First, if you are doing load development that is likely to end up with cartridges which should not be fired for safety reasons, you should avail yourself with some way to disassemble those cartridges. Impact bullet pullers are probably adequate for a few cartridges, but they can be a chore for larger numbers, and they are not kind to plastic bullet tips. After decades of handloading I have obtained a set of collet bullet pulling dies, and I now clearly recognize that I should have bought them far sooner.

I don't expend a lot of effort on seating depths. Using the permanent marker on the bullet method, I find my shortest seating depth to reach the lands, and then reduce that length so I can be certain all bullets jump at least .010". Yes, there are accuracy advantages to getting more precise about that, but for my purposes they are small enough for me to just simply forego them in the long run. If magazine feeding is a serious consideration, then it's also my only one.

I choose a primer that is most easily available and adequate for the intended task, and leave it at that.

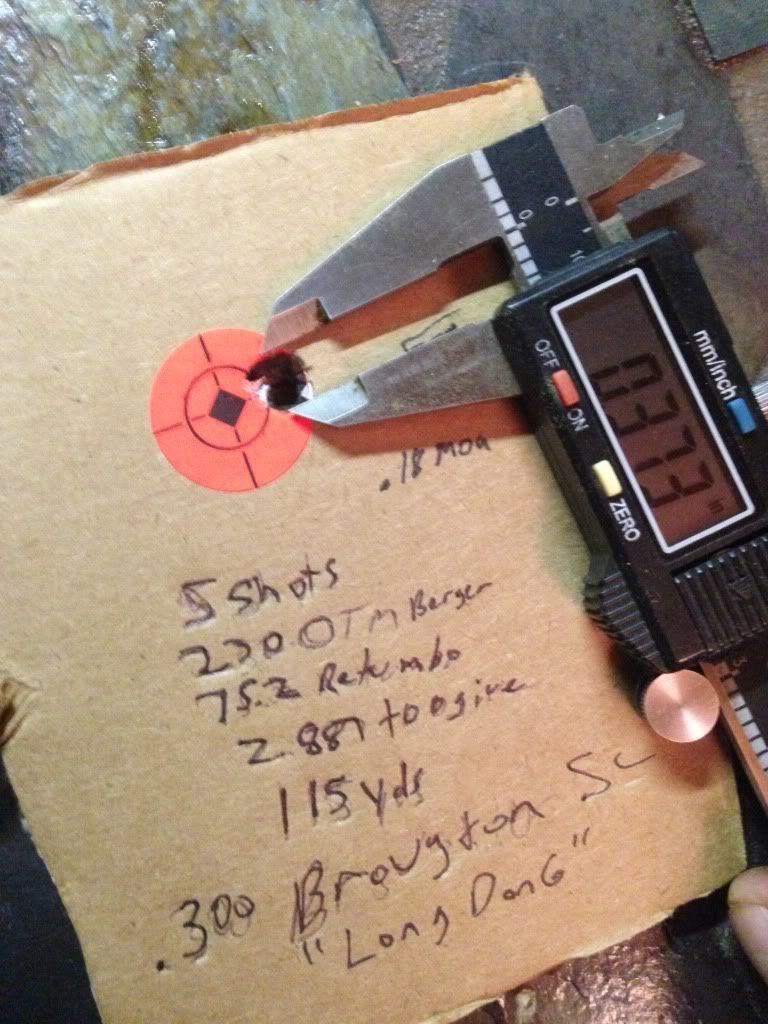

My main effort is geared toward finding a good charge weight. I determine this by load testing. If the load is going to be used in a hot barrel, as when shooting matches, then I do my load testing with a hot barrel. If the match's course of fire requires a relatively rapid firing cadence, then the testing must replicate that firing cadence. All of these factors and more are critical to successful load development. A load doesn't just need to match a barrel, it also needs to match the way that barrel is intended to be used.

Once you 'find' a charge weight, confirm it with a large batch of test loads. Try some with .1gr more and .1gr less, just to confirm it's as good as it needs to be; don't make the mistake of basing the assembly of large batches of ammo on a shaky charge weight finding.

Understand clearly that load development is a necessary but subtly evil task which should be kept to a minimum. Seeking load perfection makes little sense if it is done at the expense of a significant potion of the intended barrel's bore life.

If, heavens forbid, you are forced to change a load, break down any unfired batches of the old one and repurpose the components to the new load. There's few things more pointless than hanging onto handloaded ammo you don't really want to shoot, and/or subjecting the bore to the punishment of simply 'using up the old, bad ammo'. That is definitely not a good bore preservation strategy.

In the past, I have tried following a practice of developing loads for different distances. What I have found is that in almost all cases, the longer range load is also very much a good one for the shorter distances.

I find that the bullets and necks tend to bond together after assembly, changing the neck tension/pullet pull value and often rendering a good load less accurate. For this reason I only maintain minimal stocks of assembled ammo, the components last a lot longer in their individual packaging. I only make ammo shortly in advance of specific needs, like an upcoming match, or at the beginning of a hunting season, and I break unused stuff back down to components, so any stocks of bonding-compromised ammo is kept at a minimum, or better yet, none at all.

Mostly, for hunting, I just go with factory ammo. I don't hunt enough to justify the added effort and expense of load development. It works, certainly well enough for the likes of me. I prefer Hornady Superformance SST and Remington Core-Lokt Express.

I believe that the sooty/etc. residues in fired case necks are at least partially to blame for this bonding, and am investing in an ultrasonic cleaning process with stainless steel media to eliminate their presence in my cases before reloading.

In essence, simplicity needs to be a primary goal. Specialization is for insects. Reduce your calibers, loads for each gun, and handloading techniques down to the ones that provide the most usage for the least effort and cost. Over the years, my firearms collection has become smaller and more specific, based on cool evaluations of needs and capabilities. I define tasks, and then provide a needed capability. Duplication is ultimately unsatisfying, finding multiple uses for a common implement is praiseworthy. Whims are for schoolgirls.

The only press I have ever owned is a Dillon RL550B, and a used one at that. It's clearly excessive for a new guy, but one grows into it, and faster because it's such a good one. For the longer haul, it's just plainly become one of my key necessities.

For a newbie, some of this stuff can be a bit excessive, so take it with a grain of salt, and keep it in mind for somewhere down the road.

In over 20 years of handloading I have practically never found a load that works really well in any gun other than the one it was developed for. Coincidences may happen, but apparently, not to me. I don't consider a universal load to be a viable goal. All such loads are ultimately compromises, and a load individually matched/optimized to a specific rifle will almost certainly always best them. But I have also still failed to find loads that beat the pants off FGMM.

Greg