Hello. Could you explain for beginners because 2 variables are important: seating depth and load. I just started learning how to reload: what should I do: use the ~20 seating depth option ( if move with 0.003" increment) on each possible load from the range of possible loads (139 scenars on 6.5 credmoor - 34-39.7 gr, as suggested by VihtaVouri in their docs. I have access only for Vihta powders)? To find the right fit?.. Even in 0.5 grain increments, that's 34, 34.5, 35...39.5, that's 10 charges * 20 landings * 3 bullets each == 600 total.. If I don't know the seating depth and load for my new rifle? How to find the right one?

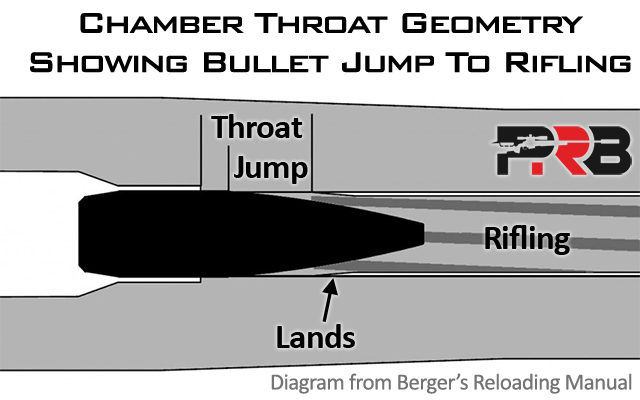

Normal COAL for a 6.5 CM is 2.800" and with that COAL, the amount of bearing surface in the neck is .274". I think you'll find that this .274" puts the start of the bearing surface right at the neck-shoulder junction. It's a good idea to not have the bearing surface touching the neck-shoulder junction. So, to start with you'll want to start to go a little longer COAL than the 2.800" and give yourself plenty room to make those seating depth adjustments. Let's say, you're going to do 10 increments (which is more than enough to find a node) of .003" for a total range of .030" Add that to the 2.800 + a little extra to be sure to keep away from the neck-shoulder junction, make the starting COAL 2.840. You could start longer, but you being a beginner, I wouldn't recommend that. This will leave .234" of bearing surface in the neck to start with and that will increase as you adjust you're seating depth down. That .234" in contact with the cartridges neck is plenty to hold well.

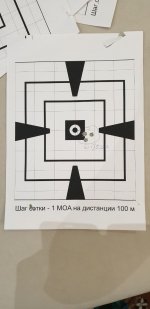

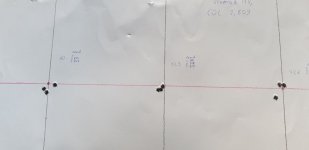

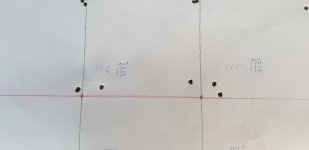

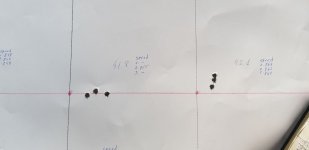

Next, start with a powder load no closer than within 90% of the listed max. Load 3 cartridges for each powder load in .3 grs increments. If you use 10 increments, 3 cartridges each, that's 30 you'll be firing. You should find something that looks good within that spread of 10. Select the load that produces the least vertical (not so much a tight group, because you can have a rather small group where all three shots are stacked vertical and that's not what you want). Select the group with a little variation in vertical, even though they may not be touching. You may even see three groups with horizontal pretty much in the same plane; if so, choose the one in the middle or interpolate a powder load that might look the best of them. Once you decide on which powder load looks good, you can move on to seating depth test.

For seating depth test to improve on what you've done so far, you'll be doing 10 increments again of .003" adjustments and using 3 shots for each increment; that equals just 30 bullets. You've evaluation will be much like you did for the powder charge test, only the size of the groups should all be less.

This process I've described so far, you're only firing 60 cartridges. Once you've done your seating test and found a good one, you'll then need to verify it to be sure. If you can't repeat the good groups, then you're got to reevaluate what you see on your test targets. If the good groups are repeating, then you're good to go and you've used less than 100 rounds.

BTW, if you haven't already shot 100-150 rounds through you're new gun, it may be to soon to do such testing as it take a good 100+ rounds to stabilize your barrel. Velocity will typically increase after 100+ rounds, which will make a difference in your load development. Usually, with a new gun or barrel, one can use this time to fireform your cases as that's one of the things that should be done before you get into precision reloading. If precision reloading is not your aim, then . . . never mind.