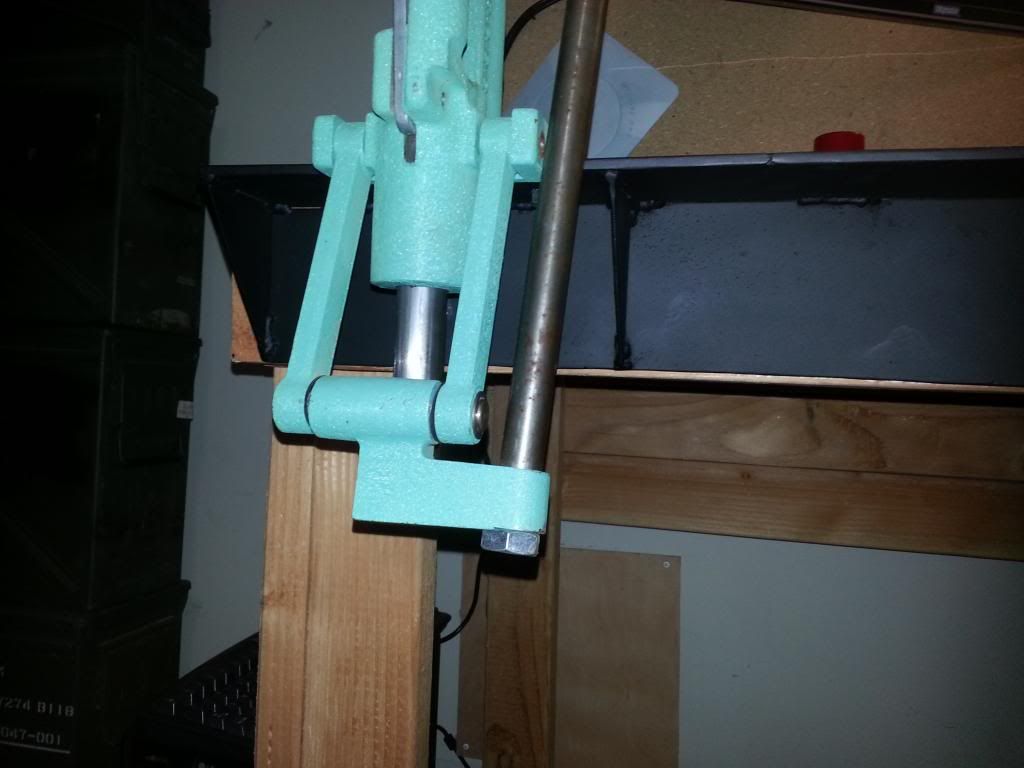

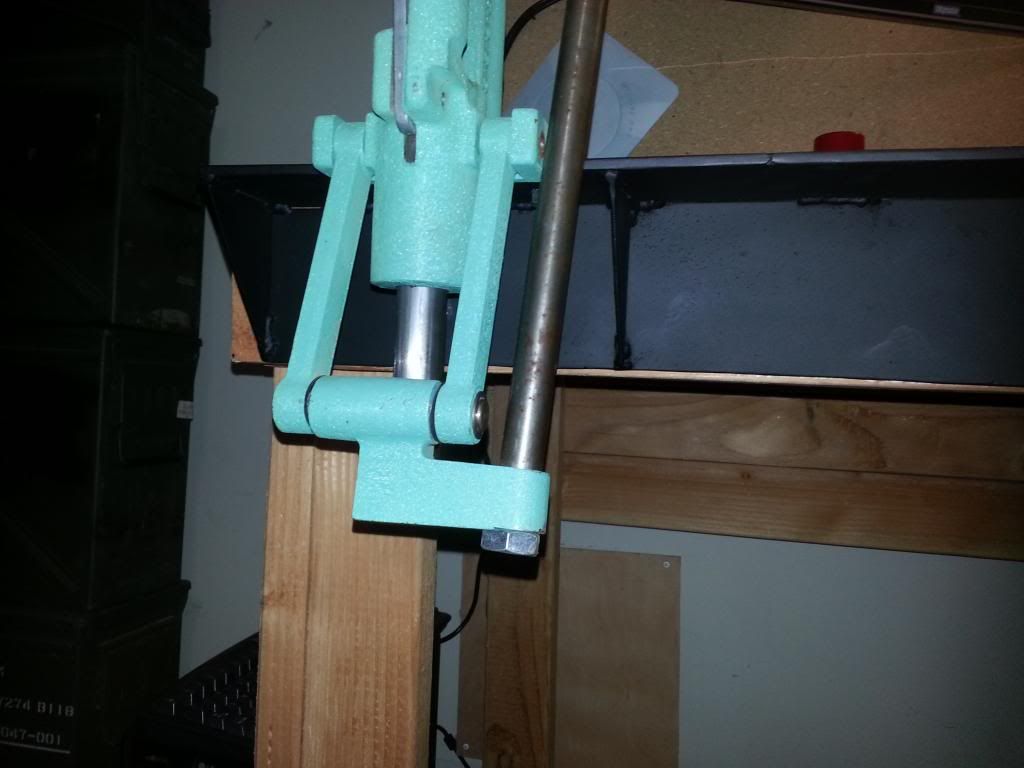

After trying to full length size some 308 with insufficient case lube, and hearing the wood on my bench crack, I decided that I wanted to reinforce the mounting for my presses. Not so I could continue to overwork the presses with not enough lube, but so that, in the future, any issues with reloading larger calibers would be automatically abated. I also had worked loose the bolts in my wooden tabletop (the wood is too soft), and found that, when mounted flush, my Rock Chucker wouldn't cam all the way because of the height of the lip of my bench. A friend who has been working with metal for most of his adult life lended his skills, tools, and some scrap mild 1/4" and 1/8" steel. After much cutting, grinding, sanding, welding, and with a little bit of Rustoleum, this is what we came up with.

The 1/4" top shelf bolts to the top of the bench in six places, three of which go through to a 1/8" steel plate underneath for extra support and distribution of energy. 1/8" 90 degree supports were welded to a second 1/8" plate that bolts to the front lip of the bench in two places. The presses then bolt directly onto the 1/4" plate. I now have full travel of my Rock Chucker without the clown-like look that would have come had I just dremmeled away some of the 2x4 front lip material to make clearance. I stood on the 4" deep press mounting lip after I secured the shelf to the bench, and jumped up and down a bit. Thing is as solid as a rock now.

The 1/4" top shelf bolts to the top of the bench in six places, three of which go through to a 1/8" steel plate underneath for extra support and distribution of energy. 1/8" 90 degree supports were welded to a second 1/8" plate that bolts to the front lip of the bench in two places. The presses then bolt directly onto the 1/4" plate. I now have full travel of my Rock Chucker without the clown-like look that would have come had I just dremmeled away some of the 2x4 front lip material to make clearance. I stood on the 4" deep press mounting lip after I secured the shelf to the bench, and jumped up and down a bit. Thing is as solid as a rock now.