I got in on the McGowen labor day sale and ordered up a howage in 22 creedmoor. I finally tried to go and install it and Im running into something that I have never encountered in my limited experience, and it may be just fine, but I want to ask the smiths first.

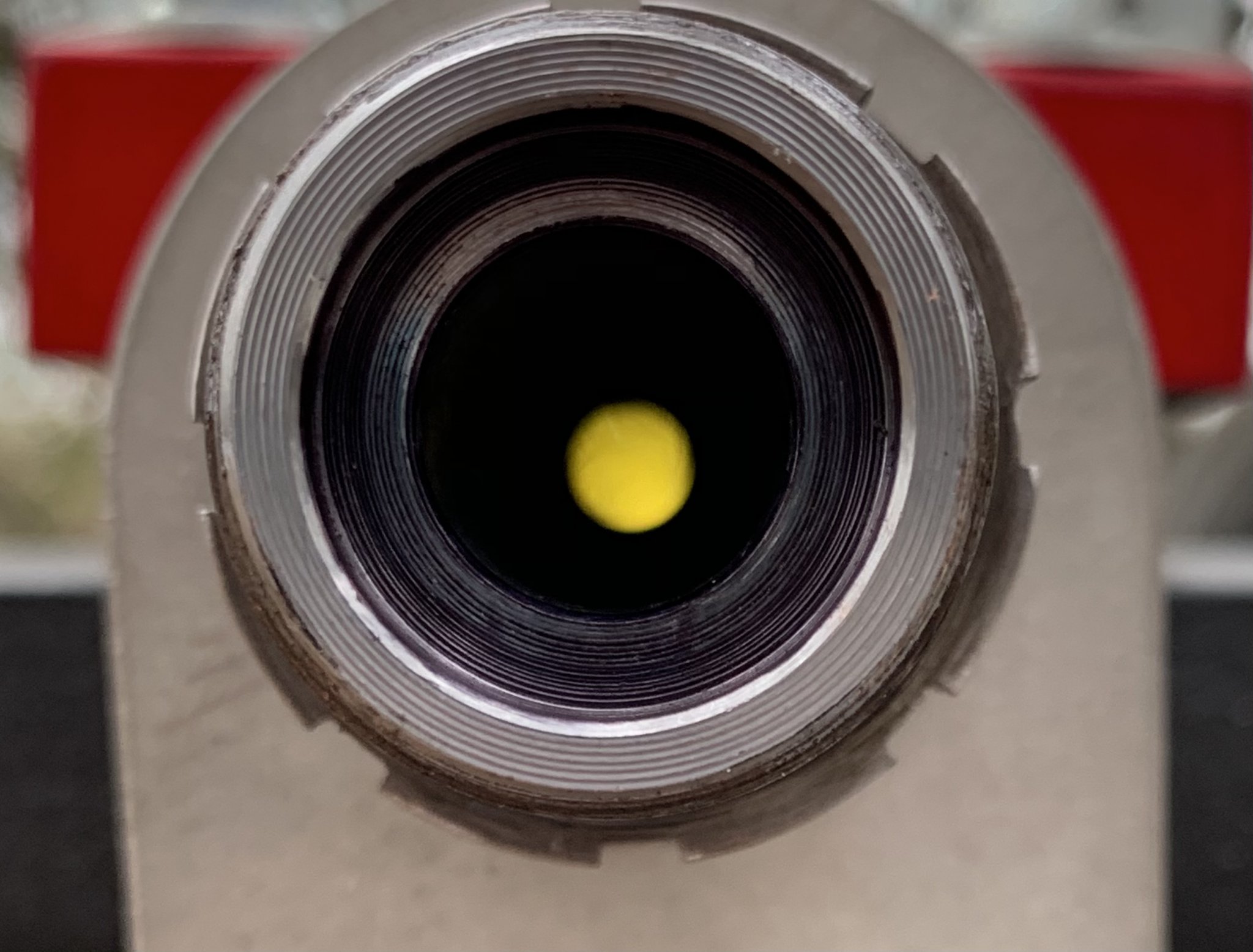

I put the go gauge under the extractor and threaded the barrel in until it stopped on the go gauge... only it didnt stop on the go gauge, it bottomed out on the bolt nose. I have colored the bolt nose in sharpie as well as the barrel counter bore and you can see where its rubbing.

