holder =)

Right next to the RCBS is the Hornady Case Prep Center, I like this piece of gear but it feels a little outdated =)

Works great tho, and I would say that a mount is almost mandatory if you don't want to end up like that Disney character from Notre Dame. I added another arm swingy thingy to the mount, gives you extra bins when you handle cases and there is a secret feature that is not shown on the pic, that arm has a built-in shell holder, very cool!

Here is the backside, this is where I do the Priming, yes you can prime with the RCBS but the Lee Autoprimer feels pretty good and is very affordable.

Right behind the Hordany thingy is a die holder from Kinetic Arc Metalworks I love it very good quality and this thing is rock solid! It holds 15 Dies and some shell holders. Talking about shell holder, you can see that arms I was talking about from Inline Fab with the secret shell holder arm.

Moving along is where the RCBS ChargeMaster reside, this area will be the only "free" space where I can charge.

I really really like the 419 Reloading blocks, pricey but very cool. On the other hand, I don't like the Master Funnel thingy that much, for that kind of money I was expecting a little more, I had some concerns, told 419 about it, they sent me a replacement right away but my minor issues were still encountered with the new unit.

On the far left is where the Co-Ax will be set up, it's all ready to go, as soon as I find one in stock.

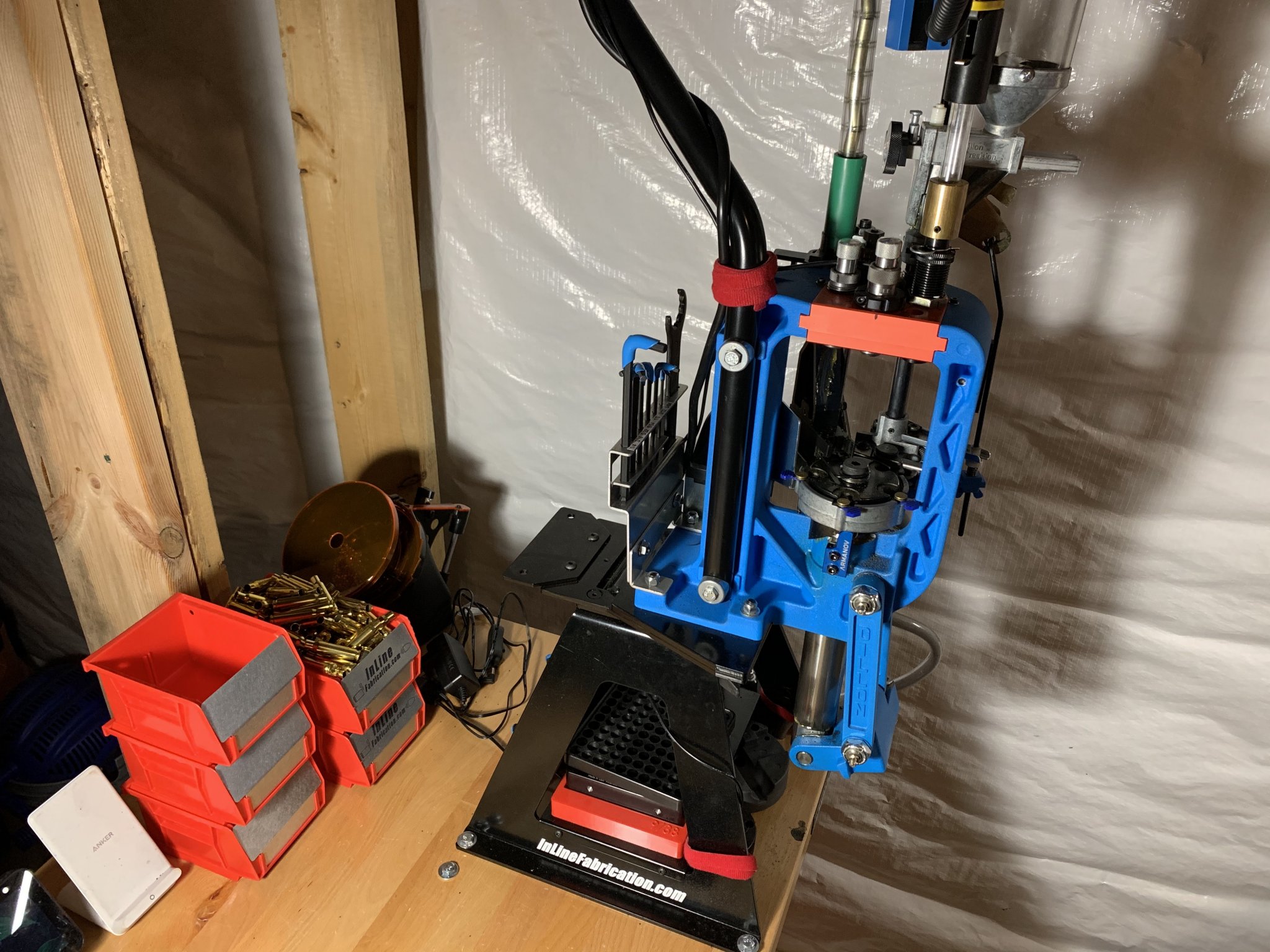

Here is the Dillon 650, fully decked out to crank out some 9 Major, the barebone 650 is pretty much not ready to go right out of the box.

Here are some mandatory upgrades IMHO:

- Upgraded Sheelplate Detent found on Ebay

- a Mount... Duh

- Dillon Case Feeder

- DAA Bullet Feeder... Wish I had that one much sooner, yeah its expensive but worth every pennies

- Inline Fab Ergo Handle

The Chute is from DAA, love it really speeds up the output.

What I don't like so much is that DAA Primer tube feeder thingy, that shit is so finicky...

Hope this helps!

I hope that this can help other members avoid some mistakes, get my take on some of the gear =)

Here is an overview of how it is currently set up, we are missing the Forster Co-Ax that will sit right next to the Dillon 650.

This will only leave a little bit of room in the middle for Charging or some light bench duty.

The Workbench used is from Sam's club, the best 200 bucks I have ever spent! This thing is rock solid, solid butcher block and served me as a reloading table and work area.

Note that I have a LOT of stuff from InlineFabrication, I LOVE their stuff, it is priced right and works very very well.

I have tired to use the lower Ultramount for both the Dillon and RCBS... Don't, it's going to mess up your back. get the highest one and mount this as close to the edge of the workbench as possible. Also, ensure that the weight is on the bench is somewhat balanced, if not you will rock the table as you reload, ask me how I know.

