Some of you may remember a few years ago I drew a concept for an "AIAC" competition chassis for the current AI rifle platform. Nothing ever really came from that outside of some good conversation between fellow AI fans and competition rifle shooters. That concept has been a bug in my brain since then, and a few months ago I decided to make it a reality, taking into account current design trends and the overall design language of AI rifles in general.

Shown here is the final plastic 3D printed prototype of my 100% self-designed Obsession Chassis. The next real step is to complete the drawings and get one of these machined for testing. I'm not entirely sure where I will get one machined, and I know one-offs are very expensive, but I need to test an aluminum version before I would ever consider making more and offering them to other shooters.

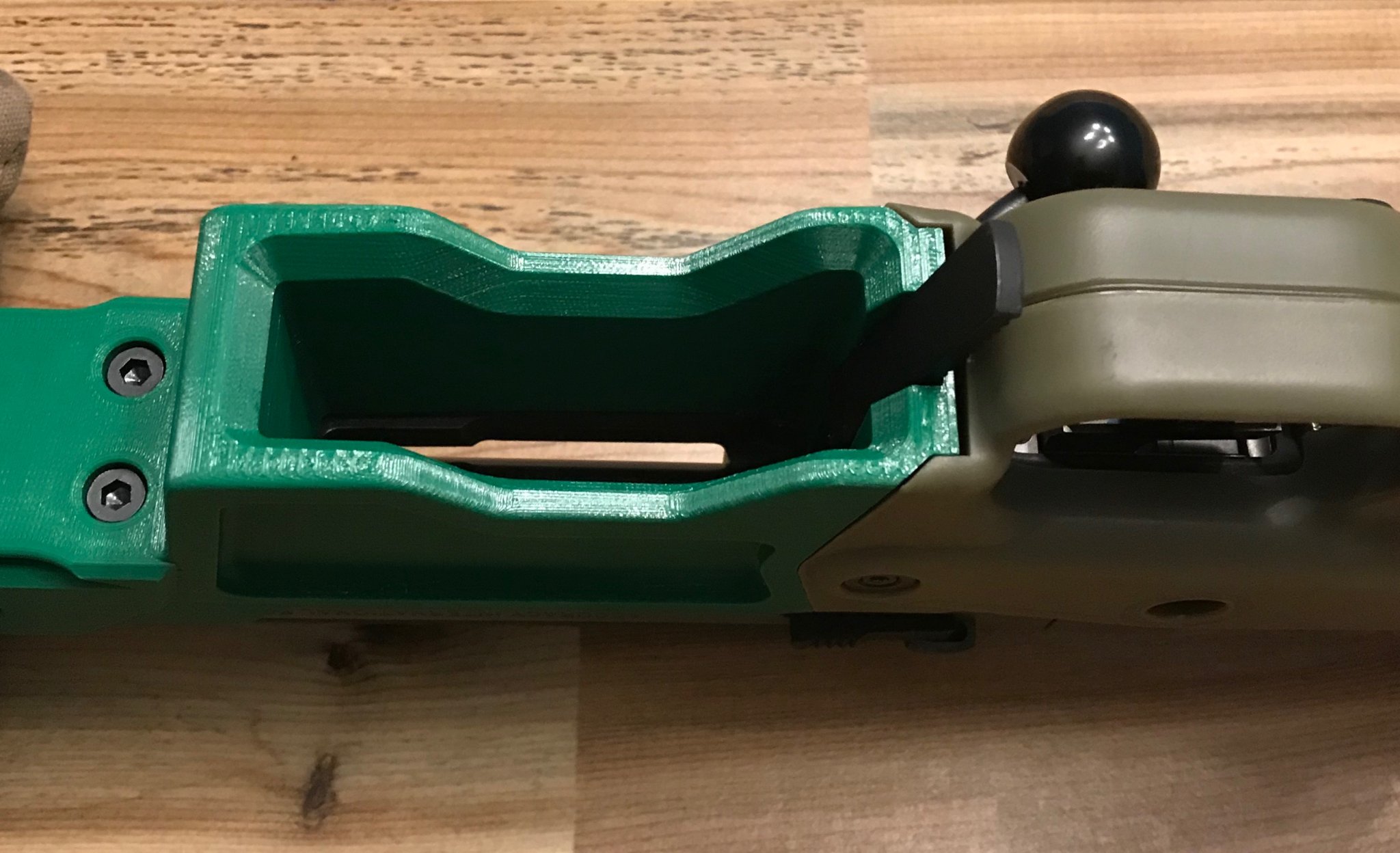

My path to get this functional prototype was to reverse-engineer both an AT chassis and an AX chassis. Once I put those in CAD, I 3D printed the "bottom metal" to verify the dimensions, fit and function. Then I designed my chassis around the bottom metal and arrived at what I believe is the perfect AI rifle for competition-oriented shooters.

In order to do this I had to de-bond my factory AX. Doing that really de-mystified the bonded action interface, and opened my eyes to the possibility of some cool options for the chassis. The design intent of this chassis is to be epoxied to the action - just like the factory rifles are. I think that there is some magic in the bonded action, and didn't want to shoehorn something around it like the MPA chassis does with the AT. This chassis is designed to be completely functional when bonded to the action, and the accessories are designed around it. That being said, if bonded it will only work with the current generation of rifles that have the Quick-Loc barrel change system.

The feature list is long, and I think it encompasses almost anything a match shooter would be looking for:

Sam

Accuracy Obsession, LLC

AI Evolution

Comparison to AT

Comparison to AX

Flared Magwell

Internal Weights and Spigot

Full build

Shown here is the final plastic 3D printed prototype of my 100% self-designed Obsession Chassis. The next real step is to complete the drawings and get one of these machined for testing. I'm not entirely sure where I will get one machined, and I know one-offs are very expensive, but I need to test an aluminum version before I would ever consider making more and offering them to other shooters.

My path to get this functional prototype was to reverse-engineer both an AT chassis and an AX chassis. Once I put those in CAD, I 3D printed the "bottom metal" to verify the dimensions, fit and function. Then I designed my chassis around the bottom metal and arrived at what I believe is the perfect AI rifle for competition-oriented shooters.

In order to do this I had to de-bond my factory AX. Doing that really de-mystified the bonded action interface, and opened my eyes to the possibility of some cool options for the chassis. The design intent of this chassis is to be epoxied to the action - just like the factory rifles are. I think that there is some magic in the bonded action, and didn't want to shoehorn something around it like the MPA chassis does with the AT. This chassis is designed to be completely functional when bonded to the action, and the accessories are designed around it. That being said, if bonded it will only work with the current generation of rifles that have the Quick-Loc barrel change system.

The feature list is long, and I think it encompasses almost anything a match shooter would be looking for:

- Single piece of machined aluminum (either 6061-T6 or 7075-T6)

- Compatible with AT and AX short actions, ambidextrous for either RH or LH

- Compatible with either AT or AX buttstock, fixed or folder (including thumb hole skins ?)

- Uses AW magazines and AT mag catch lever (AX mag catch lever is different and will not work)

- Generously flared mag well for easy magazine insertion and removal

- 12.75" forend (measured from action face)

- Forend length ensures the user can screw/unscrew a barrel as short as 16". A longer forend is certainly possible, but would increase the minimum barrel length.

- Integrated full-length RRS-dovetail

- M-Lok standard mounting interface on sides and bottom

- Proprietary dovetail-stop screw system

- Barrel channel and accessories allow 1.25" dia. straight-taper barrel with 0.050" minimum clearance per side

- Integrated non-rotating flush cup mount on both sides.

- Bipod spigot bolts directly to chassis, and adds 3" of length in addition to being 1/2" closer to the bore-axis. Spigot has an M-Lok attachment point for easy mounting of 3 or 5-slot picatinny rail.

- Internal weight system allows the user to add up to 1.25# of weight, without interfering with the M-Lok mounts or barrel clearance.

- NV bridge allows user to wrap "thumb over bore," and has mounting points for picatinny rails or other attachments. NV bridge can be positioned front to back via the side screw holes, and the orientation of the bridge itself can be flipped depending on user preference.

Sam

Accuracy Obsession, LLC

AI Evolution

Comparison to AT

Comparison to AX

Flared Magwell

Internal Weights and Spigot

Full build

Last edited: