Does anyone know of anyplace that can make a new collet for the Lee collet neck sizing die. I'm sure it would be easy enough for someone with the machine tools to do it, I don't really have anything local so I'm asking here. I'm sure I'm not the only one (maybe I am!) that hates the new style collet Lee uses that doesn't size the whole neck. It leaves the case mouth unsized and even after the bullet is seated it is still flared on the very end. I don't "neck size" but use it sometimes when it's needed, like when you don't get a complete fire form, or to fix a neck when needed. Many uses for the reloader besides strictly neck sizeing alone. I try to have one for every chamberfing I load for. Thanks for any help!

- Thread starter axarob44

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

At one point in time, before the elections and Covid... they would get you one without the modification on a special order basis. I haven't poked them in many years, but one idea would be to ask them. You never know, maybe they will say yes, or maybe they will say no, but at least give that a try and see what they say?

Fabricating the parts from scratch isn't a big deal if you have the shop and the budget, but it will take a fuss if you don't have the shop resource.

Fabricating the parts from scratch isn't a big deal if you have the shop and the budget, but it will take a fuss if you don't have the shop resource.

Thank you RegionRat for the reply. Unfortunately I did speak with them this afternoon and was told they don't make the old style anymore since the machine is set up for the new style. I can't really say why this bugs me so much but to me I can't see the added benefit. It creates more problems than it solves. What do I know though. It was a good tool and Lee isn't putting to many "good" tools out these days.

I've never seen that particular Lee die, so I'm thinking this isn't directly applicable, but it may give you some ideas;

I use L.E. Wilson Neck sizing dies. The "button" (that sizes the case neck) is interchangeable with different diameter buttons. Most importantly, they are all tapered, bottom (wider) to top (narrower). If the button is installed with the "size marking" up/so that you can see the numbers, the button will taper the neck. If you pull the button out, flip it over so that the numbers are down, and re-insert it, the die/button will not taper the case neck.

I use L.E. Wilson Neck sizing dies. The "button" (that sizes the case neck) is interchangeable with different diameter buttons. Most importantly, they are all tapered, bottom (wider) to top (narrower). If the button is installed with the "size marking" up/so that you can see the numbers, the button will taper the neck. If you pull the button out, flip it over so that the numbers are down, and re-insert it, the die/button will not taper the case neck.

Who even uses Lee neck collet dies anyway? Just Fudds and Rednecks is all.

I may be a redneck lol! I think that collet neck die was a pretty good tool. It has it's uses.

Heh, heh. I could actually be both depending upon who’s looking. Don’t care either. Neck collet dies have their place in the hobby for sure. I wasn’t aware that they’d changed the design. It’s a good piece of info to know.I may be a redneck lol! I think that collet neck die was a pretty good tool. It has it's uses.

ML McPherson is the guy that pushed for the new design. Seems kind of fuddy to me.

I use lee collet on many rifles. I think it’s the simplest and most underrated die out there. .0015” neck tension and little runout. No donuts etc

I use the old design though. Didn’t realized they changed and this new stuff doesn’t sound very appealing

I use the old design though. Didn’t realized they changed and this new stuff doesn’t sound very appealing

My .308 Win Collet die even with brass trimmed to SAAMI recommended length sticks out from the die further than that picture. I get the idea. They say it's unsized but in reality it turns in to more of a flare than just unsized because it is still flared after seating the bullet. I can't say its happened to me yet but some look flared enough that they might catch on a semi auto feed ramp.

I'd post a picture but I already pulled them apart.

On the exposed portion of the neck if it's unsupported on the outside when you squeeze it it's going to flare out, not just nicely bend in all square like they expect. The seated bullet doesn't iron it out straight.

Maybe mine is defective? Too short?

I've even tried to use my Redding competition shell holders largest size and it still does the same.

I'd post a picture but I already pulled them apart.

On the exposed portion of the neck if it's unsupported on the outside when you squeeze it it's going to flare out, not just nicely bend in all square like they expect. The seated bullet doesn't iron it out straight.

Maybe mine is defective? Too short?

I've even tried to use my Redding competition shell holders largest size and it still does the same.