To the right is where I have mounted the RCBS RockChucker, its a solid single stage pressed, I like it. I bought it initially to do my precision reloads, and I am sure it would have been fine but having seen a Forster Co-Ax, I opted to get that for the precision reload and I will use the RCBS for other operations.

Note that the RCBS has been outfitted with extra Bins and Dies holder, I have also mounted the PowerCharger on an arm swingy thingy very handy to move the PowderCharger in and out of the way.

I drilled a hole thru the table and fed the Spent Primer Catch tubing it goes into a Gatorade bottle that is strapped to one of the table's legs.

Right at the front of the Bench, you can see some Bins that are being held via a wall mount, very useful for dropping stuff like casing.

The 419 Ashtray is better served as a bullet holder =)

Right next to the RCBS is the Hornady Case Prep Center, I like this piece of gear but it feels a little outdated =)

Works great tho, and I would say that a mount is almost mandatory if you don't want to end up like that Disney character from Notre Dame. I added another arm swingy thingy to the mount, gives you extra bins when you handle cases and there is a secret feature that is not shown on the pic, that arm has a built-in shell holder, very cool!

Here is the backside, this is where I do the Priming, yes you can prime with the RCBS but the Lee Autoprimer feels pretty good and is very affordable.

Right behind the Hordany thingy is a die holder from Kinetic Arc Metalworks I love it very good quality and this thing is rock solid! It holds 15 Dies and some shell holders. Talking about shell holder, you can see that arms I was talking about from Inline Fab with the secret shell holder arm.

Moving along is where the RCBS ChargeMaster reside, this area will be the only "free" space where I can charge.

I really really like the 419 Reloading blocks, pricey but very cool. On the other hand, I don't like the Master Funnel thingy that much, for that kind of money I was expecting a little more, I had some concerns, told 419 about it, they sent me a replacement right away but my minor issues were still encountered with the new unit.

On the far left is where the Co-Ax will be set up, it's all ready to go, as soon as I find one in stock.

Here is the Dillon 650, fully decked out to crank out some 9 Major, the barebone 650 is pretty much not ready to go right out of the box.

Here are some mandatory upgrades IMHO:

- Upgraded Sheelplate Detent found on Ebay

- a Mount... Duh

- Dillon Case Feeder

- DAA Bullet Feeder... Wish I had that one much sooner, yeah its expensive but worth every pennies

- Inline Fab Ergo Handle

The Chute is from DAA, love it really speeds up the output.

What I don't like so much is that DAA Primer tube feeder thingy, that shit is so finicky...

Hope this helps!