Blacked

Rubbed

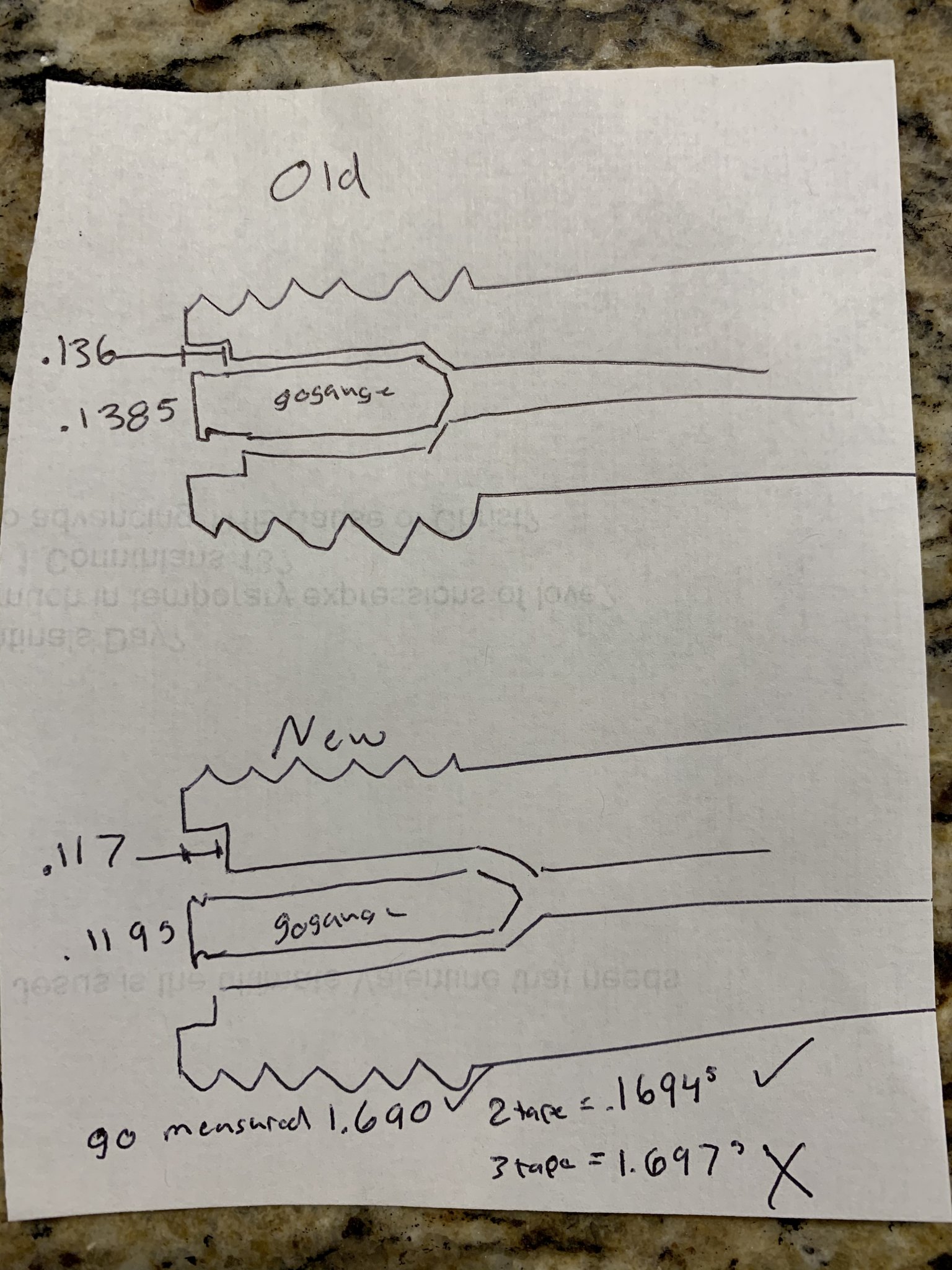

In measuring the counter bores from the factory barrel to the new barrel and I have ~.020 of difference. The old barrel measured .136" of counter bore depth and the new barrel measures .117 of counter depth. With the go gauge in and measuring its protrusion from that counter bore depth in the old barrel I had .1385 and in the new barrel I have .1195

So that tells me why I was bottoming out. The relative difference in go gauge protrusion was equal between the two, its just where their absolute position is in regard to the bolt face thats the issue I think.

Next I wanted to know how much short the go gauge was I screwed the barrel in until it just touched the bolt nose and moved it out ever so slightly and tightened it down. With the barrel in that spot the bare go gauge measures 1.690 oal, with 2 pieces of tape at 1.6945 and the bolt still closes. 3 pieces of scotch tape measures 1.6975 and thats where the bolt finally bottoms out on the gauge and the handle can no longer fall.

Do we think that .007 over the go is bad? That would fall right in between the nogo and the field gauge (if I had them). Since this is a wild cat of sorts (well, at least nonsaami) I will be reloading only so I suppose is do we think that extra growth will have a negative impact or will be it just fine after its initial firing stretch.

I put the go gauge under the extractor and threaded the barrel in until it stopped on the go gauge... only it didnt stop on the go gauge, it bottomed out on the bolt nose. I have colored the bolt nose in sharpie as well as the barrel counter bore and you can see where its rubbing.

Blacked

Rubbed

In measuring the counter bores from the factory barrel to the new barrel and I have ~.020 of difference. The old barrel measured .136" of counter bore depth and the new barrel measures .117 of counter depth. With the go gauge in and measuring its protrusion from that counter bore depth in the old barrel I had .1385 and in the new barrel I have .1195

So that tells me why I was bottoming out. The relative difference in go gauge protrusion was equal between the two, its just where their absolute position is in regard to the bolt face thats the issue I think.

Next I wanted to know how much short the go gauge was I screwed the barrel in until it just touched the bolt nose and moved it out ever so slightly and tightened it down. With the barrel in that spot the bare go gauge measures 1.690 oal, with 2 pieces of tape at 1.6945 and the bolt still closes. 3 pieces of scotch tape measures 1.6975 and thats where the bolt finally bottoms out on the gauge and the handle can no longer fall.

Do we think that .007 over the go is bad? That would fall right in between the nogo and the field gauge (if I had them). Since this is a wild cat of sorts (well, at least nonsaami) I will be reloading only so I suppose is do we think that extra growth will have a negative impact or will be it just fine after its initial firing stretch.

Last edited: