So I have one of the PSA Sabres m110 ish in 6.5 Creed on the way. I have about 80 rounds to run through it as a break in, then I will start load development. I've not done a real load development in a semi auto so my question: since it's easy to turn off and on with this rifle, should I turn it off for development to get a better picture with SD and ES?

- Thread starter EscapeVelocity

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What components do you have?

Part of the fun of load testing for a gas gun is function. Test for function first, tweak for accuracy from there.

I prefer a collet crimp for semi-autos.

I prefer a collet crimp for semi-autos.

Yea I'll be testing function in that first 80. After that I'll be using lapua brass, h4350, cci 450s, and 140 Elds.

Yea I'll be testing function in that first 80. After that I'll be using lapua brass, h4350, cci 450s, and 140 Elds.

The biggest issue you need to take into consideration when reloading for a Gasser is proper neck tension. Run a piece of your Lapua Brass in your FL sizing die and make a generic 2.80 dummy round, then take a measurement with your calipers from the Ogive.

Insert that dummy in a mag and chamber it by releasing the Bolt Catch, extract the dummy around and then measure from the Ogive again and see if the bullet has moved forward from the inertia of the BCG slamming it forward and chambering.

If you're Ogive measurement changes by chambering the round you need to increase the tension on the neck.

Also reloading for a semi-auto is a completely different animal from bolt action guns because you won't get anywhere near MAX Load before you start to see pressure signs from the ejector and extractor.

This is exactly the kind of thing I'm looking for, and wouldn't have thought of it. I'm currently running a .2625 mandrel for neck tension and see how that does, if not what do you recommend?The biggest issue you need to take into consideration when reloading for a Gasser is proper neck tension. Run a piece of your Lapua Brass in your FL sizing die and make a generic 2.80 dummy round, then take a measurement with your calipers from the Ogive.

Insert that dummy in a mag and chamber it by releasing the Bolt Catch, extract the dummy around and then measure from the Ogive again and see if the bullet has moved forward from the inertia of the BCG slamming it forward and chambering.

If you're Ogive measurement changes by chambering the round you need to increase the tension on the neck.

Also reloading for a semi-auto is a completely different animal from bolt action guns because you won't get anywhere near MAX Load before you start to see pressure signs from the ejector and extractor.

Also should I not worry about shutting off the gas to develop a load?

I wouldn't turn off the gas for load development.

I would want my results to come from proper function and cycling, as the firearm is meant to be used.

I would make sure to thoroughly clean the OEM sticky packing oil from the whole rifle. And be sure to clean the bore and chamber.

And consistent neck tension also makes for consistent results. I have seen plenty of great loads go to poop after the neck loosen's up.

I would want my results to come from proper function and cycling, as the firearm is meant to be used.

I would make sure to thoroughly clean the OEM sticky packing oil from the whole rifle. And be sure to clean the bore and chamber.

And consistent neck tension also makes for consistent results. I have seen plenty of great loads go to poop after the neck loosen's up.

I use a collet crimp for semi autos.

Chris, I have found my seating depth could change when chambering a round when using only my bushing die. I ordered a lee fcd die and things improved quite a bit it eliminated a random flier I would get. I think it’s from the seating depth change and maybe a little more time in the case to get a consistent burn. I also have found the the rifle changed a few times accuracy wise up until a couple hundred rounds or so, they seemed to get more consistent when the action started to not feel gritty from not being broken in. So don’t get discouraged until a couple hundred rounds or so, I wouldn’t give up until 500 rounds personally if I wasn’t getting good results. I think the rifle is getting inconsistent vibrations and such from all the high spots in the upper in the bcg area, until they’re all smoothed out the rifle dynamics are constantly changing, because the “high spots” are getting worn with each cycle, that and the gas port is constantly changing until it gets smoothed out. I highly recommend considering a Kynshot hydraulic buffer with a tubbs flat wire spring, man did that really tame the rifle down and made it a pussy cat to shoot. Also if you get severely craters primers or pierced primers, or if you just want a nice bcg, get the tool craft high pressure 6.5 creed bcg with the diamond coating, i went from a few pierced primers, cratered primers and early pressure signs, to being able to run a 130 Berger hybrid to max bolt action loads and brass that looks like it come out of a custom bolt action. My old bolt set up, absolutely beat the hell out of my brass with mid range loads. It’s unreal the difference.

Last edited:

Yea I'll be testing function in that first 80. After that I'll be using lapua brass, h4350, cci 450s, and 140 Elds.

Off the top of my head 41.5-42 and play with seating depth. I think 2.78 is where the factory ones are.

Just checked a box it says 41.5 and 2.810 with 140eld.

That's very good to know! I may have to get with you if I run into problems. If this psa barrel won't shoot, I'll be looking for a barrel, and trying to keep it on the shorter side at around 18".Chris, I have found my seating depth could change when chambering a round when using only my bushing die. I ordered a lee fcd die and things improved quite a bit it eliminated a random flier I would get. I think it’s from the seating depth change and maybe a little more time in the case to get a consistent burn. I also have found the the rifle changed a few times accuracy wise up until a couple hundred rounds or so, they seemed to get more consistent when the action started to not feel gritty from not being broken in. So don’t get discouraged until a couple hundred rounds or so, I wouldn’t give up until 500 rounds personally if I wasn’t getting good results. I think the rifle is getting inconsistent vibrations and such from all the high spots in the upper in the bcg area, until they’re all smoothed out the rifle dynamics are constantly changing, because the “high spots” are getting worn with each cycle, that and the gas port is constantly changing until it gets smoothed out. I highly recommend considering a Kynshot hydraulic buffer with a tubbs flat wire spring, man did that really tame the rifle down and made it a pussy cat to shoot. Also if you get severely craters primers or pierced primers, or if you just want a nice bcg, get the tool craft high pressure 6.5 creed bcg with the diamond coating, i went from a few pierced primers, cratered primers and early pressure signs, to being able to run a 130 Berger hybrid to max bolt action loads and brass that looks like it come out of a custom bolt action. My old bolt set up, absolutely beat the hell out of my brass with mid range loads. It’s unreal the difference.

I made those 80 rounds at 41.4 of H4350 at 2.800, so they may shoot decent for break in rounds.Off the top of my head 41.5-42 and play with seating depth. I think 2.78 is where the factory ones are.

Just checked a box it says 41.5 and 2.810 with 140eld.

Anytime brother. Let me know how you like that trigger. I’m putting together a 20” .308 now and I’m still deciding on a trigger.That's very good to know! I may have to get with you if I run into problems. If this psa barrel won't shoot, I'll be looking for a barrel, and trying to keep it on the shorter side at around 18".

My JP had trouble with Lapua brass due to its neck thicknes was causing over pressure. After you fire a few rounds see if you can slide a bullet back into the cartridge. I turned the necks and the problem went away.

As to load development, I do a work up for the charge weight to find the smallest group and then instead of seating depth testing I use a tuner/break to fine tune the load.

As to load development, I do a work up for the charge weight to find the smallest group and then instead of seating depth testing I use a tuner/break to fine tune the load.

I spoke with SAC regarding neck tension and the feedback I received was that they suggested up to .004" of neck tension(gasgun). That advice coupled with what I learned I have been using neck tension only for some time with great results; with a small variety of bushings to suit the different brass I run.

I have not had any of my ogive or coal measurements change during chambering with a variety of bullets using this approach.

You can look at factory loads for one that will shoot well, then gather data off that round and work from there to find load data. See how the brass is sized, etc.

I have had better luck with 130-136 grn bullets not causing pressure issues.

I have not had any of my ogive or coal measurements change during chambering with a variety of bullets using this approach.

You can look at factory loads for one that will shoot well, then gather data off that round and work from there to find load data. See how the brass is sized, etc.

I have had better luck with 130-136 grn bullets not causing pressure issues.

I'm really intrigued by the 123 grain bullets and trying to generate as much speed as I can with them. I may try the Sierras or Lapuas.

If I didn’t have my 7-08 running 120gr I’d get a man bun gas gun!  Still might.

Still might.

Get the rig shooting with the feel of a bolt gun. I mean to say, pull the trigger and you don’t feel the bolt flying back & forth. This can wreak havoc on groups. This puts the gas setting throwing brass 2:45 on a clean gun & 3:00 after approx 15rnds.

Get the rig shooting with the feel of a bolt gun. I mean to say, pull the trigger and you don’t feel the bolt flying back & forth. This can wreak havoc on groups. This puts the gas setting throwing brass 2:45 on a clean gun & 3:00 after approx 15rnds.

I load a grain to a grain and a half less powder in my gasgun loads than I do my bolt guns and I do not use hot bolt gun loads to begin with. I’ve found the large frames are much easier to shoot this way. Maybe because of the reasons you mentioned.If I didn’t have my 7-08 running 120gr I’d get a man bun gas gun!Still might.

Get the rig shooting with the feel of a bolt gun. I mean to say, pull the trigger and you don’t feel the bolt flying back & forth. This can wreak havoc on groups. This puts the gas setting throwing brass 2:45 on a clean gun & 3:00 after approx 15rnds.

Yup, I used the Hornady Service Rifle loads as a baseline for 308 starting out. Generally the 1-1.5gr less works across the board. 6.5CM operates at less pressure for that 2700fps ave. Probably be a sweetheart in AR10 with less reduction in powder. Just a SWAG tho.I load a grain to a grain and a half less powder in my gasgun loads than I do my bolt guns and I do not use hot bolt gun loads to begin with. I’ve found the large frames are much easier to shoot this way. Maybe because of the reasons you mentioned.

I made those 80 rounds at 41.4 of H4350 at 2.800, so they may shoot decent for break in rounds.

I recently just finished up load development for one of my Customs that ill be doing a review on here for JP, I went with a 24" Bartlein instead of my usual 22".

The rifle performs quite well between 40 - 41grs of H4350 with the 140 Elds. I settled on 40.3grs for this 24" Barrel. The rest of my 6.5CM's from 18"-22" all seem to shoot the same load of 40.4grs equally well with the 140 ELD.

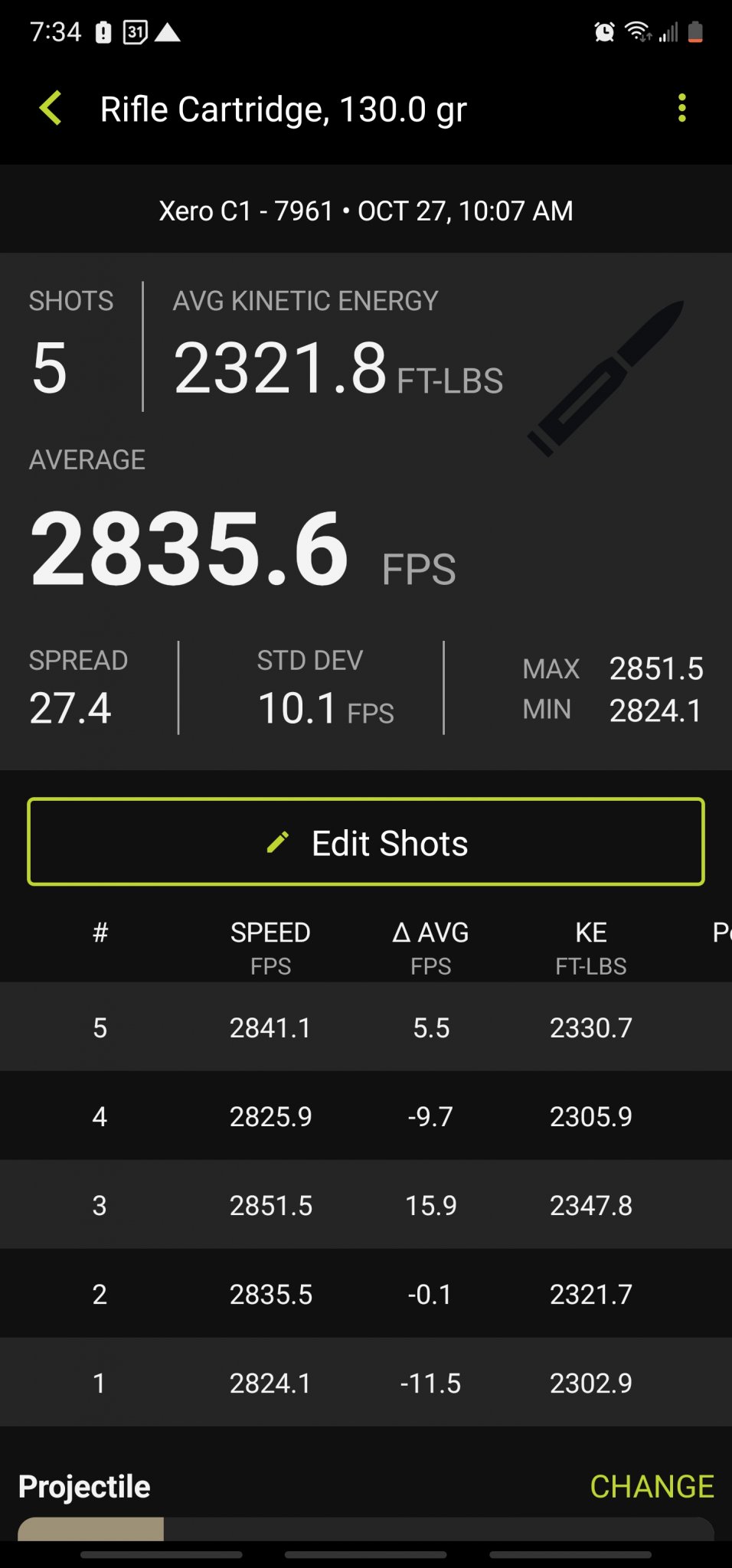

Now that I've established my load for the 140 ELD I'll be moving on to the 147 ELD and the Berger 130 AR Hybrid that I'm intentionally going to push as hard as I can to see if I can come close to 3000fps with the 130 and still maintain a low SD and ES.

Great looking groups. Gives me hope for my gasser and the fact that I might be able to get low numbers as well. What's your plans to push the 130s so fast? I'm considering trying the 123s and 130s for speed as well.I recently just finished up load development for one of my Customs that ill be doing a review on here for JP, I went with a 24" Bartlein instead of my usual 22".

The rifle performs quite well between 40 - 41grs of H4350 with the 140 Elds. I settled on 40.3grs for this 24" Barrel. The rest of my 6.5CM's from 18"-22" all seem to shoot the same load of 40.4grs equally well with the 140 ELD.

Now that I've established my load for the 140 ELD I'll be moving on to the 147 ELD and the Berger 130 AR Hybrid that I'm intentionally going to push as hard as I can to see if I can come close to 3000fps with the 130 and still maintain a low SD and ES.

View attachment 8244323View attachment 8244324View attachment 8244325View attachment 8244326View attachment 8244327View attachment 8244328View attachment 8244329View attachment 8244330View attachment 8244331

Great looking groups. Gives me hope for my gasser and the fact that I might be able to get low numbers as well. What's your plans to push the 130s so fast? I'm considering trying the 123s and 130s for speed as well.

99% of the time I run 140 ELDs and try to find its happy place before pressure signs start to develop. On most of my large frame gassers I use the JP SCS H2 with the full Mass BCG unless it's a Low mass system like I run is my SP10's with a Titanium BCG.

With the 130's I'll bump up the SCS to a H3 and start load development closer to 41.0grs of H4350 or StaBall 6.5 and unless I start seeing a burr develop on the Case Head from the ejector I'll keep moving my charge weight up in .2 increments.

I want to take full advantage of the 24" barrel. 41.0grs of H4350 with the 140 Eld shot pretty decent ( Half MOA) just over 2750fps but I couldn't get it any tighter, while 40.3 maintains in the .3 MOA range.

This is a great thread. I'm continuously doing load development for my AR-10. (.308) Definitely just picked up a few new tidbits of info to try out. I've been doing mostly heavy for caliber loads, and mostly powders that aren't Varget or 4895. Happy to contribute any info I've got.

You won’t get anywhere near 3000fps, let alone 2900fps. If you push much over 2800fps, you’ll start to see cratered primers, ejector extrusion, and overall rough treatment of brass and primers.I recently just finished up load development for one of my Customs that ill be doing a review on here for JP, I went with a 24" Bartlein instead of my usual 22".

The rifle performs quite well between 40 - 41grs of H4350 with the 140 Elds. I settled on 40.3grs for this 24" Barrel. The rest of my 6.5CM's from 18"-22" all seem to shoot the same load of 40.4grs equally well with the 140 ELD.

Now that I've established my load for the 140 ELD I'll be moving on to the 147 ELD and the Berger 130 AR Hybrid that I'm intentionally going to push as hard as I can to see if I can come close to 3000fps with the 130 and still maintain a low SD and ES.

When I went to 42.0gr of H4350 in my .260 Rem gasser under a 130gr Norma even in Lapua brass, I was in the 2824-2879fps range, and it was ugly. I just pulled out my notes:

Cratered primers

Ejector extrusion shearing

Debris embed ???

ES: 54

SD: 19.5

22” Bartlein

42.0 gr H4350

Norma 130gr

Lapua 1x

Winchester LRP

2.810” COL

2855

2824

2879

2851

2836

2826

2838

Yeah I'm not under any illusion that ill actually reach 3000fps but just for shits and giggles i want to see just how close i can get. I've never been one to push my Handloads hard, as you can see from my loads posted above with the 140 ELDs but I thought with the new 24" Bartlein I'd give it a go and see just how hard I can push them before the brass shits the bed and my groups go to shit.You won’t get anywhere near 3000fps, let alone 2900fps. If you push much over 2800fps, you’ll start to see cratered primers, ejector extrusion, and overall rough treatment of brass and primers.

When I went to 42.0gr of H4350 in my .260 Rem gasser under a 130gr Norma even in Lapua brass, I was in the 2824-2879fps range, and it was ugly. I just pulled out my notes:

Cratered primers

Ejector extrusion shearing

Debris embed ???

ES: 54

SD: 19.5

22” Bartlein

42.0 gr H4350

Norma 130gr

Lapua 1x

Winchester LRP

2.810” COL

2855

2824

2879

2851

2836

2826

2838

I've got 3 other Bartlein's in 6.5CM on deck so it's not gonna hurt my feelings if I burn this one out.

You can get a 123gr to 2900fps in the 22”-24” gasser and it will behave much better.

My .260 GAP/Bartlein shoots the 140gr Match Burners, 142gr SMKs, 139gr Scenars, and 130gr Berger VLDs like yours very consistently.

When we did the multi-target demo at BoomerShoot up in Idaho, I would use the .260 Gasser with 130 VLDs to rapidly engage 3-5 explosive targets like a plate rack at 400yds on a cadence. That is particularly fun and memorable, even though I felt demo’d-out by 1995 blowing our Regiment’s entire allotment of C-4, Bangalores, Claymores, Shape Charges, and Det Chord over an 8-day period. I thought I was done enjoying demo after about Day 3 of that, until many years later up at BoomerShoot. Way fun with a .260 Rem Semi Auto precision rifle with 130gr VLDs screaming so flat like they do.

Video of BoomerShoot:

My .260 GAP/Bartlein shoots the 140gr Match Burners, 142gr SMKs, 139gr Scenars, and 130gr Berger VLDs like yours very consistently.

When we did the multi-target demo at BoomerShoot up in Idaho, I would use the .260 Gasser with 130 VLDs to rapidly engage 3-5 explosive targets like a plate rack at 400yds on a cadence. That is particularly fun and memorable, even though I felt demo’d-out by 1995 blowing our Regiment’s entire allotment of C-4, Bangalores, Claymores, Shape Charges, and Det Chord over an 8-day period. I thought I was done enjoying demo after about Day 3 of that, until many years later up at BoomerShoot. Way fun with a .260 Rem Semi Auto precision rifle with 130gr VLDs screaming so flat like they do.

Video of BoomerShoot:

Here’s some .260 Rem load development I did with the 140gr Match Burner and RL-17:

April 12, 2012

Lapua .260 Rem brass, new unfired no prep

Rem 9.5 Primer

RL-17

140gr Barnes Match Burner

2.800” COL

This was just an initial pressure ladder, found an excellent load range out of the gate.

40.0 2574fps

40.2 2628

40.4 2652

40.6 2665

40.8 2699

41.0 2666

41.2 2720

All 7 rounds cut a ragged hole at 100yds, .750” vertical, .389” horizontal. One of them landed higher and opened the group to .750”.

It does the same thing with the 139gr Scenar, but kept shrinking the groups as I increased charge weight when I was shooting 5rd strings per charge weight. I had George cut the throat for the 139gr Scenar at 2.800” COL, sent him the brass I was using initially (Win 7mm-08 necked down).

Everyone told me VLDs wouldn’t shoot out of a gasser, but it loves the 130gr straight Berger VLD (Hybrid AR didn’t exist at the time).

April 12, 2012

Lapua .260 Rem brass, new unfired no prep

Rem 9.5 Primer

RL-17

140gr Barnes Match Burner

2.800” COL

This was just an initial pressure ladder, found an excellent load range out of the gate.

40.0 2574fps

40.2 2628

40.4 2652

40.6 2665

40.8 2699

41.0 2666

41.2 2720

All 7 rounds cut a ragged hole at 100yds, .750” vertical, .389” horizontal. One of them landed higher and opened the group to .750”.

It does the same thing with the 139gr Scenar, but kept shrinking the groups as I increased charge weight when I was shooting 5rd strings per charge weight. I had George cut the throat for the 139gr Scenar at 2.800” COL, sent him the brass I was using initially (Win 7mm-08 necked down).

Everyone told me VLDs wouldn’t shoot out of a gasser, but it loves the 130gr straight Berger VLD (Hybrid AR didn’t exist at the time).

This is 260 Rem:

Sierra 130 SMK CN

Peterson brass - annealed

Federal 210

42.7gr H4350

.004 neck tension SAC .286 Bushing

COAL 2.802

BTO 2.105

.037 jump

Primers are still round, I didn't see any dirty brass or concerning marks on these. I have COAL and BTO somewhere.

Sierra 130 SMK CN

Peterson brass - annealed

Federal 210

42.7gr H4350

.004 neck tension SAC .286 Bushing

COAL 2.802

BTO 2.105

.037 jump

Primers are still round, I didn't see any dirty brass or concerning marks on these. I have COAL and BTO somewhere.

Last edited:

Similar threads

- Replies

- 25

- Views

- 757