Last edited:

And the problem with brass is?Does anyone know of anyplace that can make a new collet for the Lee collet neck sizing die. I'm sure it would be easy enough for someone with the machine tools to do it, I don't really have anything local so I'm asking here. I'm sure I'm not the only one (maybe I am!) that hates the new style collet Lee uses that doesn't size the whole neck. It leaves the case mouth unsized and even after the bullet is seated it is still flared on the very end. I don't "neck size" but use it sometimes when it's needed, like when you don't get a complete fire form, or to fix a neck when needed. Many uses for the reloader besides strictly neck sizeing alone. I try to have one for every chamberfing I load for. Thanks for any help!

what do you mean?And the problem with brass is?

Google claims..."natural flare"

About 3,850,000 results (0.48 seconds)

About 3,850,000 results (0.48 seconds)

Search Results

Featured snippet from the web

This often-requested modification was implemented in 2019. This change allows the portion of the neck that protrudes above the Collet to remain in its fire formed condition. This provides a natural flare to the case neck allowing easy and concentric seating of bullets.Just put a slight crimp on it and rock on…

I use Lee collet dies on several rifles…. Then use a Redding body die…

Works for me

I use Lee collet dies on several rifles…. Then use a Redding body die…

Works for me

Seems like the only way to correct that leftover mouth flare from the new collet die is to follow up with Lee's Factory Crimp Die set to just flatten out the flare. Kinda sucks because it adds an extra step to the process.

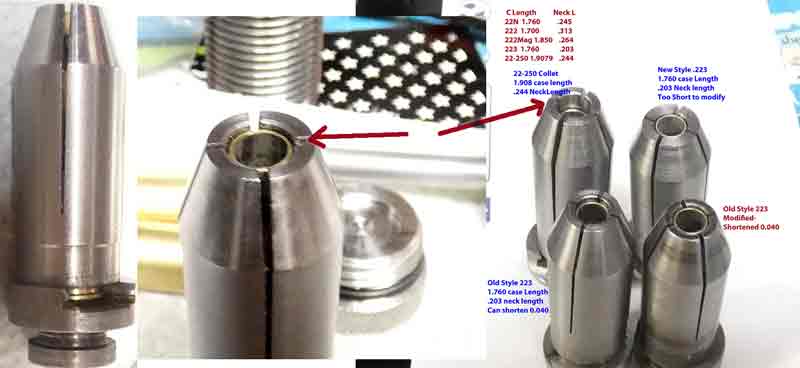

The pics posted earlier in this thread point towards the later collet fingers just being shorter.

If Lee continues to only offer the new setup, they will lose business for sure. Customers will be driven to a custom neck honed Forster sizing die followed up by a neck sizing mandrel.

The pics posted earlier in this thread point towards the later collet fingers just being shorter.

If Lee continues to only offer the new setup, they will lose business for sure. Customers will be driven to a custom neck honed Forster sizing die followed up by a neck sizing mandrel.

Last edited:

Yep, It does add more steps just like Lee telling me to just use a washer, that gets old after 10 cases throwing that washer over the case every time.Seems like the only way to iron out that leftover mouth flare from the new collet die is to follow up with Lee's Factory Crimp Die set to just flatten out the flare. Kinda sucks because it adds an extra step to the process.

Since many folks run the case into the LCD, back out, rotate some and hit it again,

why not a slotted washer to size to the end of the neck for the second hit?

why not a slotted washer to size to the end of the neck for the second hit?

I'll try it with a slotted washer, see if it's a pain to fumble with, maybe won't be too bad. Maybe I'll make a special shell holder.

What is the problem with the very slight flare on the mouth and what is the effect on target?what do you mean?

It’s the feeding and or chambering issues that it can cause. I’ve had chambers wherein a slight flare was enough to impede chambering the cartridge. Personally, I have to believe that this was done to appease those loading cast bullets. It sucks for precision shooters though.What is the problem with the very slight flare on the mouth and what is the effect on target?

I would have thought everyone loading cast had M dies already.

THIS……

Attachments

Redneck Fudd here,

Instead of paying LEE for a custom LCD for my 22 Nosler, I modified an old style .223 die.

Looking at the case drawings, the 22N neck is longer. Shaving about 0.040" off the bottom of the collet brought the neck up for full sizing. The new style is too short.

Maybe there are other instances out there that could help with other cartridges.

30-06 neck is longer than the 308. I wonder if it could be shortened to work?

