Gunsmithing How do you clamp when bedding?

- Thread starter tucansam

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Zip ties, Big ones. You aren't looking to "clamp". Just hold the action in the same place. Theory has it when you clamp the action it introduces stress into the stock and action causing them to flex.

I use headless bolts screwed down into the action with a bit of tape wrapped around the bolt for a tight fit in the pillars. The action is upside down when the stock is placed down over the screws. Making sure the stock is bottomed out I wrap the stock and action with masking tape.

I wonder if thats what C.Dixon does, I would imagine he has something space age but you never know.

There is no clamping, only supporting with no induced pressure or twist.

Studs in the action screws extending thru the pillars and the barrel wrapped with painters tape (2 places) to level the action to sit flat.

This right here.

I wonder if thats what C.Dixon does, I would imagine he has something space age but you never know.

Chad uses zip ties from the hobby store. That's it...nothing fancy

Chad uses zip ties from the hobby store. That's it...nothing fancy

I've never seen a better looking bedding job than some I've seen in his pics and videos.

I've never seen a better looking bedding job than some I've seen in his pics and videos.

I'm not familiar with his work. any links?

Here is one video that shows it. I do notice a zip tie or two but they come in after a large clamping device.

[video]http://m.youtube.com/watch?v=yC3soqc66ds&desktop_uri=%2Fwatch%3Fv%3DyC3soqc66ds[/video]

[video]http://m.youtube.com/watch?v=yC3soqc66ds&desktop_uri=%2Fwatch%3Fv%3DyC3soqc66ds[/video]

I use headless bolts screwed down into the action with a bit of tape wrapped around the bolt for a tight fit in the pillars. The action is upside down when the stock is placed down over the screws. Making sure the stock is bottomed out I wrap the stock and action with masking tape.

I do this but with zip ties instead of masking tape.

Yes, call them.

Anyone know if they will bed an existing action into a customers stock? and an approximate price?

Yes they will. About $750 not counting paint.

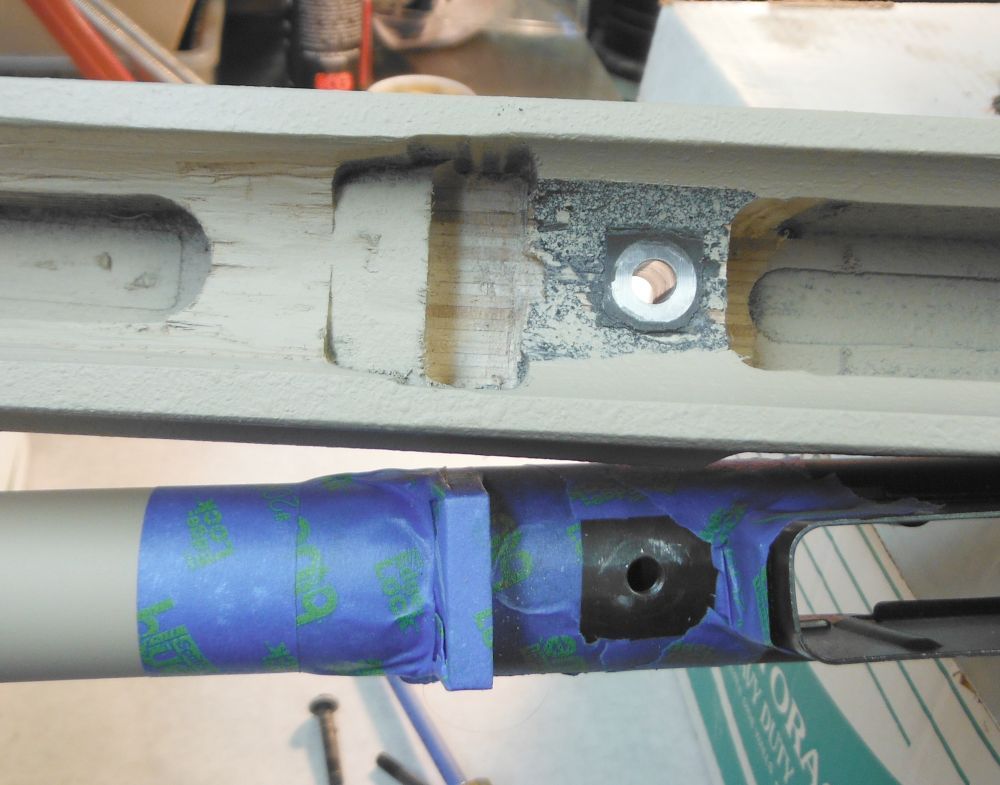

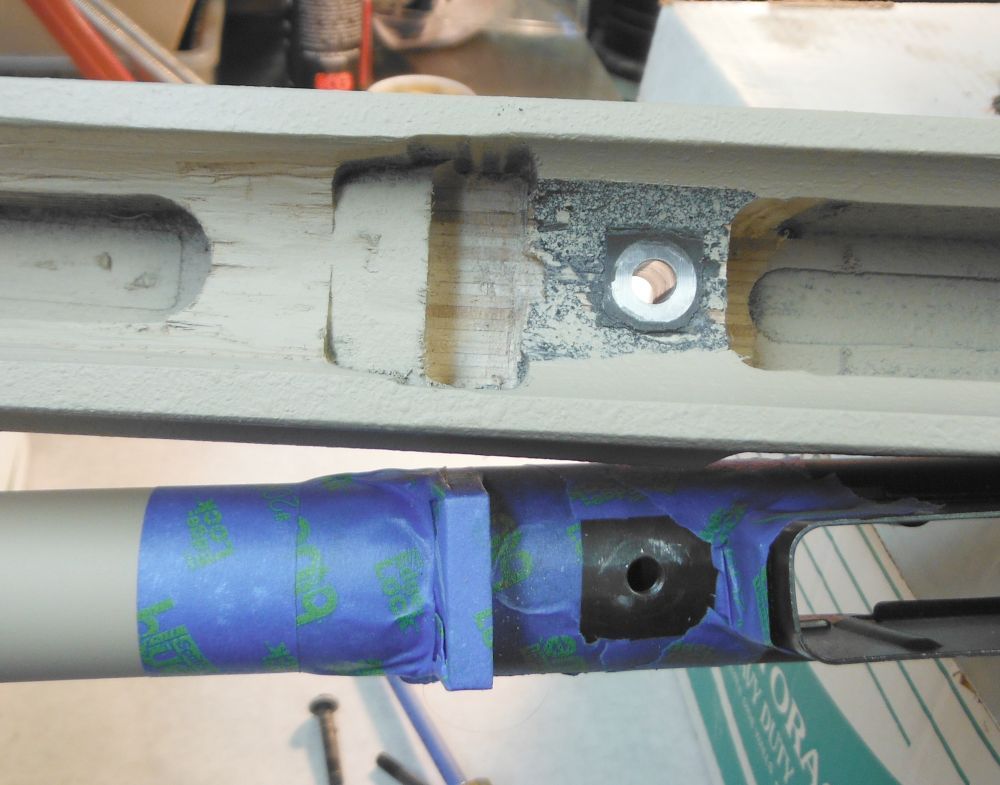

Over the last two weeks I bedded one, and this is how I did it.

I cut pillars on the lathe from 1/2" aluminum alloy round stock and then mill the ends with a boring head to get a radius that matches the round receiver.

I put the barrelled action upside down in the barrel vise and level it.

I put the pillars on and pre compress them with the action screws.

I set the space between the barrel and stock and between the action and stock with layers of tape.

I put Devcon on the pillars.

I put the stock over the pillared action and wrap surgical cord around them to bind them together.

I level the stock.

After the pillars have cured, I measure the volume of the recoil lug well and the volume of the recoil lug. I calculate how full to fill the recoil lug well with Devcon.

I get the rifle right side up, up in the air, with the recoil lug well filled with the right amount of Devcon, and then I tighten the the action screws.

When done the barreled action only touches the stock at the two pillars and the back of the recoil lug.

The action screws should be such a low compliance connection that they go from first resistance to maximum torque in 10 degrees of rotation.

The barrel should sound like a tuning fork when smacked with an open hand when the rifle is supported at the wrist.

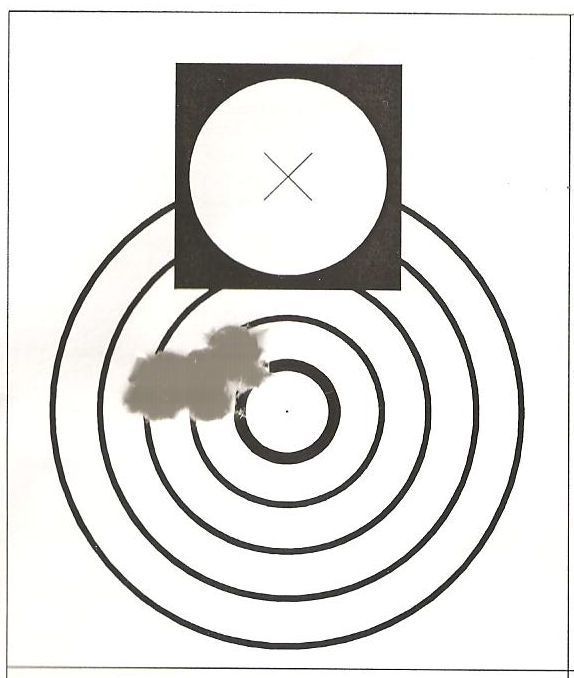

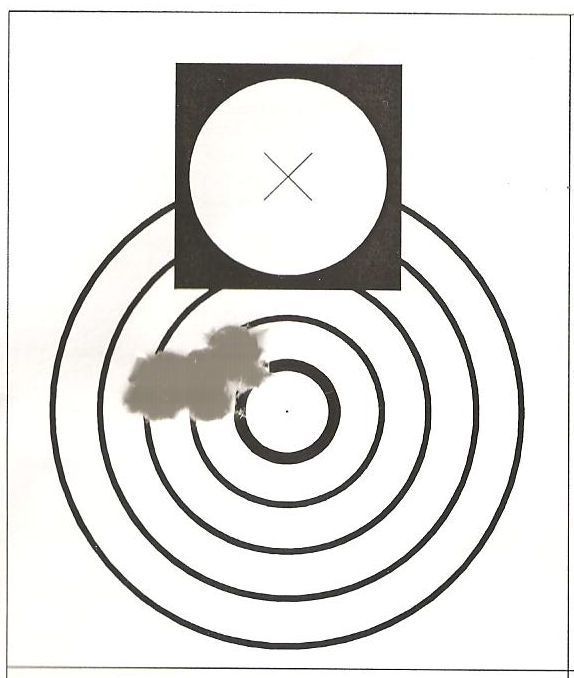

A $109 Boyd's tacticool stock, a $114 Lothar Walther 223 barrel blank, and a $240 Sav action made in 1988 shoots it's first 5 shot group at 100 yards.

I cut pillars on the lathe from 1/2" aluminum alloy round stock and then mill the ends with a boring head to get a radius that matches the round receiver.

I put the barrelled action upside down in the barrel vise and level it.

I put the pillars on and pre compress them with the action screws.

I set the space between the barrel and stock and between the action and stock with layers of tape.

I put Devcon on the pillars.

I put the stock over the pillared action and wrap surgical cord around them to bind them together.

I level the stock.

After the pillars have cured, I measure the volume of the recoil lug well and the volume of the recoil lug. I calculate how full to fill the recoil lug well with Devcon.

I get the rifle right side up, up in the air, with the recoil lug well filled with the right amount of Devcon, and then I tighten the the action screws.

When done the barreled action only touches the stock at the two pillars and the back of the recoil lug.

The action screws should be such a low compliance connection that they go from first resistance to maximum torque in 10 degrees of rotation.

The barrel should sound like a tuning fork when smacked with an open hand when the rifle is supported at the wrist.

A $109 Boyd's tacticool stock, a $114 Lothar Walther 223 barrel blank, and a $240 Sav action made in 1988 shoots it's first 5 shot group at 100 yards.

If your bedding without pillars, no tape is needed. It should have two contact points, one is tape around the barrel near at the end of the barrel channel and the other is on the stock just behind the rear screw hole. If pillar and skim bedding at the same time you need zip ties or tape to hold it in place but still use the same two points of contact.

How do you clamp when bedding?

The theory of recessed bedding is to fully encapsulate the action in bedding material. This reduces the potential for breakage of bedding material where it gets thin at the top of the pillar. This can lead to unexplained fliers. The contoured pillars solve the problem of the thin compound at the top of the pillar, but, it won't fully encapsulate the action. There is a pillar made by Longrifles Inc. that gives the best of both worlds. It's sold by Grizzly Industrial. http://grizzly.com/products/T10444. It's probably overkill though. Epoxy can get brittle. Especially when applying 65in/lb loads to a small area. Now, think about recessed bedding. There is no support other than the epoxy. Place repeated loads on the bedding and it's going to crack sooner or later.

The theory of recessed bedding is to fully encapsulate the action in bedding material. This reduces the potential for breakage of bedding material where it gets thin at the top of the pillar. This can lead to unexplained fliers. The contoured pillars solve the problem of the thin compound at the top of the pillar, but, it won't fully encapsulate the action. There is a pillar made by Longrifles Inc. that gives the best of both worlds. It's sold by Grizzly Industrial. http://grizzly.com/products/T10444. It's probably overkill though. Epoxy can get brittle. Especially when applying 65in/lb loads to a small area. Now, think about recessed bedding. There is no support other than the epoxy. Place repeated loads on the bedding and it's going to crack sooner or later.

Last edited:

When I did my stock, I simply used a pair of large Harbor Freight carpenter's clamps with light clamping force to hold the action into place.

12" Ratcheting Bar Clamp / Spreader

12" Ratcheting Bar Clamp / Spreader

Similar threads

- Replies

- 0

- Views

- 417

Advanced Marksmanship Where on the rifle do you measure scope height?

- Replies

- 4

- Views

- 239