So I was feeling pretty good about myself, having just returned from a local club shoot where I was spot-on ... dinging the steel out to about 1,200 yards ... and could have gone farther. My MPA 300-WM was working great, and I had a terrific cartridge that had been giving me SD's of around 5.0 and the BC for the bullet (Berger 200.20x Hybrid Target) looked to be right on the mark. Definitely the most consistently I've ever shot beyond 1,000 yards, as I was pretty much in the "One Shot - One Kill" mode.

Came home (slightly euphoric) and decided to size some brass and get ready to reproduce that load since it was about as good as I was gonna get. I spread the cases out on a cookie sheet, gave 'em a spray with Hornady One-Shot just like I always do ... although I admit in hindsight I was trying to lube a bit lighter than usual to save on spray lube as I was on my last can. I started sizing with my Redding Type-S Bushing Die, and as the first few cases felt "snug", that "Inner Voice" of mine said ... "These aren't lubed enough - stop - and give 'em another spray down."

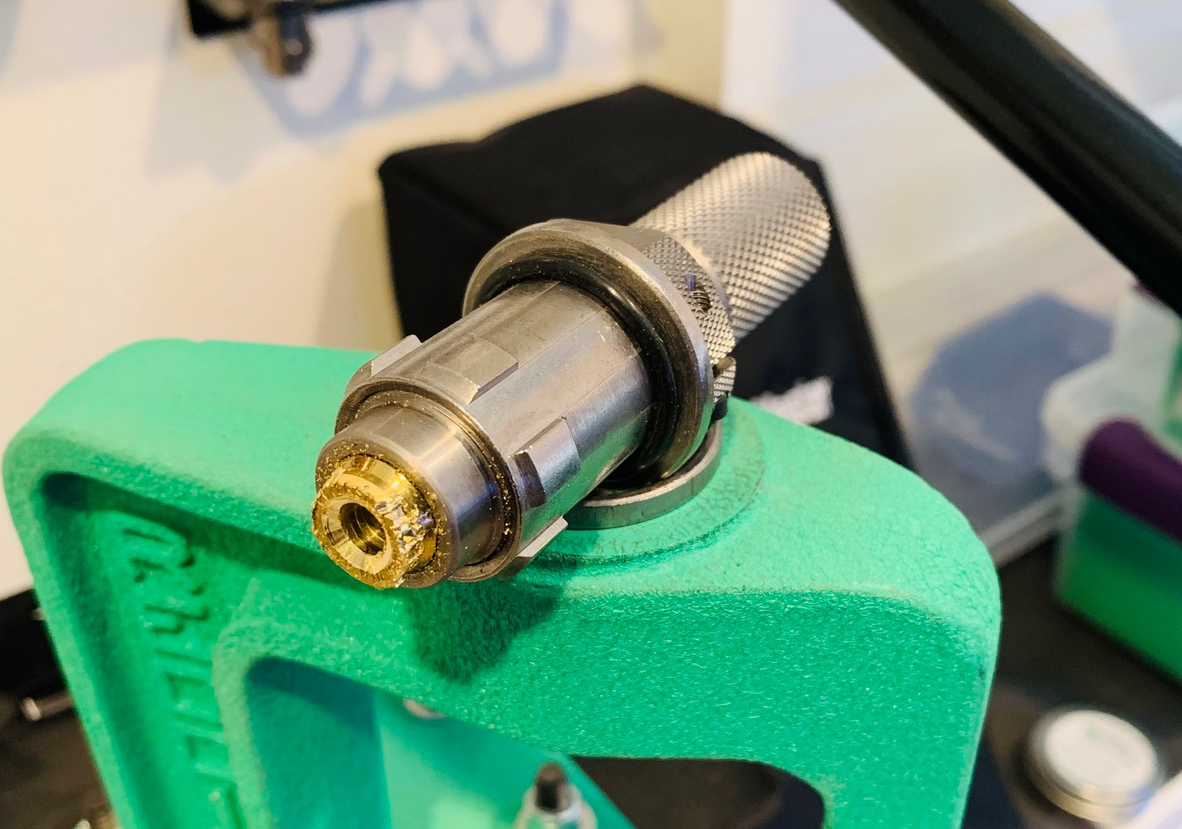

I ignored my "Inner Voice". Three cases later ...

And "Yes" ... I tried all the standard tricks (Bang from Above, Drill and Tap, Penetrating Oil, Heat, etc.). Hell, I even tried drilling out the inside of the bushing.

Luckily I found one in stock and it's headed my way. Anybody want to buy a slightly used Redding 300-WM Type-S Bushing Die? It even has a .331 bushing conveniently and permanently lodged it it. Someday, maybe I'll pick it up and try again ... but not today ... I'm too pissed off at myself. Lesson Learned !!!

Came home (slightly euphoric) and decided to size some brass and get ready to reproduce that load since it was about as good as I was gonna get. I spread the cases out on a cookie sheet, gave 'em a spray with Hornady One-Shot just like I always do ... although I admit in hindsight I was trying to lube a bit lighter than usual to save on spray lube as I was on my last can. I started sizing with my Redding Type-S Bushing Die, and as the first few cases felt "snug", that "Inner Voice" of mine said ... "These aren't lubed enough - stop - and give 'em another spray down."

I ignored my "Inner Voice". Three cases later ...

And "Yes" ... I tried all the standard tricks (Bang from Above, Drill and Tap, Penetrating Oil, Heat, etc.). Hell, I even tried drilling out the inside of the bushing.

Luckily I found one in stock and it's headed my way. Anybody want to buy a slightly used Redding 300-WM Type-S Bushing Die? It even has a .331 bushing conveniently and permanently lodged it it. Someday, maybe I'll pick it up and try again ... but not today ... I'm too pissed off at myself. Lesson Learned !!!