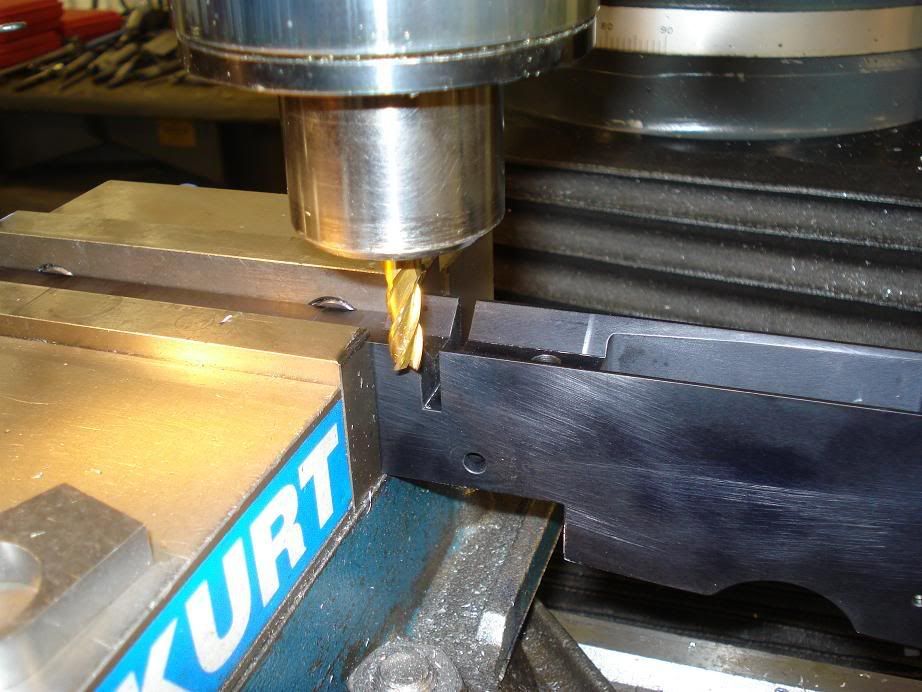

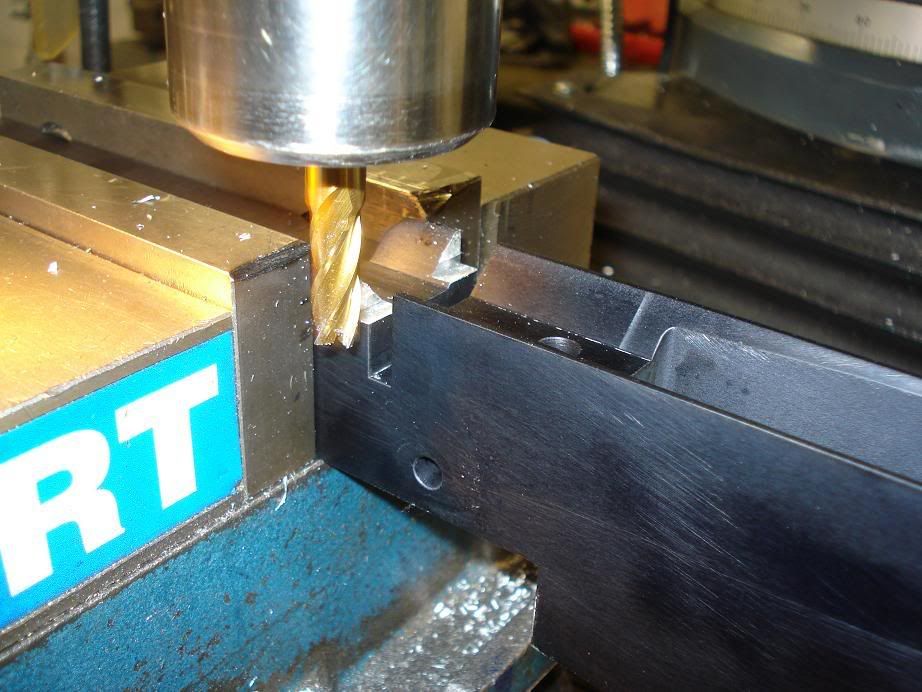

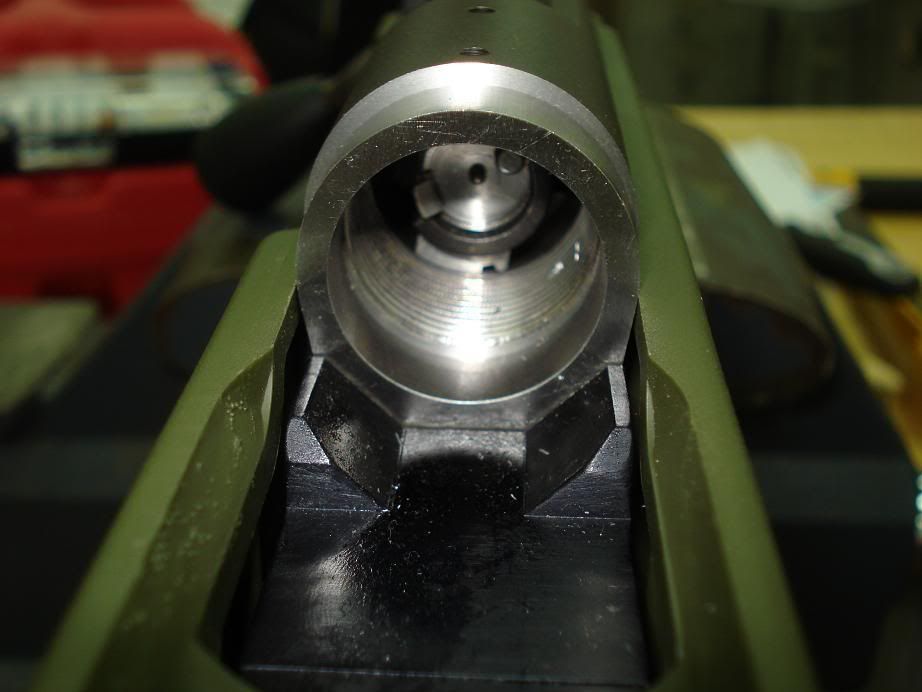

Re: Inletting AICS lug area for .3 tubb lug

Yeah that is a good setup that you had. Those pictures were taken at Montgomery Community College in Troy, NC. They have a great set up plenty of new machines that work great......I was spoiled!!! All of them had DRO's, lathes had a matching 4 jaw, 3 jaw, collet chuch, a whole collet set. Coolent systems, accurate tailstocks and just about all the support equipment and tools needed to do correct gunsmithing. It is going to be pretty expensive to duplicate the setup for myself one day.