It’s not just LMT, but market-wide across all industries. The people who know how to do things are all dead or retired, and for whatever reasons, the skills and work ethic they had were not passed-on to the current generation of lower-skilled workers in assembly, supervision, QC, TQM, and management. Millennials are in management and even senior management now in some companies.

With my own generation (Gen X), I’ve seen a lot of business owners immediately dip into profits and go on vacation way before they should even think about it, then when the cat is away, the mice will play because solid standards and procedures were not enforced.

The workforce is also less-educated, about 100x more distracted, unable to focus or grasp basic concepts, more prone to substance abuse, psychotropic prescription medications, hormonal abnormalities from environmental factors, sleep disorders, poor nutrition driven by big food/big retail, lateness, absenteeism, and flakiness.

If you are able to buck these trends somehow in today’s workforce and establish a culture of high standards based on professional conduct, attention-to-detail, and great managers, you will be in extreme high demand.

The schools and broken families are not cranking out these kinds of people though, and have not done so for generations. Schools actually contribute to the opposite all of the key character and professional attributes that are needed in the manufacturing industry.

Then look at manufacturing wages in the firearms sector. Starting at $15/hr, and what do you expect?

$2400 gross monthly

$148.80 SSI theft

$34.80 Medicare theft

Too poor to be charged Federal Income theft

Net after Federal government theft of labor dues:

$2216.40

3 Bedroom Rent in Eldridge Iowa: $784/month

Gas to commute: $150-$200/month

Utilities: US Avg $429.33/month (Eldridge Iowa is 100.5 index compared to US, with 100 being the National index.)

$803.07

Car payment: Avg US used car payment was $488 in 2021. Used car average transaction prices have increased to over $31,000 in Sep 2022. If an entry-level manufacturing employee finds a beater at the local used car Suckers game lot, in Iowa with their State sales tax and licensing, title, and other fees, you’re looking at $357/mo payment if you put down $2000 and trade-in a rust bucket for $500 valuation.

$803.07 - $357 =

$446.07

Groceries: 1 man on thrifty budget $227

Phone bill: $167.11

$51.96

Now imagine a young manager trying to enforce proper parts fitment tolerances with guys like this working under him.

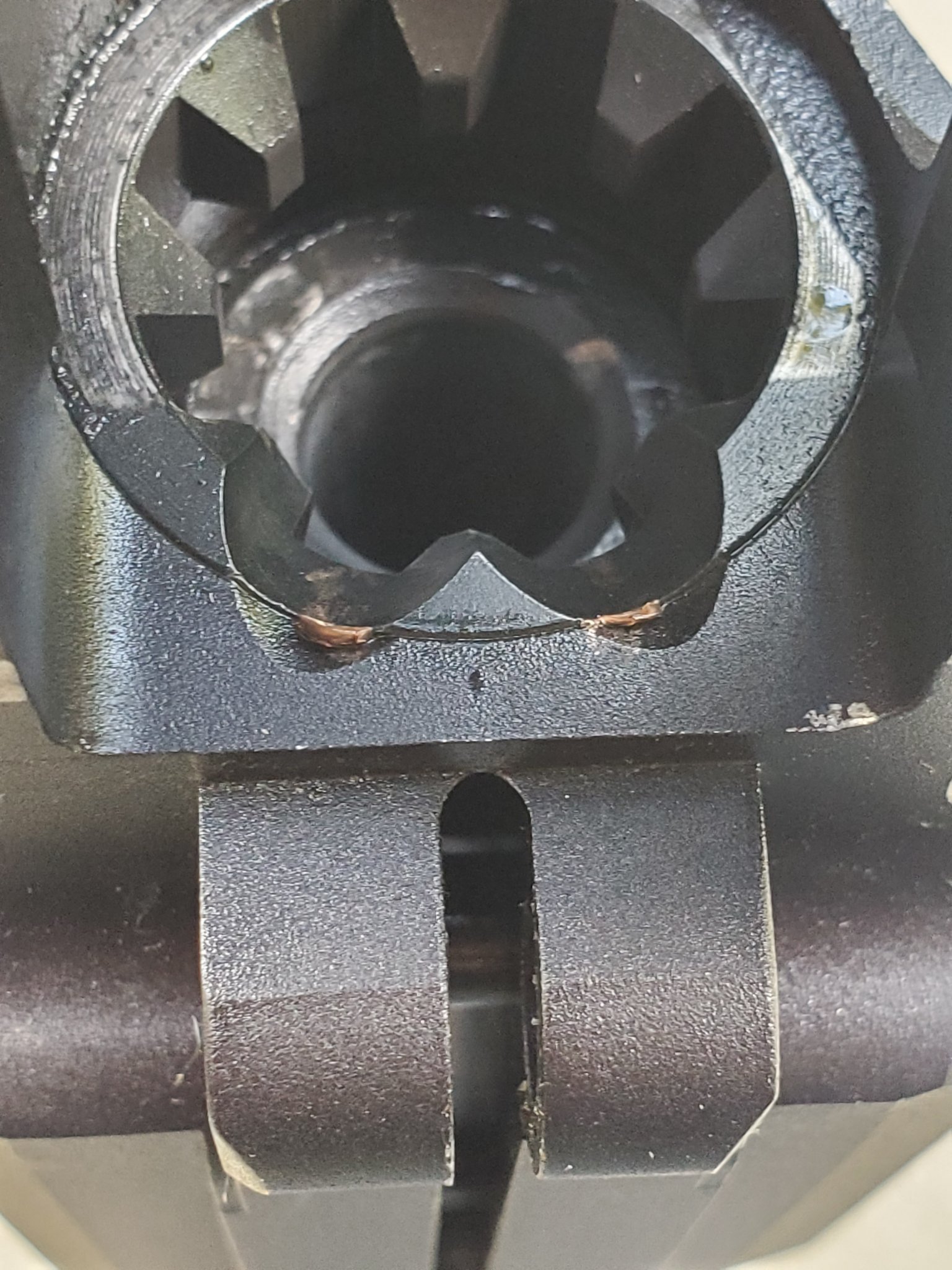

![step2-lubricate-and-test-fit-barrel-extension-with-receiver[1].jpg](/shooting/data/attachments/1435/1435028-fb08fc90edc7f91b36f47c047e33af41.jpg)