I have two old style .223 Dies, one modified, that should last me for a while.

But just in case I've modified a 22-250 collet for a back up.

Got the 22-250 LCD from midway on clearance.

Instead of paying LEE for a custom LCD for my 22 Nosler, I modified an old style .223 die.

Looking at the case drawings, the 22N neck is longer. Shaving about 0.040" off the bottom of the collet brought the neck up for full sizing. The new style is too short.

Maybe there are other instances out there that could help with other cartridges.

30-06 neck is longer than the 308. I wonder if it could be shortened to work?

I have two old style .223 Dies, one modified, that should last me for a while.

But just in case I've modified a 22-250 collet for a back up.

Got the 22-250 LCD from midway on clearance.

Last edited:

Maybe there are other instances out there that could help with other cartridges.

30-06 neck is longer than the 308. I wonder if it could be shortened to work?

I might have to look into the 30-06 idea. They're cheap enough to give it a try.

You will likely have to use the 308 mandrel with the shaved 30-06 collet.

Get an extra mandrel or two

Regular and an undersize one. $5 each to polish to the neck tension you want.

Somehow the cheap price doesn't fit with those that just want the most expensive options, or don't understand how it works.

Here's my modified LCD with about 5000 rounds (mine and the wife's).

I've had to clean, polish, lube a few times.

The wife and I are mostly shooting 22Nosler and 22 Nosgar.

A Redding Body Die to bump 6mm HAGAR brass then the LCD.

Get an extra mandrel or two

Regular and an undersize one. $5 each to polish to the neck tension you want.

Somehow the cheap price doesn't fit with those that just want the most expensive options, or don't understand how it works.

Here's my modified LCD with about 5000 rounds (mine and the wife's).

I've had to clean, polish, lube a few times.

The wife and I are mostly shooting 22Nosler and 22 Nosgar.

A Redding Body Die to bump 6mm HAGAR brass then the LCD.

Last edited:

Those dies have seen some use lol! I will post back when I get the die and I always get a couple mandrels too so I can polish them or modify the diameter. I think it makes me so mad about these things because they can be a great tool for the reloading bench. Very versatile. You would have something if you made one with proper machining and good material with an attention to detail. Instead of just pushing them out the door for $25. But, people want cheap. Especially the crowd that gravitates to Lee. They could make a lot of nice stuff if they just gave a crap about better quality.

They look worse than they are.

I blued parts to keep them separated from the 223 stuff.

I blued parts to keep them separated from the 223 stuff.

For giggles a few years ago I picked one up for 50bmg, stupid thing works better than my neck sizer that cost 4 times as much!

Thanks. I checked my new 308 die and it doesn't have the flare so I haven't noticed any difference. It seems strange that there would be an issue in feeding since the neck would be going back into the same chamber unsized.It’s the feeding and or chambering issues that it can cause. I’ve had chambers wherein a slight flare was enough to impede chambering the cartridge. Personally, I have to believe that this was done to appease those loading cast bullets. It sucks for precision shooters though.

It may seem strange, but once you’ve had an issue with it, you’ll realize why we say that.Thanks. I checked my new 308 die and it doesn't have the flare so I haven't noticed any difference. It seems strange that there would be an issue in feeding since the neck would be going back into the same chamber unsized.

I have used the Lee LCD (with a washer) in the past as a "case mouth squasher" to fix up case mouths that were peened/flared and f'ed up due to wet tumbling (the main reason why I no longer wet tumble precision cases).

I too think the "new" version of the collet is dumb, as having to slip a washer over every case to get the collet to close sooner and do what the "old" ones already did gets old fast, but it does do the trick.

IDK anyone who actually uses a Lee LCD as Lee intended (neck sizer only) anymore... but they're great for fixing up jacked up case mouths, and lots of guys still use them as a psudo-mandrel in combination with a body sizing die to great effect.

I too think the "new" version of the collet is dumb, as having to slip a washer over every case to get the collet to close sooner and do what the "old" ones already did gets old fast, but it does do the trick.

IDK anyone who actually uses a Lee LCD as Lee intended (neck sizer only) anymore... but they're great for fixing up jacked up case mouths, and lots of guys still use them as a psudo-mandrel in combination with a body sizing die to great effect.

Last edited: