I have Ar 10 6.5cm with a proof barrel that cycles factory Hornady loads perfectly. It will not cycle my hand loads. I’ve narrowed the issue down to my le Wilson full length die. It’s not sizing the lower body of the brass enough cause it to fit tight in the barrel. I’ve read that small base dies will correct this. I’ve also read that other full length dies like Forster size a bit more. Could anyone confirm this? Any advice would be greatly appreciated.

- Thread starter David.eckert

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Because of the more rapid feeding cycle of a semi-automatic feeding issue can arise. Small Base sizing dies were designed to help resolve this issue by bringing the brass back closer to SAAMI minimum spec.

Did you use some kind of comparator to measure shoulder bump? Are you 100% sure your issue is at the case web and not because of not bumping the case shoulder back enough? 98% of the time, chambering issues are from not enough shoulder bump.

I reload for about a dozen different rifle calibers. The only time I've actually needed a S/B die was with a Styer SSG 69. It would not chamber any case that had a case web diameter above .469". I had two RCBS S/B dies that wouldn't correct the base. I finally was able to correct the issue with a Redding S/B Body that sized the web to .4685".

For that SSG 69, It took a lot of measuring the case web to figure this out. All of my other chambering issues in other rifles were due to the case shoulder not being bumped back enough. Shoulder bump needs to be measured with some sort of a gauge or comparator that gives good measurements.

If the case web is your issue, you need to try a S/B die. Unfortunately, Redding doesn't make a S/B Body die in 6.5 Creedmoor.

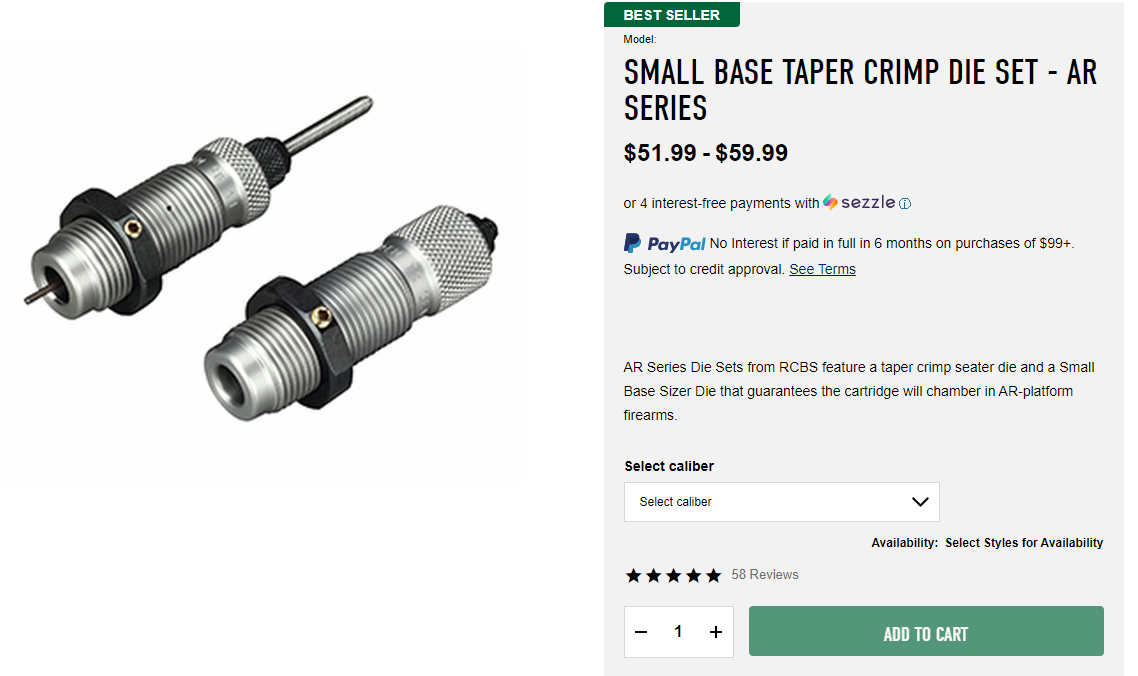

RCBS does make an AR series S/B die set for the 6.5 CM.

I reload for about a dozen different rifle calibers. The only time I've actually needed a S/B die was with a Styer SSG 69. It would not chamber any case that had a case web diameter above .469". I had two RCBS S/B dies that wouldn't correct the base. I finally was able to correct the issue with a Redding S/B Body that sized the web to .4685".

For that SSG 69, It took a lot of measuring the case web to figure this out. All of my other chambering issues in other rifles were due to the case shoulder not being bumped back enough. Shoulder bump needs to be measured with some sort of a gauge or comparator that gives good measurements.

If the case web is your issue, you need to try a S/B die. Unfortunately, Redding doesn't make a S/B Body die in 6.5 Creedmoor.

RCBS does make an AR series S/B die set for the 6.5 CM.

Learning to inspect your brass isn't difficult and doesn't require much in terms of homework or instruments.

I advise anyone who takes on bottleneck rifle loading to learn how to inspect their brass and buy the Go-Gage, tools and instruments to do this, but I can also spend your money fast if you listen very long....

Learning to inspect your chamber and dies takes a little more effort, more time and more money.

If you wan to learn to debug this in general, the forum can give you some homework and a shopping list that will take some time and a credit card.

If you want to have your chamber and die inspected without tooling up or doing that homework, you can enlist a qualified gunsmith.

(It would be fair to ask whoever chambered that barrel for help as well.)

If you just want to cut to the chase, it is low risk to just get the Small Base die and have it over with.

https://www.rcbs.com/dies-and-shell...base-taper-crimp-die-set---ar-series/780.html

The last option, is to commission your own custom die. That takes even more time and more money.

You could also just collect and sell your once-fired brass and keep buying factory or use virgin brass to tailor your own loads.

It is all up to you how much time and effort you want to invest.

The middle ground is what I advise. At least learn to inspect your ammo, and be prepared to get a small base die when you take on autoloaders.

YMMV

I advise anyone who takes on bottleneck rifle loading to learn how to inspect their brass and buy the Go-Gage, tools and instruments to do this, but I can also spend your money fast if you listen very long....

Learning to inspect your chamber and dies takes a little more effort, more time and more money.

If you wan to learn to debug this in general, the forum can give you some homework and a shopping list that will take some time and a credit card.

If you want to have your chamber and die inspected without tooling up or doing that homework, you can enlist a qualified gunsmith.

(It would be fair to ask whoever chambered that barrel for help as well.)

If you just want to cut to the chase, it is low risk to just get the Small Base die and have it over with.

https://www.rcbs.com/dies-and-shell...base-taper-crimp-die-set---ar-series/780.html

The last option, is to commission your own custom die. That takes even more time and more money.

You could also just collect and sell your once-fired brass and keep buying factory or use virgin brass to tailor your own loads.

It is all up to you how much time and effort you want to invest.

The middle ground is what I advise. At least learn to inspect your ammo, and be prepared to get a small base die when you take on autoloaders.

YMMV

Yes I measured the bump with two methods. The shoulders. I can actually feel it resisting towards the base of the brassDid you use some kind of comparator to measure shoulder bump? Are you 100% sure your issue is at the case web and not because of not bumping the case shoulder back enough? 98% of the time, chambering issues are from not enough shoulder bump.

I reload for about a dozen different rifle calibers. The only time I've actually needed a S/B die was with a Styer SSG 69. It would not chamber any case that had a case web diameter above .469". I had two RCBS S/B dies that wouldn't correct the base. I finally was able to correct the issue with a Redding S/B Body that sized the web to .4685".

For that SSG 69, It took a lot of measuring the case web to figure this out. All of my other chambering issues in other rifles were due to the case shoulder not being bumped back enough. Shoulder bump needs to be measured with some sort of a gauge or comparator that gives good measurements.

If the case web is your issue, you need to try a S/B die. Unfortunately, Redding doesn't make a S/B Body die in 6.5 Creedmoor.

RCBS does make an AR series S/B die set for the 6.5 CM.

I’m at about.005” off the fire formed. I was hoping to stay away from the kit with the crimping. Im shooting lasers and didn’t want to sacrifice any accuracy.

I don't own a 6.5 CM AR, but load for them. I'm not sure if you can get just the sizer without buying the kit, but the homework is left to the students...I was hoping to stay away from the kit with the crimping.

You might want to take a look at the Cortina mandrel die. It sizes the base down about .0005 smaller than the standard sizing die, that may be enough to solve your issues. You don't have to run it with a mandrel but you do need to lube the case a little bit. It really depends on your reloading process.

Similar threads

- Replies

- 1

- Views

- 157

- Replies

- 139

- Views

- 4K

Reloading Equipment WTS LE Wilson Full Length Bushing Die - 6 Dasher

- Replies

- 2

- Views

- 203

- Replies

- 171

- Views

- 2K